ES3

ES3 was founded in 2000 by experienced engineers interested in structuring a company to encourage engineering creativity and excellence. We have offices in San Diego California, Clearfield Utah, and Warner Robins Georgia with additional laboratory facilities in each of the latter two locations as well.

Clearfield, Utah (UT), United States

Aerospace, Defense & Security

Products & Services

People

About

Products & Services

F-16 Services

ES3

ES3 has extensive structural engineering and repair experience in support of the F-16 platform, supporting a wide range of operators in both the United States and in Foreign Military Sales (FMS) markets.

ES3 provides services for F-16 sustainment including engineering assessment, modifications, upgrades, inspections, repairs and enhancements. Our inspection services include structural and electrical assessments as well as on-site support for any Time Compliance Technical Order (TCTO) or major repair related to the airframe. ES3 has been providing support for the F-16 weapon system for more than 15 years and ES3 Staff are experienced in design, engineering analysis, overall airworthiness and structural viability of the platform. Our top three staff members have more than 70 years in combined engineering experience resolving F-16 deficiencies.

ES3 provides services for F-16 sustainment including engineering assessment, modifications, upgrades, inspections, repairs and enhancements. Our inspection services include structural and electrical assessments as well as on-site support for any Time Compliance Technical Order (TCTO) or major repair related to the airframe. ES3 has been providing support for the F-16 weapon system for more than 15 years and ES3 Staff are experienced in design, engineering analysis, overall airworthiness and structural viability of the platform. Our top three staff members have more than 70 years in combined engineering experience resolving F-16 deficiencies.

Parts Supply with Superior Technical and Quality Integration

ES3

The engineering, quality, and inspection expertise of ES3 staff and facilities is available to commercial, foreign, and military clients through ES3 Prime Logistics Group, Inc. (ES3 PLG).

In 2008, ES3 PLG became one of four prime contractors on the US Air Force’s Landing Gear Prime Vendor Contract (LGPVC) providing spare, repair, and consumable components and assemblies for a variety of aircraft landing gear systems. The last orders were placed on LGPVC in April 2018 with continuing deliveries scheduled through December 2026.

In 2018, ES3 PLG became the single awardee on the US Defense Logistics Agency (DLA) Landing Gear Collaborative Supply Chain Integration (LG-CSCI) contract. LG-CSCI is a single award indefinite delivery indefinite quantity (IDIQ) contract with a five-year base period of performance and a five-year option period. Under the LG-CSCI contract, the Government will place delivery orders to meet their requirement for more than 4,500 parts consisting of DLA Landing Gear consumables and US Air Force (USAF) Depot Level Repairables. More information on LG-CSCI along with instructions on how to become a successful supplier under LG-CSCI can be found at Contract Overview and How to Bid on LG-CSCI Orders.

The ES3 PLG Program Manager for both LGPVC and LG-CSCI is Sheridan Kay. Sheridan and her staff oversee all contracting and subcontracting activities, including the solicitation for and evaluation of bids.

ES3 PLG operates under a certified AS9100D(2016) quality management system.

In 2008, ES3 PLG became one of four prime contractors on the US Air Force’s Landing Gear Prime Vendor Contract (LGPVC) providing spare, repair, and consumable components and assemblies for a variety of aircraft landing gear systems. The last orders were placed on LGPVC in April 2018 with continuing deliveries scheduled through December 2026.

In 2018, ES3 PLG became the single awardee on the US Defense Logistics Agency (DLA) Landing Gear Collaborative Supply Chain Integration (LG-CSCI) contract. LG-CSCI is a single award indefinite delivery indefinite quantity (IDIQ) contract with a five-year base period of performance and a five-year option period. Under the LG-CSCI contract, the Government will place delivery orders to meet their requirement for more than 4,500 parts consisting of DLA Landing Gear consumables and US Air Force (USAF) Depot Level Repairables. More information on LG-CSCI along with instructions on how to become a successful supplier under LG-CSCI can be found at Contract Overview and How to Bid on LG-CSCI Orders.

