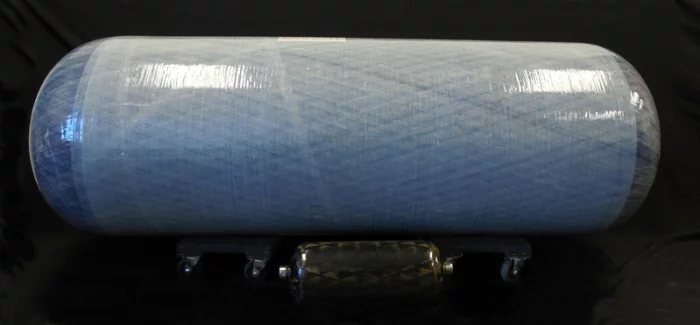

COPV Composite Pressure Vessels

Leaders in design, analysis, qualification and production of type III,IV,V pressure vessels

Experience

Founded in 1996 with years of direct engineering experience with composite pressure vessels

AS9100D Certified

Quality Management System to ensure the finest quality product

Capabilities

Pressure vessel design, FEA, In-house development and fabrication, in-house pressure vessel testing

HYPERCOMP

HyPerComp Engineering, Inc. is an industry leader in the development, testing, qualification, and production of Composite Overwrapped Pressure Vessels (COPVs). Our products are used in space launch vehicles, commercial & military drones (aerial & underwater), other hydrogen fuel-cell and electrolysis technologies, and in many other exciting applications throughout the world. We design, fabricate, and test each of our products in Brigham City, UT. Our small team (less than 20 employees) is tight-knit and we love what we do. One of the best parts of HyPerComp is the exciting testing we get to do (it’s kinda like myth-busters around here). We are an AS9100 D company and our commitment to safety is our highest priority.

Brigham City, Utah (UT), United States

Aerospace, Defense & Security, Oil · Gas · Energy

Products & Services

People

About

Products & Services

Natural Gas

HyPerComp

HEI’s reputation within the space industry for Hydrogen COPV innovation attracted the world’s early adapters of Hydrogen for on-board use of automotive Hydrogen for fuel storage. HEI successfully supplied the first “proof of concept” extreme high pressure gaseous and cryogenic compressed Hydrogen automotive solutions to the global leaders of automotive OEMs in the early adaption of Hydrogen COPVs and their proof-of-concept success. We have successfully demonstrated capabilities in cryogenic compressed Hydrogen as well as very high pressure gaseous hydrogen, of which there is a representative top-level summary below. Specifics are available to our clients on a case-by-case basis.

Damage Tolerance

HyPerComp

HyPerComp has developed a "benign-failure-mode" capability which greatly reduces the likelihood of catastrophic pressure vessel failures resulting in injury or death. This technology has demonstrated the ability of a composite pressure vessel to survive the impact of a 50 caliber bullet round at 4,500 psi. The benefit of such a capability is readily evident in the form of increased safety for all users of high pressure fuel and oxygen storage who must operate in an environment exposing them to ballistic and other impact hazards. The decreased risk of injury due to fragmentation, explosion and "sympathetic detonation" of highly pressurized storage cylinders is of great potential benefit for the military across the board.

Filament Winding

HyPerComp

The 4 axis multiple spindle machines allows HEI to custom design wrapping patterns for custom COPVs and fiber or resin evaluations. The filament winding machines can utilize wet or prepreg filament winding processes to wrap COPVs. HEI specializes in custom designed patterns to design and build ultra-light COPVs.

People

About

Founded in 1996 by its President, James Patterson, HyPerComp Engineering Inc. (HEI) specializes in the design, analysis, development, testing, manufacture, and certification of filament wound high pressure composite vessels for diverse applications. Innovation is HEI’s core competence, rooted in our heritage on the cutting edge of the space composites industry and distinguishes us as a leader in breakthrough technologies for lighter, stronger and safer pressure vessels and structures. In addition, our customers benefit from HEI’s close relationships with and ready access to leading COPV industry participants ranging from material and machinery suppliers, independent testing agencies, regulatory agencies, to aerospace and automotive OEM’s and their supply chains. The result for the client is a flexible, experienced and innovative source for even the most challenging requirements.

HEI’s innovative expertise is underscored by our recent role in the development of next-generation storage vessel solutions for both the automotive and military aerospace industries. Not only did HEI successfully supply the first “proof of concept” extreme high pressure gaseous and cryogenic compressed Hydrogen automotive COPVs to the world’s leading automotive OEMs in the early adaption of Hydrogen, but also supplied the US military with ultralight fuel storage COPVs for Unmanned Aerial Vehicles enabling record setting flight endurance capabilities.

Further COPV innovations include ballistic damage tolerance, non-catastrophic failure capabilities, cryogenic storage and extreme light weight technologies. The applications range from commercial and military aerospace, offshore oil and gas, medical, breathing apparatus and recreational to industrial gas infrastructure. Ultra high pressures, exceptional cycle life and extreme operating environments typify many of our clients’ technical challenges. We also optimize Type 2, Type 3 and Type 4 designs for maximum manufacturing economy. HEI is strategically networked with the world’s leading COPV material suppliers and is intimately familiar in the properties and applications of most commercially available composite fibers and resins, as well as liners.

HEI not only offers these technical services, but is open to strategic partnering, creative joint development, technology licensing and toll manufacturing as options for our clients.

HEI’s innovative expertise is underscored by our recent role in the development of next-generation storage vessel solutions for both the automotive and military aerospace industries. Not only did HEI successfully supply the first “proof of concept” extreme high pressure gaseous and cryogenic compressed Hydrogen automotive COPVs to the world’s leading automotive OEMs in the early adaption of Hydrogen, but also supplied the US military with ultralight fuel storage COPVs for Unmanned Aerial Vehicles enabling record setting flight endurance capabilities.

Further COPV innovations include ballistic damage tolerance, non-catastrophic failure capabilities, cryogenic storage and extreme light weight technologies. The applications range from commercial and military aerospace, offshore oil and gas, medical, breathing apparatus and recreational to industrial gas infrastructure. Ultra high pressures, exceptional cycle life and extreme operating environments typify many of our clients’ technical challenges. We also optimize Type 2, Type 3 and Type 4 designs for maximum manufacturing economy. HEI is strategically networked with the world’s leading COPV material suppliers and is intimately familiar in the properties and applications of most commercially available composite fibers and resins, as well as liners.

HEI not only offers these technical services, but is open to strategic partnering, creative joint development, technology licensing and toll manufacturing as options for our clients.

Add Attachment

Share

Recent Chats

Share via email

Future: handle WhatsApp here

Future: handle LinkedIn here

Future: handle Twitter here

SUBMENU HERE

Share via Chat

Copy Link