_300.webp)

POLAR POWER INC

Gardena, California (CA), United States

Aerospace

+1 (310) 830-9153

Products & Services

People

About

Products & Services

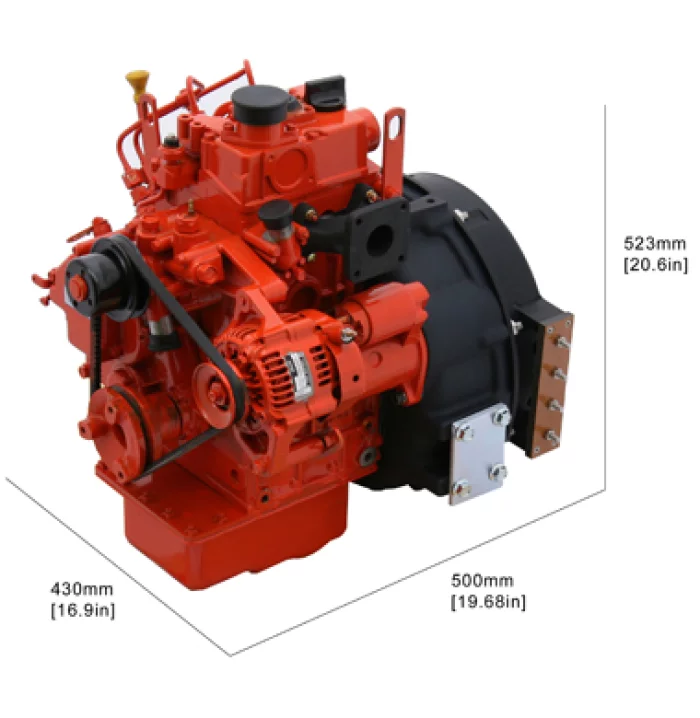

8080P-40205 5.5 KW DIESEL DC GENERATOR

Polar Power Inc

The Most Efficient Means to Charge Batteries and Power Loads using Diesel

Fully Automatic Battery Charging Options

Features

Maximum Continuous Output: 5.5 kW at 2900 RPM

100 amps at 54 Vdc (200 amps at 28 Vdc)

Variable speed with 500 RPM span – full load to no load

Lower engine speed options available

2 cylinder diesel, water cooled

Engine Operational Life: 8,000 to 12,000 hours

Temperature compensated battery charging

Oil changes at 500 hours with 1,500 hour maintenance option

Available with electric water pump in a beltless configuration

Very light weight – 195 pounds without controls

Fully Automatic Battery Charging Options

Features

Maximum Continuous Output: 5.5 kW at 2900 RPM

100 amps at 54 Vdc (200 amps at 28 Vdc)

Variable speed with 500 RPM span – full load to no load

Lower engine speed options available

2 cylinder diesel, water cooled

Engine Operational Life: 8,000 to 12,000 hours

Temperature compensated battery charging

Oil changes at 500 hours with 1,500 hour maintenance option

Available with electric water pump in a beltless configuration

Very light weight – 195 pounds without controls

6200 SERIES DC ALTERNATORS

Polar Power Inc

Polar Power first tested its DC Alternator using its Permanent Magnet Hybrid Homopolar (PMHH) technology in 1992. Since then numerous organizations have performed extensive testing on Polar’s generators, including the US Military.

Polar Power has met these performance goals through an integrated engineering effort involving detailed analysis of engine, voltage regulation electronics, field coil, magnet, stator, rotor, and diode effects on the generators output voltage, current, and electrical quality.

Polar Power selected and optimized the 6200 series alternator using our PMHH technology because it does not require brushes, slip rings, rotating fields, exciters, or field flashing. Its small and compact design allows the use of a bearing-less pancake design.

Polar Power has met these performance goals through an integrated engineering effort involving detailed analysis of engine, voltage regulation electronics, field coil, magnet, stator, rotor, and diode effects on the generators output voltage, current, and electrical quality.

Polar Power selected and optimized the 6200 series alternator using our PMHH technology because it does not require brushes, slip rings, rotating fields, exciters, or field flashing. Its small and compact design allows the use of a bearing-less pancake design.

About

We design and manufacture power and cooling systems for targeted market applications. In particular, we offer DC power systems, DC hybrid power systems, and DC solar hybrid power systems for telecommunications, military, renewable energy, marine, automotive and oil field applications. Our solutions provide reliable and low-cost energy for applications that do not have access to the utility grid or will continue to power applications in the event of utility grid failure.

We were incorporated in the state of Washington in 1979 under the name Polar Products. To more specifically target the power systems industry, we changed our name to Polar Power Inc in 1991 and during this process we reincorporated in the state of California. Our corporate headquarters are located in Gardena, California.

