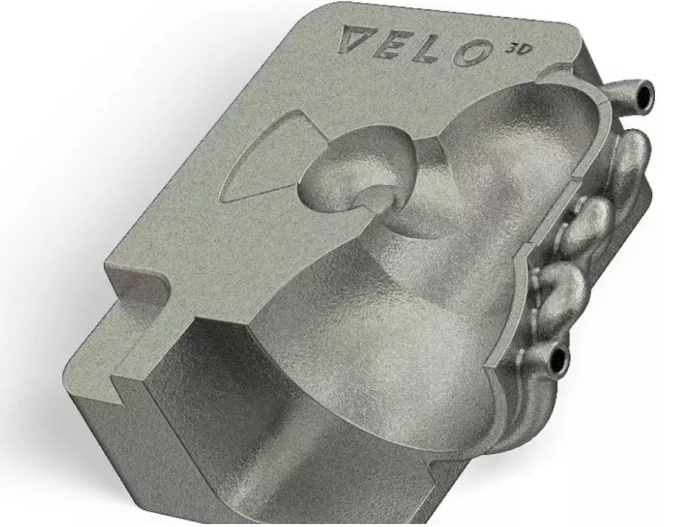

Tooling Inserts High Pressure Die Cast (HPDC) Inserts, Sprue Bushings, and Injection Molding Dies

Tooling Inserts High Pressure Die Cast (HPDC) Inserts, Sprue Bushings, and Injection Molding Dies

The Velo3D fully integrated manufacturing (AM) solution enables improved cooling channel designs that can increase the lifetime of HPDC inserts, sprue bushings, injection molding dies and other types of tooling.

Description

More Products & Services

Products & Services

Sapphire & Sapphire 1MZ Printers

Velo3D

Velo3D provides a revolutionary metal end-to-end additive manufacturing solution enabling designers to build parts they need without design or quality compromises. The Velo3D intelligent solution is not just a printer, it is a highly integrated production system driven by our underlying SupportFree manufacturing process. The solution includes our Flow intelligent print preparation software, your choice of a Sapphire printer, and our Assure quality monitoring and control software.

The Sapphire family of printers are next generation laser powder bed fusion metal AM printers capable of printing complex geometries including low angle prints down to zero degrees, high aspect ratio structures up to 3000:1, large inner diameters up to 100 mm, and support free free-floating parts previously thought impossible.

The Sapphire family of printers are next generation laser powder bed fusion metal AM printers capable of printing complex geometries including low angle prints down to zero degrees, high aspect ratio structures up to 3000:1, large inner diameters up to 100 mm, and support free free-floating parts previously thought impossible.

Velo3D’s Fully Integrated Metal AM Solution

Velo3D

At Velo3D, we enable innovators to create the future by providing a fully integrated metal 3D printing solution for mission-critical parts. Our advanced solution helps innovators build the complex parts they need without compromising design or quality, empowering the visionaries of today to build the technologies of tomorrow.

In this whitepaper, we explore the benefits of the Velo3D fully integrated solution, including the unprecedented design freedom, agility, quality assurance, and efficiency enabled by our family of state-of-the-art metal 3D printers.

In this whitepaper, we explore the benefits of the Velo3D fully integrated solution, including the unprecedented design freedom, agility, quality assurance, and efficiency enabled by our family of state-of-the-art metal 3D printers.

Velo3D’s newest Metal AM printer - Sapphire XC

Velo3D

Sapphire was just the beginning! Watch as Benny Buller, Velo3D CEO and Founder, and Greg Brown, Vice President, Process Engineering, discuss the additive manufacturing innovations enabled by the new Sapphire XC metal 3D printer.

Discover how this larger “extra capacity” model is helping to solve complex engineering challenges, including the printing of bigger and cheaper parts, and how Velo3D is helping advance the AM industry beyond its previous limits.

Discover how this larger “extra capacity” model is helping to solve complex engineering challenges, including the printing of bigger and cheaper parts, and how Velo3D is helping advance the AM industry beyond its previous limits.

Whitepapers & E-Books

Velo3D

Learn more about Velo3D’s advanced metal additive manufacturing solution with our expansive library of whitepapers and e-books.

Velo3D – Design Freedom In Action

Velo3D

True design freedom means letting you focus on parts optimized for performance, not manufacturability, resulting in high quality metal parts. Watch this video and learn how Velo3D’s solution gives engineers unprecedented design freedom with real-world examples of parts that feature complex geometries including thin pins and walls, circular holes, zero-degree (horizontal) overhangs, and more.

People

Description

The Velo3D fully integrated manufacturing (AM) solution enables improved cooling channel designs that can increase the lifetime of HPDC inserts, sprue bushings, injection molding dies and other types of tooling.

Share

Recent Chats

Share via email

Future: handle WhatsApp here

Future: handle LinkedIn here

Future: handle Twitter here

SUBMENU HERE

Share via Chat

Copy Link