The ES3 PLG Program Manager for both LGPVC and LG-CSCI is Sheridan Kay. Sheridan and her staff oversee all contracting and subcontracting activities, including the solicitation for and evaluation of bids.

ES3 PLG operates under a certified AS9100D(2016) quality management system.

HVOF as an Environmentally Responsible Alternative to Chrome Plating

ES3

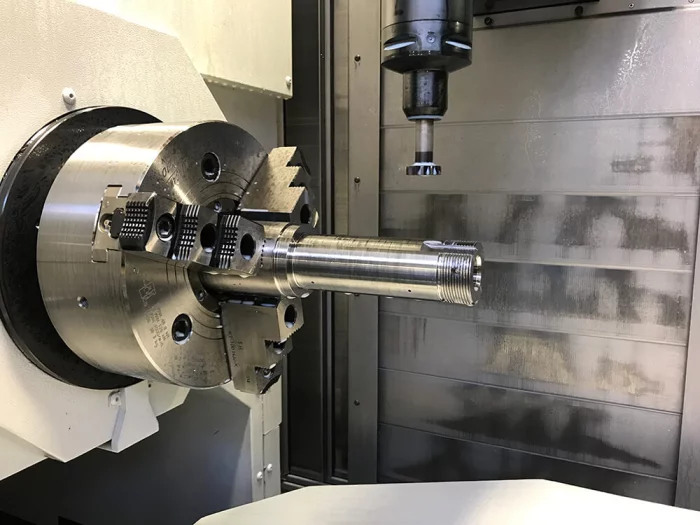

Traditional chrome plating lines produce one of the worst environmental waste streams—hexavalent chrome. Modern and environmentally friendly alternatives are available through High Velocity Oxygenated Fuel (HVOF) coating processes, which are capable of depositing a large variety of materials onto many substrates including high strength steels. These processes are optimized and particularly well-suited for applications requiring wear, heat, and corrosion resistance or dimensional restoration-applications typical for aircraft structural components which have been traditionally hard-chrome plated.

ES3 maintains a state-of-the-art HVOF facility along with engineering and testing staff to define component-specific parameters and procedures for applying advanced surface solutions.

ES3 maintains a state-of-the-art HVOF facility along with engineering and testing staff to define component-specific parameters and procedures for applying advanced surface solutions.

Additive Manufacturing

ES3

ES3 has the technology to provide Additive Manufacturing products, commonly known as 3D printing elements. This is a process of creating a physical object from a digital design by building it layer by layer. It’s the opposite of subtractive manufacturing, where material is removed from a solid block to create an object. ES3 Additive Manufacturing can use various materials, including polymers, metals, and ceramics, and has applications ranging from prototyping to producing functional parts for industries like aerospace.

Landing Gear

ES3

ES3 provides technical expertise in all aspects of landing gear systems research, test and evaluation, design and analysis, repair and maintenance. ES3 staff has an exceptional history and understanding of landing gear issues, problem components, and promising technologies. Specifically, our capabilities and support services encompass:

Landing gear structural components;

Material science to include new material development;

Hydraulic and steering systems;

Policies and regulations for management of landing gear systems, including their technical and reprocurement part data and the software which manages that data;

Manufacturing processes for landing gear components including all aspects of the procurement supply chain;

Repair and overhaul processes for landing gear systems, including the review, verification, and modification of new processes for improved system sustainment;

Strategies for proactive and targeted quality assurance and six sigma practices;

Advanced analytical methods to include structural mechanics for static and dynamic modeling

Landing gear structural components;

Material science to include new material development;

Hydraulic and steering systems;

Policies and regulations for management of landing gear systems, including their technical and reprocurement part data and the software which manages that data;

Manufacturing processes for landing gear components including all aspects of the procurement supply chain;

Repair and overhaul processes for landing gear systems, including the review, verification, and modification of new processes for improved system sustainment;

Strategies for proactive and targeted quality assurance and six sigma practices;

Advanced analytical methods to include structural mechanics for static and dynamic modeling

Surface Finishing

ES3

Surface finishing imparts characteristics that enhance performance and longevity on components and assemblies. In aerospace and other heavy industries, surface finishing can eliminate surface defects, increase wear resistance, reduce friction, increase strength, reduce corrosion, extend life, and reduce life cycle costs not just for the component but also for the assemblies and systems that component supports. ES3 has been working in surface finishing for more than 20 years. Our efforts span R&D of new surface finishing technologies through development, certification, and implementation.