Our first product, a solar powered vaccine refrigerator/freezer for use in remote areas worldwide, was manufactured at our former Bellingham, Washington facility. This product was developed in support of a World Health Organization initiative and the U.S. Agency for International Development. This project was administered by the NASA Lewis Research Center.

Since then, we have continued to expand our capabilities and product lines within the solar and renewable energy industries. Historically, solar powered products and systems developed and manufactured by us included voltage regulators, charge controllers, ice plants, freezers and refrigerators, water pumps, lighting, cathodic protection, telecommunication power systems, and ultra-low temperature freezers.

We expanded our services in 1984 to include the design and manufacturing of manual and automated test systems for the aerospace industry. We supplied Coolanol test carts required for testing F- 14 radar assemblies to Hughes Aircraft. We also produced computerized environmental control units for production testing of laser guided missile launch systems for Martin Marietta.

For General Dynamics, we engineered and prototyped an innovative cooling system for the Phalanx Gun system. In 1984, we were awarded a contract by the U.S. Army to develop and manufacture a high reliability battery charger for use as part of a security system in nuclear arsenals. Other contracts followed from the U.S. Air Force, Army, Navy and Defense Logistics Agency for DC generators, power supplies, and cooling systems.

Until 1992, we purchased DC alternators that were essentially reconfigured AC alternators. These units were large, heavy, and inefficient. Dissatisfied with the technologies available at the time, we developed an advanced permanent magnet hybrid homopolar alternator that met stringent U.S. specifications. In 1995, the U.S. Department of Defense described our product as the most advanced generator in production.

With the exponential growth of the telecommunications sector in the early 1990s, we strategically shifted our efforts away from manufacturing products primarily for military applications to focus more on the telecommunications industry. We were one of the first to introduce DC power systems and micro-cogeneration systems that provided both power and cooling within the same package into the telecommunications market.

During the last 10 years we have developed numerous proprietary technologies in an effort to improve our product performance and aid the expansion of our power solutions. We have also made substantial investments in our tooling and machinery - resulting in a significant reduction of our production costs.

We were incorporated in the state of Washington in 1979 under the name Polar Products. To more specifically target the power systems industry, we changed our name to Polar Power Inc in 1991 and during this process we reincorporated in the state of California. Our corporate headquarters are located in Gardena, California.

Our first product, a solar powered vaccine refrigerator/freezer for use in remote areas worldwide, was manufactured at our former Bellingham, Washington facility. This product was developed in support of a World Health Organization initiative and the U.S. Agency for International Development. This project was administered by the NASA Lewis Research Center.

Since then, we have continued to expand our capabilities and product lines within the solar and renewable energy industries. Historically, solar powered products and systems developed and manufactured by us included voltage regulators, charge controllers, ice plants, freezers and refrigerators, water pumps, lighting, cathodic protection, telecommunication power systems, and ultra-low temperature freezers.

We expanded our services in 1984 to include the design and manufacturing of manual and automated test systems for the aerospace industry. We supplied Coolanol test carts required for testing F- 14 radar assemblies to Hughes Aircraft. We also produced computerized environmental control units for production testing of laser guided missile launch systems for Martin Marietta.

For General Dynamics, we engineered and prototyped an innovative cooling system for the Phalanx Gun system. In 1984, we were awarded a contract by the U.S. Army to develop and manufacture a high reliability battery charger for use as part of a security system in nuclear arsenals. Other contracts followed from the U.S. Air Force, Army, Navy and Defense Logistics Agency for DC generators, power supplies, and cooling systems.

Until 1992, we purchased DC alternators that were essentially reconfigured AC alternators. These units were large, heavy, and inefficient. Dissatisfied with the technologies available at the time, we developed an advanced permanent magnet hybrid homopolar alternator that met stringent U.S. specifications. In 1995, the U.S. Department of Defense described our product as the most advanced generator in production.

With the exponential growth of the telecommunications sector in the early 1990s, we strategically shifted our efforts away from manufacturing products primarily for military applications to focus more on the telecommunications industry. We were one of the first to introduce DC power systems and micro-cogeneration systems that provided both power and cooling within the same package into the telecommunications market.

During the last 10 years we have developed numerous proprietary technologies in an effort to improve our product performance and aid the expansion of our power solutions. We have also made substantial investments in our tooling and machinery - resulting in a significant reduction of our production costs.

Add Attachment

Share

Recent Chats

Share via email

Future: handle WhatsApp here

Future: handle LinkedIn here

Future: handle Twitter here

SUBMENU HERE

Share via Chat

Copy Link