DRILLING EQUIPMENT

BOPS, BALL VALVES, CHOCKES, CHECK VALVES, CUSTOM DESIGNED SYSTEMS, CONTROL PANELS, GATE VALVES

WELL TESTING EQUIPMENT

SURFACE SAFETY VALVE, TRAILER MOUNTED EQUIPMENT, FLOW CATCHER MANIFOLDS, ALL WELL TEST EQUIPMENT

REPAIR, RECIRTIFICATION AND REBRANDING

WELL HEADS, CHOKE AND KILL MANIFOLDS, FLOW IRONM FLOW BACK, BLOWOUT PREVENTORS AND RAM BLOCKS

PRODUCTION EQUIPMENT

WELLHEADS& CHRISTMAS TRESS, EMERGENCY SHUTDOWN SYSTEM

WORLDWIDE OILFIELD MACHINE

See us at ADIPEC 2026 · Booth: 8135

Worldwide Oilfield Machine (WOM) is a globally recognized, multinational company. We are a fully vertically integrated entity, which allows us to ensure the highest level of quality control in every aspect of the manufacturing process.

Houston, Texas (TX), United States

Oil · Gas · Energy

Products & Services

People

About

Connect with us at

Products & Services

TECHNICAL BUILDING

Worldwide Oilfield Machine

Our high quality customized technical buildings are engineered to the highest standards complying to major oil & gas industry specifications. Products include Substations, Local Equipment Rooms, Local Control Rooms, Control Rooms, Electrical Power Skids, E-house, Battery rooms, Switch Gear Rooms etc. As per client requirements these buildings are certified for fire ratings and includes complete controlled environment for client cabinets, control system, any other systems and equipment.

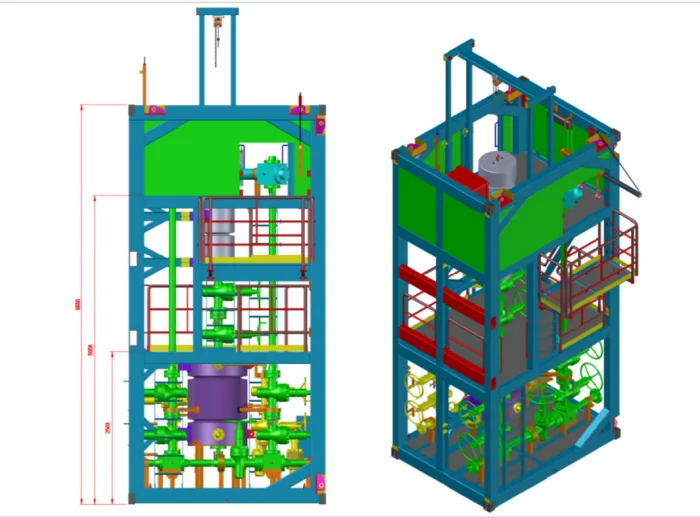

Desander

Worldwide Oilfield Machine

The MTC design format is composed of a combination of upper pressure vessels for insert

fitting and a lower pressure vessel for solid accumulation. The associated valves and

manifold are also installed in a compact lifting frame to provide the equipment with mobile

characteristics for offshore / onshore applications and also for direct mounting on trailer units

when required.

Additional Technical Details

The container frame that houses the vessels and manifold includes a full drip pan in the

base section with drain outlets on both sides of the frame. Grating is installed on top of the drip

pan to allow safe working around the vessels, manifold and valves.

A large upper working area is recessed into the upper section of the container frame with

access ladders each end and handrails to allow safe working conditions. An integrated extending

crane beam over the central vessels area fitted with a set of manual chain block hoists which is

included to allow removal of the vessel top connection cap and the inserts. A large lockable

oilfield sized toolbox is also included in this upper working area for local storage of special and

standard hand tools etc.

The instrumentation package consists of an external load cell system with a baseline

offer of HMI web based with cabled and wi-fi access. A post processor software is part of

the loadcell solution, to allow an improved dynamic answer.

