_300.webp)

Composite armor

Aerospace, vehicles, naval vessels, personal protection

Design, engineering and manufacturing of armor and survivability solutions

For over 30 years. In 2023 we transitioned from TenCate Advanced Armor to Integris Composites

Tier 1 aerospace supplier for Bell, Boeing, Airbus, and Embraer, and others

Focused on increasing protection and survivability through Accelerated Innovation

Deep data, modeling, simulation and rapid prototyping

INTEGRIS COMPOSITES

For over three decades, we have provided lifesaving armor protection to the world’s elite military and law enforcement units. Our offerings include ballistic plates, vehicle armor kits, and ballistic and blast protection for personal protection, land vehicles, aerospace, and marine applications.

Vienna, Virginia, United States

Aerospace, Defense & Security, Maritime

+1 704 458 7796

People

News

Other

About

People

News

INTEGRIS COMPOSITES JOINS PARIS AIR SHOW AT USA PAVILION

Integris Composites Inc., the U.S. arm of the global leader in armor protection for the world’s elite military, law enforcement and security agencies, will join the 55th Paris Air Show at the USA Partnership Pavilion in Hall 3, Stand A109.

When the expo resumes Monday, June 16, a team from Integris Composites will be among 2,500 exhibitors from 48 countries presenting to as many as 300,000 visitors. Although Integris operates a facility 300 miles away in France, its U.S. delegation will emphasize domestic capabilities, its U.S. base and U.S. government credentials for innovating aircraft armor and survivability solutions in today’s evolving combat environment.

The Integris team will participate alongside a cluster of Ohio companies assembled by the French American Chamber of Commerce Ohio. Integris, which operates its technical center and major U.S. manufacturing hub at its Licking County facility, accepted FACC Ohio’s invitation as a gold sponsor to help promote the state’s aviation capabilities at the air show.

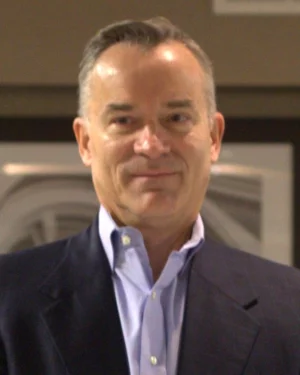

“We are a global company with a deep pool of design and engineering talent on both sides of the Atlantic, providing aerospace survivability solutions worldwide,” said Andrew Bonham, president. “But U.S. military specifiers and defense contractors need to source domestically. We’re here at Le Bourget to reinforce Integris’ U.S. roots and highlight what we’re calling ‘Accelerated Innovation” — our ability to generate targeted solutions faster than anyone else in the armor business. We’re proud of our achievements and of our growing partnerships with prestigious multinational defense contractors.”

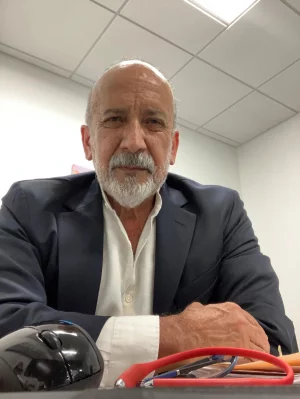

In just over three decades, Integris Composites has earned tier-one supplier credentials with original equipment manufacturers like Airbus Helicopters and Embraer and prime defense contractors globally and in the United States, ”added David Cordova, chief commercial officer. Recent awards include contracts to armor the U.S. Army’s Future Long Range Assault Aircraft, Boeing’s MH-139 Grey Wolf and QinetiQ for the C-130J.

The Licking County facility in Hebron houses the U.S. technical design and engineering center and manufacturing operations. The company also operates a vehicle design center in Santa Barbara, California, and maintains corporate headquarters in Tysons Corner, Virginia, near the U.S. capital.

Formerly known as TenCate Advanced Armor until 2023, Integris Composites continues to lead in advanced materials and rapid prototyping for defense and sustainability.

When the expo resumes Monday, June 16, a team from Integris Composites will be among 2,500 exhibitors from 48 countries presenting to as many as 300,000 visitors. Although Integris operates a facility 300 miles away in France, its U.S. delegation will emphasize domestic capabilities, its U.S. base and U.S. government credentials for innovating aircraft armor and survivability solutions in today’s evolving combat environment.