ES3 has incorporated an advanced electroplating technique into its conformal anode design using the Swivel Rocker FixtureTM (US patent 11,274,378), which agitates the part during electroplating eliminating gas bubble pockets that form and prevent plating in recessed or internal areas.

ES3 has incorporated an advanced electroplating technique into its conformal anode design using the Swivel Rocker FixtureTM (US patent 11,274,378), which agitates the part during electroplating eliminating gas bubble pockets that form and prevent plating in recessed or internal areas.

Multiphysics Analyses of the Response of Structures (MARS) Solver

ES3

The MARS computational framework for performing Multiphysics Analyses of the Response of Structures has a number of unique features that make it one of the most versatile and powerful platforms available.

Most commercially available computational frameworks are built around a specific discretization scheme and solution algorithm, thus limiting the range of applications and ability to deal with emerging computational challenges and approaches. Furthermore, customization of available constitutive models, element formulations, contact conditions or solvers is typically quite limited, necessitating the use of external scripts to extend capabilities. The latter, if even possible, leads to significant performance reductions.

MARS on the other hand has been developed in a modular way, making use of the computational efficiency but also core capabilities of the object-orientated coding language C++ such as abstraction, encapsulation, inheritance, and polymorphism. This makes it possible to seamlessly integrate different discretization schemes, constitutive models, contact conditions, and solvers.

Most commercially available computational frameworks are built around a specific discretization scheme and solution algorithm, thus limiting the range of applications and ability to deal with emerging computational challenges and approaches. Furthermore, customization of available constitutive models, element formulations, contact conditions or solvers is typically quite limited, necessitating the use of external scripts to extend capabilities. The latter, if even possible, leads to significant performance reductions.

MARS on the other hand has been developed in a modular way, making use of the computational efficiency but also core capabilities of the object-orientated coding language C++ such as abstraction, encapsulation, inheritance, and polymorphism. This makes it possible to seamlessly integrate different discretization schemes, constitutive models, contact conditions, and solvers.

Zinc Nickel as an Environmentally Preferred Alternative to Cad Plating

ES3

ES3 has developed, qualified, and implemented LHE alkaline Zinc-Nickel (Zn-Ni) Dipsol IZ-C17+ plating on high strength steels which meet Cd plate baseline corrosion prevention, fatigue, and HE objectives. This LHE Zn-Ni process enables aerospace manufacturing to meet environmental restrictions by eliminating Cd waste streams. Zn-Ni is a cyanide free plating process that meets the requirements for a non-embrittling process per ASTM F519. The LHE Zn-Ni process has excellent throwing power in both plating and corrosion protection. The coating consists of a uniform zinc alloy containing 12-18% nickel. LHE Zn-Ni is applicable to aircraft major structural components, such as pistons, cylinders, truck beams, torque arms, and axles as well as consumables such as pins, bearings, bushings, and bolts.

MRO to military and commercial fixed-wing and rotary wing aircraft

ES3

ES3 staff is experienced in providing engineering MRO structural, system, electrical, avionics and powerplant repair and overhaul support, as well as managed groups responsible for engineering support activities for Lockheed, Airbus, Boeing, Douglas and Bombardier aircraft. This included depot level and flight line support for domestic and international facilities, including incident recovery and failure analysis. ES3 maintenance staff includes A&P licensed and certified inspectors, military and commercial system and sheet metal mechanics, as well as highly skilled/certified technicians for all aircraft structural repair including welding, tube and hose assembly, wiring, soldering, machining, thermal spray, plating, NDT (including level three), etc.