The online sizing tool is also available upon request with unlimited number of

simulations.

fitting and a lower pressure vessel for solid accumulation. The associated valves and

manifold are also installed in a compact lifting frame to provide the equipment with mobile

characteristics for offshore / onshore applications and also for direct mounting on trailer units

when required.

Additional Technical Details

The container frame that houses the vessels and manifold includes a full drip pan in the

base section with drain outlets on both sides of the frame. Grating is installed on top of the drip

pan to allow safe working around the vessels, manifold and valves.

A large upper working area is recessed into the upper section of the container frame with

access ladders each end and handrails to allow safe working conditions. An integrated extending

crane beam over the central vessels area fitted with a set of manual chain block hoists which is

included to allow removal of the vessel top connection cap and the inserts. A large lockable

oilfield sized toolbox is also included in this upper working area for local storage of special and

standard hand tools etc.

The instrumentation package consists of an external load cell system with a baseline

offer of HMI web based with cabled and wi-fi access. A post processor software is part of

the loadcell solution, to allow an improved dynamic answer.

The online sizing tool is also available upon request with unlimited number of

simulations.

WOM Pressure Control Equipment- PCE

Worldwide Oilfield Machine

WOM manifold systems may incorporate WOM’s Magnum gate valves, check

valves, plug valves, chokes, and WOM actuators depending upon the application.

WOM manifold designs meet virtually any industry requirement, including H2S environments up

to 20,000 psi. Skid mounted and fully automated packages are available complete with control

panels and instrumentation.

WOM “WU” BOP is the most widely used BOP type in the world today. Its simple, compact design makes it well suited for operations offshore and onshore. WOM’s ram type “WU” BOP operating system is designed to provide a fast and reliable closure around pipe or casing in the well bore. The sealing is energized by the pressure and is maintained even with loss of closing pressure.

valves, plug valves, chokes, and WOM actuators depending upon the application.

WOM manifold designs meet virtually any industry requirement, including H2S environments up

to 20,000 psi. Skid mounted and fully automated packages are available complete with control

panels and instrumentation.

WOM “WU” BOP is the most widely used BOP type in the world today. Its simple, compact design makes it well suited for operations offshore and onshore. WOM’s ram type “WU” BOP operating system is designed to provide a fast and reliable closure around pipe or casing in the well bore. The sealing is energized by the pressure and is maintained even with loss of closing pressure.

High Integrity Pressure Protection System

Worldwide Oilfield Machine

HIPPS and emergency shutdown (ESD) capabilities that protect personnel and the environment while helping to mitigate financial and operational risk. WOM V&C is an industry leading resource for HIPPS and ESD technologies, turnkey solutions and global service. Our scope of technology includes valves, manifolds, actuators and controls, enclosures, transmitters and logic solvers.

Offshore & Onshore maintenance works- Prefabricated Modular Buildings

Worldwide Oilfield Machine

• Offshore & Onshore maintenance works: Our dedicated skilled technicians are available to carry out maintenance works both Offshore & Onshore on immediate basis. Highly skilled technicians can carry out works related to HVAC and E&I works at both locations.

• HVAC, Electrical & Instrumentation works: Our dedicated skilled technicians are available to carry out HVAC, Electrical & Instrumentation works for both Offshore & Onshore areas.

• Maintenance, Repair, Refurbishment works: Our dedicated skilled technicians are available to carry out Maintenance, Repair, Refurbishment works for both Offshore & Onshore areas.

• Design, Engineering & Drafting services: Our expert Engineering team are available to carry out Design, Engineering & Drafting for turnkey projects.