The Integris team will participate alongside a cluster of Ohio companies assembled by the French American Chamber of Commerce Ohio. Integris, which operates its technical center and major U.S. manufacturing hub at its Licking County facility, accepted FACC Ohio’s invitation as a gold sponsor to help promote the state’s aviation capabilities at the air show.

“We are a global company with a deep pool of design and engineering talent on both sides of the Atlantic, providing aerospace survivability solutions worldwide,” said Andrew Bonham, president. “But U.S. military specifiers and defense contractors need to source domestically. We’re here at Le Bourget to reinforce Integris’ U.S. roots and highlight what we’re calling ‘Accelerated Innovation” — our ability to generate targeted solutions faster than anyone else in the armor business. We’re proud of our achievements and of our growing partnerships with prestigious multinational defense contractors.”

In just over three decades, Integris Composites has earned tier-one supplier credentials with original equipment manufacturers like Airbus Helicopters and Embraer and prime defense contractors globally and in the United States, ”added David Cordova, chief commercial officer. Recent awards include contracts to armor the U.S. Army’s Future Long Range Assault Aircraft, Boeing’s MH-139 Grey Wolf and QinetiQ for the C-130J.

The Licking County facility in Hebron houses the U.S. technical design and engineering center and manufacturing operations. The company also operates a vehicle design center in Santa Barbara, California, and maintains corporate headquarters in Tysons Corner, Virginia, near the U.S. capital.

Formerly known as TenCate Advanced Armor until 2023, Integris Composites continues to lead in advanced materials and rapid prototyping for defense and sustainability.

16 Jun 2025

Integris Composites has been selected by Bell Textron Inc., a Textron Inc. company, as a supplier of armor systems for the Future Long Range Assault Aircraft (FLRAA).

“We are grateful to be selected by Bell,” said Andrew Bonham, president of Integris Composites, Inc., the U.S. component of Integris Composites ─ which last year became the new name for TenCate Advanced Armour, continuing a quarter-century legacy as a resource for form, safety, dependability and survivability.

“All of us at Integris are extremely proud to be part of the team behind this innovative rotorcraft that is ushering in what will become the U.S. Army’s new long-range assault aircraft ensuring our nation’s warfighters have the decisive edge in any theater where they are operating,” Bonham continued.

“We are pleased to include Integris Composites on the team for its protective armor capabilities for the FLRAA,” said Ryan Ehinger, senior vice president and program director for FLRAA, Bell. “Bell and the FLRAA team are committed to delivering not just more speed and range to our soldiers, but more survivability and reliability as well,” Ehinger stated.

A Storied Legacy

“Integris becomes a part of the latest chapter in the storied legacy of utility aircraft, a lineage that traces its roots back to the iconic Vietnam-era ‘Huey’ (UH-1 Iroquois) and the present-day UH-60 Black Hawk, which has faithfully served as the Army’s Utility Tactical Transport Aircraft (UTTAS) since 1979,” said David Cordova, chief commercial officer for Integris, Inc.

“FLRAA is a marvel of engineering that promises to redefine the boundaries of speed, agility, operational versatility/survivability,” Cordova observed.

Advanced Armor from Integris on Land, Water and in the Air

“This is the latest armor contract for Integris in the airborne segment,” added Bonham. “It’s an exceptional achievement for both the Integris organization as well as commercial partners, such as the team at QinetiQ Group plc.”

Cordova said Integris is supporting several other aerospace companies. “We provide armored kits such as the H-125, MH-139 as well as the C-130J this last one, in partnership with QinetiQ. But Integris is also providing high-performance, lightweight, fit-for-purpose composite military armor on the ground and in the water as well as in the air,” said Cordova.

Photo Credit: Bell

Press Release: Link

“All of us at Integris are extremely proud to be part of the team behind this innovative rotorcraft that is ushering in what will become the U.S. Army’s new long-range assault aircraft ensuring our nation’s warfighters have the decisive edge in any theater where they are operating,” Bonham continued.

