CNC Turning

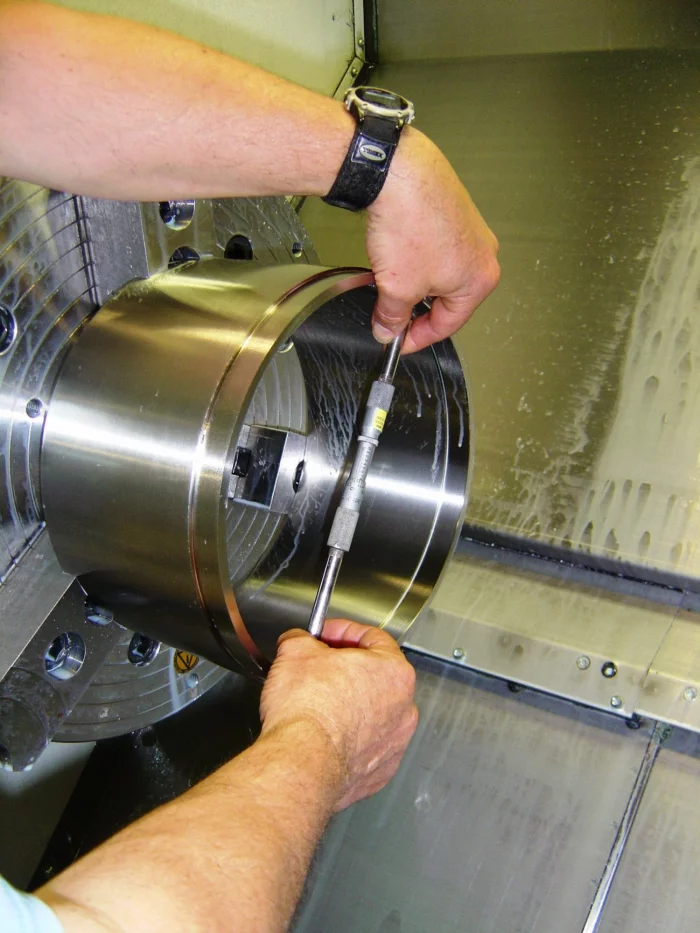

While a milling machine could create cylindrical shapes when necessary, our CNC Turning services work faster and more efficiently to complete the process. Any metal pieces that require lathing services can be turned on the spindle. The cutting tool attached to the turret moves in and out to remove the excess metal according to the design.

Description

More Products & Services

Products & Services

Double Disc Grinding

Hygrade Precision Technologies, LLC

A core capability of our flat grinding services, double-sided precision grinding efficiently grinds both sides of an object simultaneously and maintains the tight tolerances you expect from Hygrade.

We produce perfect parts to meet our customers’ needs with the quality and timeliness they expect.

We produce perfect parts to meet our customers’ needs with the quality and timeliness they expect.

Blanchard Grinding

Hygrade Precision Technologies, LLC

For metals with diameters up to 42 inches, magnetic or non-magnetic, Blanchard grinding removes the most material on one side than any other process. Fast and effective, this method works well for low and high-volume orders covering significant surface areas.

Named after the Blanchard Machine Company that developed the machine back in the 1900s, this process is an economical choice for large parts and plates. Blanchard grinding creates a recognizable crosshatch pattern while maintaining accuracy and high tolerances.

Named after the Blanchard Machine Company that developed the machine back in the 1900s, this process is an economical choice for large parts and plates. Blanchard grinding creates a recognizable crosshatch pattern while maintaining accuracy and high tolerances.

Nital Etch Inspection

Hygrade Precision Technologies, LLC

Nital etch, or surface temper etch, inspection further promises accuracy and dependability after production. The process tests over-tempering, re-tempering, re-hardening, discontinuous carburization or a decarburized surface layer. The etch burns or hardens areas depending on their different potential problems.

Nital solution used for testing is a combination of nitric acid and alcohol that etches steel. Because grinding can cause heat, this process ensures the product is cooled and still strong as required after tempering.

