KANEY AEROSPACE

Kaney Inc. is an AS9100 certified engineering, manufacturing and technology company headquartered in Rockford, Illinois, with operations globally. Its product offerings include high-precision, high-reliability motion and position-control actuation solutions, test equipment, aircraft harnesses, laboratory architecture and operation, large-scale systems integration test and system engineering serving Aerospace, Defense, Medical and UAV/UAM markets.

Rockford, Illinois (IL), United States

Aerospace

Products & Services

People

About

Products & Services

Iridium Linear Actuator

Kaney Aerospace

Compact linear actuator

Smart Servo

Kaney Aerospace

Flight Critical High Reliability Fail Safe Smart Servo

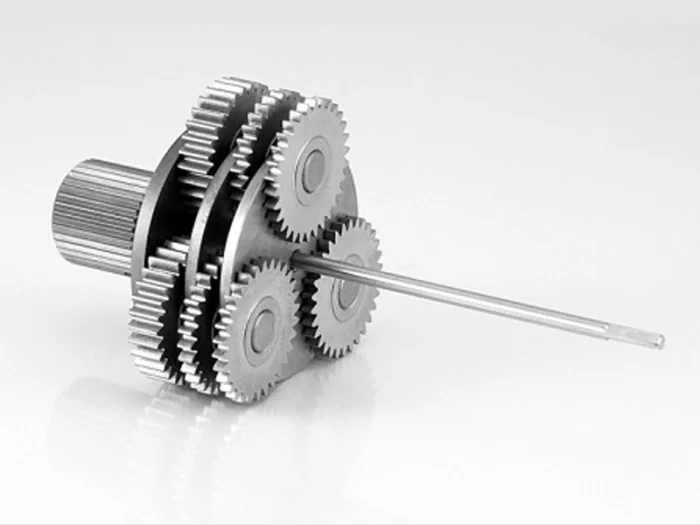

Geartrain

Kaney Aerospace

Planetary High Accuracy Geartrain

Rotary to Linear Actuator

Kaney Aerospace

Single-axis actuator with brushless DC motor

Rotary Actuator Controller

Kaney Aerospace

Dual-Axis Actuator and Position Module

DEFENSE

Kaney Aerospace

Our Kaney Technical Field Office in Dayton, Ohio specializes in advanced technologies Small Business Innovative Research (SBIR) activity. We actively partner with the world’s leading Tier 1 and Airframers in targeting our SBIR activities to their needs. Our capabilities include test facility architecture/operations, test lab conformity, test equipment design & build for development and production, DO-160 test planning & execution, DO-254, DO-178, ARP 4754A and ARP 4761 compliance, simulation & modeling, structural & stress analysis, quality assurance, project / program management, SolidWorks, CATIA, LabView, C / C++, production & test wiring harness assembly, and CNC manufacturing. Our KTFO staff includes industry leaders in integrated power and thermal solutions, motion control, electric propulsion, material science, system certification. The KTFO includes on-site rapid response capability for development hardware assembly, test and evaluation with direct access to the comprehensive engineering and manufacturing capabilities at Kaney’s 55,000 square foot headquarters in Rockford IL.

270 VDC High Power-Quality Generator

Kaney Aerospace

270 VDC High Power-Quality Generator

Aerospace Pneumatic Valve Test Stand

Kaney Aerospace

Kaney has been an integral part of the hardware, software, and physical architecture and operation of the world’s most advanced system integration labs, from the 787 aircraft electric power system to the world’s most advanced aerial mobility vehicles. Our systems-centric approach provides an understanding of the unique needs of every aerospace project and has made us a worldwide preferred solution on platforms such as 787, G500/G600, 777x, multiple AAM platforms, and complete copper and iron birds.

Aerospace, Medical & Industrial Instrumentation Harnesses

Kaney Aerospace

At Kaney, we combine our expertise, experience and advanced digital engineering to design and construct state-of-the-art system integration laboratories that allow for the testing and validation of high-voltage electric propulsion systems, complex avionics, actuation, communication, navigation, environmental, and thermal control systems. Our lab operations range from development of aircraft systems far into the future to labs used for FAA/EASA certification today.