“We are pleased to include Integris Composites on the team for its protective armor capabilities for the FLRAA,” said Ryan Ehinger, senior vice president and program director for FLRAA, Bell. “Bell and the FLRAA team are committed to delivering not just more speed and range to our soldiers, but more survivability and reliability as well,” Ehinger stated.

A Storied Legacy

“Integris becomes a part of the latest chapter in the storied legacy of utility aircraft, a lineage that traces its roots back to the iconic Vietnam-era ‘Huey’ (UH-1 Iroquois) and the present-day UH-60 Black Hawk, which has faithfully served as the Army’s Utility Tactical Transport Aircraft (UTTAS) since 1979,” said David Cordova, chief commercial officer for Integris, Inc.

“FLRAA is a marvel of engineering that promises to redefine the boundaries of speed, agility, operational versatility/survivability,” Cordova observed.

Advanced Armor from Integris on Land, Water and in the Air

“This is the latest armor contract for Integris in the airborne segment,” added Bonham. “It’s an exceptional achievement for both the Integris organization as well as commercial partners, such as the team at QinetiQ Group plc.”

Cordova said Integris is supporting several other aerospace companies. “We provide armored kits such as the H-125, MH-139 as well as the C-130J this last one, in partnership with QinetiQ. But Integris is also providing high-performance, lightweight, fit-for-purpose composite military armor on the ground and in the water as well as in the air,” said Cordova.

Photo Credit: Bell

Press Release: Link

16 Jun 2025

Integris Enhances Aerospace Capabilities

In the aerospace industry, ballistic protection is paramount for ensuring the safety and operational integrity of aircraft, particularly in military and high-risk environments. This protective measure involves the strategic placement of armor within the aircraft to shield critical components and personnel from ballistic threats.

Ballistic protection is primarily implemented in the cockpit walls, engine compartments, cabin and other vulnerable areas of the aircraft. In the cockpit, armor is essential to safeguard pilots against potential attacks, allowing them to maintain control of the aircraft even under fire. Engine compartments are also fortified to prevent catastrophic failures that could result from ballistic impacts.

Johann Basselin, Key Account Manager at Integris, sheds light on the company’s journey and capabilities in this niche market.

The journey of Integris in aerospace began with a pivotal opportunity with Eurocopter (now Airbus Helicopters). The company needed armor for their new NH90 helicopter, marking the start of Integris’ aerospace division.

“We were selected and started our business with OEM as a Tier 1 supplier. This initial project laid the foundation for Integris to expand its aerospace capabilities and establish a strong presence in the industry,” Basselin recalls.

Integris faced numerous challenges as they adapted to the new aerospace contract requirements. The company had to familiarize itself with a plethora of new documents and standards unique to the aerospace industry. To ensure success, Integris collaborated with a specialized aerospace company in the Netherlands, DC, which provided invaluable support in areas such as integrated logistics support and documentation.

“We needed the support of a specific aerospace company, which assisted us in the beginning. This collaboration was crucial in meeting the high standards required for aerospace projects”, states Mathieu Vilaltella – Aerospace Project Manager.

Since then, Integris has leveraged its past experiences to streamline processes for new projects, This strategy has proven effective, allowing the company to efficiently manage and deliver on aerospace contracts.

The aerospace segment now constitutes a significant portion of Integris’ business.

Integris has provided ballistic protection for various aircraft, starting with the H135 from Airbus Helicopters. The company’s portfolio has expanded to include the NH90, H145, H225M (Super Puma), H175, and potentially the H160 in the future. Additionally, Integris has supplied ballistic protection for Leonardo Helicopters’ platforms such as the AW159, AW101, and AW169, as well as fixed-wing aircraft like the Super Tucano and the KC-390 from Embraer. The company also engages in retrofit business, updating older aircraft with new ballistic protection as needed.

An interesting facet of Integris’ aerospace work is their involvement in civil commercial aircraft protection. Following the events of September 2001, all commercial aircraft must have armor on the cockpit wall. Integris has been selected for the A350, and most A350 aircraft flying worldwide are equipped with their armor.