Nital solution used for testing is a combination of nitric acid and alcohol that etches steel. Because grinding can cause heat, this process ensures the product is cooled and still strong as required after tempering.

Single Side Lapping

Hygrade Precision Technologies, LLC

Flat lapping guarantees a smoother, flatter surface, and Hygrade can help you achieve tolerances out to the millionths!

Our highly skilled machinists achieve your tight requirements within a transparent timeline. With our single-sided lapping services, we process parts up to 17” in diameter and routinely achieve tolerances in the millionths. Flatness can be held to helium light bands.

Lapping works best with batch pieces, creating a uniformly matte or mirrored surface depending on your specifications. This is a low-stress process for the metal because it proceeds slowly enough to minimize thermal distortion.

Our highly skilled machinists achieve your tight requirements within a transparent timeline. With our single-sided lapping services, we process parts up to 17” in diameter and routinely achieve tolerances in the millionths. Flatness can be held to helium light bands.

Lapping works best with batch pieces, creating a uniformly matte or mirrored surface depending on your specifications. This is a low-stress process for the metal because it proceeds slowly enough to minimize thermal distortion.

CNC ID/OD Grinding

Hygrade Precision Technologies, LLC

Inner diameter (ID) and outer diameter (OD) grinding make up a large portion of CNC machining for the finishing of cylindrical features in high tolerance applications.

Hygrade’s combination of class leading machines and skilled machinists allow us to reach the tightest tolerances that traditional machining cannot achieve. We serve the aerospace, defense, medical, automotive and other industries with their high requirements achieved by skilled operators who have been with us for decades.

Hygrades ID/OD grinding capabilities include various sizes and finishes through hydrostatic way repeatability and rigidity.

Hygrade’s combination of class leading machines and skilled machinists allow us to reach the tightest tolerances that traditional machining cannot achieve. We serve the aerospace, defense, medical, automotive and other industries with their high requirements achieved by skilled operators who have been with us for decades.

Hygrades ID/OD grinding capabilities include various sizes and finishes through hydrostatic way repeatability and rigidity.

Double Side Lapping

Hygrade Precision Technologies, LLC

Using a similar process to single-sided lapping, double-sided lapping machines typically process more delicate and thin pieces but have the capability to work with thicker pieces as well.

The lapping compound helps achieve tight tolerances as well as polishing without compromising the strength of the part through heat or shaping.

This technology processes multiple pieces at once, achieving parallelism and the same strict tolerances across all the parts. At Hygrade, we have the capacity to handle both small batches and large orders for millions of parts due to our machine redundancy and the efficient, effective use of our experienced operators.

The lapping compound helps achieve tight tolerances as well as polishing without compromising the strength of the part through heat or shaping.

This technology processes multiple pieces at once, achieving parallelism and the same strict tolerances across all the parts. At Hygrade, we have the capacity to handle both small batches and large orders for millions of parts due to our machine redundancy and the efficient, effective use of our experienced operators.

People

Description

While a milling machine could create cylindrical shapes when necessary, our CNC Turning services work faster and more efficiently to complete the process. Any metal pieces that require lathing services can be turned on the spindle. The cutting tool attached to the turret moves in and out to remove the excess metal according to the design.

CNC milling and turning often work together on the same part: it may start on the turn shaft and later have specific milling required to complete the product.

We save you even more time by including grinding processes on site to start and finish the project on schedule.

With Hygrade’s experienced machinists, your product will be completed on schedule. We’ll send you a shipping notification before you have the chance to ask for one.

CNC milling and turning often work together on the same part: it may start on the turn shaft and later have specific milling required to complete the product.

We save you even more time by including grinding processes on site to start and finish the project on schedule.

With Hygrade’s experienced machinists, your product will be completed on schedule. We’ll send you a shipping notification before you have the chance to ask for one.

Share

Recent Chats

Share via email

Future: handle WhatsApp here

Future: handle LinkedIn here

Future: handle Twitter here

SUBMENU HERE

Share via Chat

Copy Link