• Prefabricated Modular Buildings: We are specialized in design and manufacture of Prefabricated Modular type of technical buildings, that include E-houses, Substations, LER’s, LCR’s, Operator cabins, Blast Resistant Buildings etc. Our modular buildings are manufactured in accordance with major International standards like NFPA 496, ATEX, IECEx, NORSOK and or any other applicable codes. The modules can be built in standard or customized and can be certified by renowned third-party agencies like DNV, ABS, BV, Lloyd’s. As an experienced manufacturer and solution provider, you can be assured that your products will be designed, developed, and manufactured to the highest standards to cater harsh weather conditions, hazardous & safe area. Modules includes Mud Logging Units (MLU), Measuring While Drilling (MWD), Drillers cabins, Office, Laboratories, Workshops, Storage, Accommodation, Chiller/Freezer, Kitchens, Lavatories and can be designed & manufactured to cater Blast Resistance also.

• Skid Mounted Process Equipment: We are specialized in providing integrated package solutions for the service companies and operators for their Well Testing, Under Balanced Drilling, Managed Pressure Drilling and & Early Production Facility. Our capabilities also includes the manufacturing of pressure vessel with ASME U, U2 & R certificates. We also offer skid/trailer mounted equipment packages such as Separators, Surge Tanks, Sand Management Systems, Burner Booms, Steam Exchangers, Chemical Injection Packages, Piping/Pump packages etc.

• HVAC, Electrical & Instrumentation works: Our dedicated skilled technicians are available to carry out HVAC, Electrical & Instrumentation works for both Offshore & Onshore areas.

• Maintenance, Repair, Refurbishment works: Our dedicated skilled technicians are available to carry out Maintenance, Repair, Refurbishment works for both Offshore & Onshore areas.

• Design, Engineering & Drafting services: Our expert Engineering team are available to carry out Design, Engineering & Drafting for turnkey projects.

• Prefabricated Modular Buildings: We are specialized in design and manufacture of Prefabricated Modular type of technical buildings, that include E-houses, Substations, LER’s, LCR’s, Operator cabins, Blast Resistant Buildings etc. Our modular buildings are manufactured in accordance with major International standards like NFPA 496, ATEX, IECEx, NORSOK and or any other applicable codes. The modules can be built in standard or customized and can be certified by renowned third-party agencies like DNV, ABS, BV, Lloyd’s. As an experienced manufacturer and solution provider, you can be assured that your products will be designed, developed, and manufactured to the highest standards to cater harsh weather conditions, hazardous & safe area. Modules includes Mud Logging Units (MLU), Measuring While Drilling (MWD), Drillers cabins, Office, Laboratories, Workshops, Storage, Accommodation, Chiller/Freezer, Kitchens, Lavatories and can be designed & manufactured to cater Blast Resistance also.

• Skid Mounted Process Equipment: We are specialized in providing integrated package solutions for the service companies and operators for their Well Testing, Under Balanced Drilling, Managed Pressure Drilling and & Early Production Facility. Our capabilities also includes the manufacturing of pressure vessel with ASME U, U2 & R certificates. We also offer skid/trailer mounted equipment packages such as Separators, Surge Tanks, Sand Management Systems, Burner Booms, Steam Exchangers, Chemical Injection Packages, Piping/Pump packages etc.

People

Connect with us at

About

Worldwide Oilfield Machine (WOM) is a multinational equipment manufacturer specializing in solutions for drilling, testing, production and intervention operations. Our reliable oilfield products are used onshore, offshore, and in subsea applications throughout the industry, including in high pressure and extreme temperature environments.

WOM started in 1980 with just a handful of employees in Houston, Texas. Today, that number has grown to nearly 3,000 employees in locations spanning across 10 countries… and we’re still growing! Our diverse workforce supports manufacturing facilities, engineering centers, assembly/testing locations, and more. WOM also provides aftermarket services like onsite crews for installation, inspection, and repair.

WOM started in 1980 with just a handful of employees in Houston, Texas. Today, that number has grown to nearly 3,000 employees in locations spanning across 10 countries… and we’re still growing! Our diverse workforce supports manufacturing facilities, engineering centers, assembly/testing locations, and more. WOM also provides aftermarket services like onsite crews for installation, inspection, and repair.

Add Attachment

Share

Recent Chats

Share via email

Future: handle WhatsApp here

Future: handle LinkedIn here

Future: handle Twitter here

SUBMENU HERE

Share via Chat

Copy Link