Landing Gear Diagnostics and Prognostics

ES3

ES3 has successfully deployed an On-Board Weight and Balance System (OBWBS). The ES3 OBWBS has been operational for more than 4 years on a fleet of 15 heavy military rotorcraft. During that time, accuracy better than plus or minus 3% gross weight has been achieved and all Reliability, Availability, and Maintainability (RAM) goals have been exceeded. The ES3 technology is not just a good concept; it is ready and proven.

ES3 Testing, Diagnostics, and Analysis

ES3

ISO 17025 is an internationally recognized laboratory test standard and the authoritative standard for demonstrating laboratory test competence. ES3’s Georgia Technical Operations Center (GTOC) located in Warner Robins, Georgia maintains a certificate of accreditation in ISO17025 testing, enabling us to demonstrate that we:

operate with competency and consistency across equipment, technicians, scientists, and engineers, and

generate accurate and valid test results.

ES3 has the ability to perform testing on eight (8) different tests in accordance with the American Society for Testing and Materials (ASTM) standards.

operate with competency and consistency across equipment, technicians, scientists, and engineers, and

generate accurate and valid test results.

ES3 has the ability to perform testing on eight (8) different tests in accordance with the American Society for Testing and Materials (ASTM) standards.

People

About

ES3 is an aerospace engineering company specializing in the design, development, and manufacture of landing gear systems. For more than 20 years, ES3 has been the system integrator for redesign, flight qualification, and fleet retrofits on landing gear systems that include structures, hydraulics, and rolling stock (wheels, brakes, and antiskid).

ES3 is the Original Equipment Manufacturer (OEM) of Onboard Weight and Balance Systems (OBWBS) with more than five years of in-fleet service and an outstanding record of performance and reliability. We are a Maintenance, Repair, and Overhaul (MRO) provider for such platforms as C-5 airframes and F-16 wings, including structural upgrades and modifications. ES3 scientists have successfully developed physics-based, high-fidelity software that assists our engineers in performing advanced computational simulations for (1) the response of structures to extreme loading conditions involving a variety of materials including our continuous fiber composite structures and (2) the precise deposition of coatings on electroplated surfaces involving our patented conformal anode fixture designs. ES3 develops new materials and processes for aerospace that are environmentally responsible. Our highly engineered advanced coating and electroplating systems have been installed in a variety of facilities at aerospace OEMs and overhaulers, eliminating tons of highly toxic cadmium and hexavalent chrome from aerospace processing.

ES3 enjoys a corporate culture that values engineering excellence above all else. As a result, we deliver rewarding work experiences to our staff and responsive project teams to our customers.

ES3 is the Original Equipment Manufacturer (OEM) of Onboard Weight and Balance Systems (OBWBS) with more than five years of in-fleet service and an outstanding record of performance and reliability. We are a Maintenance, Repair, and Overhaul (MRO) provider for such platforms as C-5 airframes and F-16 wings, including structural upgrades and modifications. ES3 scientists have successfully developed physics-based, high-fidelity software that assists our engineers in performing advanced computational simulations for (1) the response of structures to extreme loading conditions involving a variety of materials including our continuous fiber composite structures and (2) the precise deposition of coatings on electroplated surfaces involving our patented conformal anode fixture designs. ES3 develops new materials and processes for aerospace that are environmentally responsible. Our highly engineered advanced coating and electroplating systems have been installed in a variety of facilities at aerospace OEMs and overhaulers, eliminating tons of highly toxic cadmium and hexavalent chrome from aerospace processing.

ES3 enjoys a corporate culture that values engineering excellence above all else. As a result, we deliver rewarding work experiences to our staff and responsive project teams to our customers.

Add Attachment

Share

Recent Chats

Share via email

Future: handle WhatsApp here

Future: handle LinkedIn here

Future: handle Twitter here

SUBMENU HERE

Share via Chat

Copy Link