Basselin expresses optimism for future opportunities, stating, “We are convinced that based on our experience and track record, we will be able to further expand our footprint in the aerospace business segment and supporting customers with new qualifications on different platforms “

Integris’ aerospace capabilities are a testament to their ability to adapt and thrive in a complex and demanding defence industry. Their expertise and strategic collaborations have positioned them as a reliable partner in the aerospace sector, continuously pushing the boundaries of what is possible in ballistic protection for aircraft.

Ballistic protection is primarily implemented in the cockpit walls, engine compartments, cabin and other vulnerable areas of the aircraft. In the cockpit, armor is essential to safeguard pilots against potential attacks, allowing them to maintain control of the aircraft even under fire. Engine compartments are also fortified to prevent catastrophic failures that could result from ballistic impacts.

Johann Basselin, Key Account Manager at Integris, sheds light on the company’s journey and capabilities in this niche market.

The journey of Integris in aerospace began with a pivotal opportunity with Eurocopter (now Airbus Helicopters). The company needed armor for their new NH90 helicopter, marking the start of Integris’ aerospace division.

“We were selected and started our business with OEM as a Tier 1 supplier. This initial project laid the foundation for Integris to expand its aerospace capabilities and establish a strong presence in the industry,” Basselin recalls.

Integris faced numerous challenges as they adapted to the new aerospace contract requirements. The company had to familiarize itself with a plethora of new documents and standards unique to the aerospace industry. To ensure success, Integris collaborated with a specialized aerospace company in the Netherlands, DC, which provided invaluable support in areas such as integrated logistics support and documentation.

“We needed the support of a specific aerospace company, which assisted us in the beginning. This collaboration was crucial in meeting the high standards required for aerospace projects”, states Mathieu Vilaltella – Aerospace Project Manager.

Since then, Integris has leveraged its past experiences to streamline processes for new projects, This strategy has proven effective, allowing the company to efficiently manage and deliver on aerospace contracts.

The aerospace segment now constitutes a significant portion of Integris’ business.

Integris has provided ballistic protection for various aircraft, starting with the H135 from Airbus Helicopters. The company’s portfolio has expanded to include the NH90, H145, H225M (Super Puma), H175, and potentially the H160 in the future. Additionally, Integris has supplied ballistic protection for Leonardo Helicopters’ platforms such as the AW159, AW101, and AW169, as well as fixed-wing aircraft like the Super Tucano and the KC-390 from Embraer. The company also engages in retrofit business, updating older aircraft with new ballistic protection as needed.

An interesting facet of Integris’ aerospace work is their involvement in civil commercial aircraft protection. Following the events of September 2001, all commercial aircraft must have armor on the cockpit wall. Integris has been selected for the A350, and most A350 aircraft flying worldwide are equipped with their armor.

Basselin expresses optimism for future opportunities, stating, “We are convinced that based on our experience and track record, we will be able to further expand our footprint in the aerospace business segment and supporting customers with new qualifications on different platforms “

Integris’ aerospace capabilities are a testament to their ability to adapt and thrive in a complex and demanding defence industry. Their expertise and strategic collaborations have positioned them as a reliable partner in the aerospace sector, continuously pushing the boundaries of what is possible in ballistic protection for aircraft.

13 Jun 2025

Boeing’s recent delivery of the first MH-139A Grey Wolf production aircraft to the U.S. Air Force is a milestone for both Boeing and Integris Composites, Inc

For Integris Composites, this delivery marks the realization of a strategic goal established in 2015 — to be a credentialed Tier One supplier to aerospace manufacturers.

“This event signifies the culmination of a nine-year journey,” said Andrew Bonham, president of Integris Composites, Inc. “Our European business was previously established as a global aerospace supplier. In 2015, our U.S. management team set the goal of attaining Tier One supplier status with OEM aviation companies and U.S. Department of Defense decision-makers. By 2017, we achieved AS9100 certification, a vital credential for aerospace companies, ensuring compliance with stringent quality and safety standards,” Bonham explained.

“Then in 2018, Boeing awarded us a contract to develop and engineer the MH-139A armor system. Development, design, and qualification work with Boeing, and Research, Development, Test and Evaluation aircraft with the Air Force followed. Now, thanks to a follow-on contract with Boeing, we are manufacturing the armor kits for the production aircraft,” explained David Cordova, chief commercial officer.