Utility Actuator

Kaney Aerospace

Single-axis actuator with brushless DC Motor

People

About

Kaney is a systems centric, vertically integrated manufacturing and engineering company with a history of creating comprehensive lifecycle solutions for our valued customers’ most challenging problems. We create value by intense understanding of our customer needs and then leveraging our deep systems expertise, advanced technology, unmatched intellectual resources and full-capability lean manufacturing.

With over 110 team members, our staff includes 20+ degreed electrical, mechanical, software, and aerospace engineers and physicists ranging from recent graduates to Ph. D level experts. Kaney provides full product life cycle solutions from system level architecture, new product development, entry into service, FAA systems level certification, iron bird/laboratory services and FAA-145 aftermarket repair.

Our success is driven by:

A foundation of safety and quality

People who perform

Processes that enable

Unfailing integrity, professionalism and excellence in all we do

Continuous, meticulous and uncompromising protection of our customers’ Intellectual property

Our aerospace products are flying in commercial and defense applications worldwide and include motion control and autopilot actuation systems, electric brake systems, cockpit controls and instrumentation. Our actuators and servos include embedded DO-178 Level A software that enables flexibility in applications ranging from the cockpit to critical flight control surfaces. Our smart servos have become integral to the development and flight testing of Advanced Air Mobility (AAM) platforms, both in pilot-optional and fully autonomous vehicles. We are an FAA CFR Part 145 and EASA licensed repair station.

We supply tens of thousands of products each year to medical device manufacturers worldwide. Our medical devices include AGMA 14 quality gear and gearboxes, complete motion control and actuation systems. Applications include robotic solutions for both devices and patient transport, automatic CPR equipment, robotic sample handling, dental drill precision gears and orthopedic surgical drills and mills.

We specialize in technically difficult and high value engineering services. Our team includes unparalleled expertise in many areas including:

System architecture / system specification creation

Prescriptive guidance for product, system and airframe certification

Electric power systems including:

Electric/hybrid propulsion

Power generation, distribution and control

Thermal management of both crew and equipment

Autonomous flight controls and fight management

Software design and certification in accordance with DO-178 and DO-254

Specialized test equipment

Cables and harnesses

FAA conformity for system integration labs and iron birds

With over 110 team members, our staff includes 20+ degreed electrical, mechanical, software, and aerospace engineers and physicists ranging from recent graduates to Ph. D level experts. Kaney provides full product life cycle solutions from system level architecture, new product development, entry into service, FAA systems level certification, iron bird/laboratory services and FAA-145 aftermarket repair.

Our success is driven by:

A foundation of safety and quality

People who perform

Processes that enable

Unfailing integrity, professionalism and excellence in all we do

Continuous, meticulous and uncompromising protection of our customers’ Intellectual property

Our aerospace products are flying in commercial and defense applications worldwide and include motion control and autopilot actuation systems, electric brake systems, cockpit controls and instrumentation. Our actuators and servos include embedded DO-178 Level A software that enables flexibility in applications ranging from the cockpit to critical flight control surfaces. Our smart servos have become integral to the development and flight testing of Advanced Air Mobility (AAM) platforms, both in pilot-optional and fully autonomous vehicles. We are an FAA CFR Part 145 and EASA licensed repair station.

We supply tens of thousands of products each year to medical device manufacturers worldwide. Our medical devices include AGMA 14 quality gear and gearboxes, complete motion control and actuation systems. Applications include robotic solutions for both devices and patient transport, automatic CPR equipment, robotic sample handling, dental drill precision gears and orthopedic surgical drills and mills.

We specialize in technically difficult and high value engineering services. Our team includes unparalleled expertise in many areas including:

System architecture / system specification creation

Prescriptive guidance for product, system and airframe certification

Electric power systems including:

Electric/hybrid propulsion

Power generation, distribution and control

Thermal management of both crew and equipment

Autonomous flight controls and fight management

Software design and certification in accordance with DO-178 and DO-254

Specialized test equipment

Cables and harnesses

FAA conformity for system integration labs and iron birds

Add Attachment

Share

Recent Chats

Share via email

Future: handle WhatsApp here

Future: handle LinkedIn here

Future: handle Twitter here

SUBMENU HERE

Share via Chat

Copy Link