Integris Composites, Inc. has become a credentialed Tier One supplier to aerospace original equipment manufacturers (OEMs) and prime defense contractors. “Besides Boeing, we have contracts with Bell Flight, Airbus, Velocity Systems, QinetiQ, Battelle Memorial Institute, Mack Defense, American Rheinmetall Vehicles, and the Air Force Institute of Technology,” said Cordova.

“Achieving Tier One aerospace supplier status enhances our already strong business and solidifies our reputation as a trusted provider of ballistic armor systems for vehicles, aviation, and personnel. These systems offer critical protection for personnel operating in hostile environments such as warfighters, tactical security personnel and elite law enforcement units,” Cordova continued.

“Integris Composites produces the most advanced strength-to-weight-ratio in armor for military organizations throughout the world,” Cordova continued. Last year Integris Composites became the new name for TenCate Advanced Armour, a global company founded in Europe 30 years ago this year.

Photo Credits: Department of Defence

(The appearance of U.S. Department of Defense (DoD) visual information does not imply or constitute DoD endorsement.)

“This event signifies the culmination of a nine-year journey,” said Andrew Bonham, president of Integris Composites, Inc. “Our European business was previously established as a global aerospace supplier. In 2015, our U.S. management team set the goal of attaining Tier One supplier status with OEM aviation companies and U.S. Department of Defense decision-makers. By 2017, we achieved AS9100 certification, a vital credential for aerospace companies, ensuring compliance with stringent quality and safety standards,” Bonham explained.

“Then in 2018, Boeing awarded us a contract to develop and engineer the MH-139A armor system. Development, design, and qualification work with Boeing, and Research, Development, Test and Evaluation aircraft with the Air Force followed. Now, thanks to a follow-on contract with Boeing, we are manufacturing the armor kits for the production aircraft,” explained David Cordova, chief commercial officer.

Integris Composites, Inc. has become a credentialed Tier One supplier to aerospace original equipment manufacturers (OEMs) and prime defense contractors. “Besides Boeing, we have contracts with Bell Flight, Airbus, Velocity Systems, QinetiQ, Battelle Memorial Institute, Mack Defense, American Rheinmetall Vehicles, and the Air Force Institute of Technology,” said Cordova.

“Achieving Tier One aerospace supplier status enhances our already strong business and solidifies our reputation as a trusted provider of ballistic armor systems for vehicles, aviation, and personnel. These systems offer critical protection for personnel operating in hostile environments such as warfighters, tactical security personnel and elite law enforcement units,” Cordova continued.

“Integris Composites produces the most advanced strength-to-weight-ratio in armor for military organizations throughout the world,” Cordova continued. Last year Integris Composites became the new name for TenCate Advanced Armour, a global company founded in Europe 30 years ago this year.

Photo Credits: Department of Defence

(The appearance of U.S. Department of Defense (DoD) visual information does not imply or constitute DoD endorsement.)

13 Jun 2025

About

We handle the design, engineering, and manufacturing of armor and survivability solutions tailored to specific needs. As a Tier 1 aerospace supplier, we collaborate with leading OEMs, including Bell, Boeing, Airbus, and Embraer. We have armored a large number of vehicles in the US and other NATO and allied countries. In maritime armor, we recently announced a contract to supply ballistic protection systems for the Royal Navy’s Type 45 destroyer.

In the face of a changing environment in combat we have developed an approach we call Accelerated Innovation. Our focus is on continuing to increase protection levels, using composite materials, and being able to come up with high performing solutions rapidly through the use of modeling, simulation and rapid prototyping that rely on our extensive database of both ballistic and blast solutions.

In the face of a changing environment in combat we have developed an approach we call Accelerated Innovation. Our focus is on continuing to increase protection levels, using composite materials, and being able to come up with high performing solutions rapidly through the use of modeling, simulation and rapid prototyping that rely on our extensive database of both ballistic and blast solutions.

Add Attachment

Share

Recent Chats

Share via email

Future: handle WhatsApp here

Future: handle LinkedIn here

Future: handle Twitter here

SUBMENU HERE

Share via Chat

Copy Link