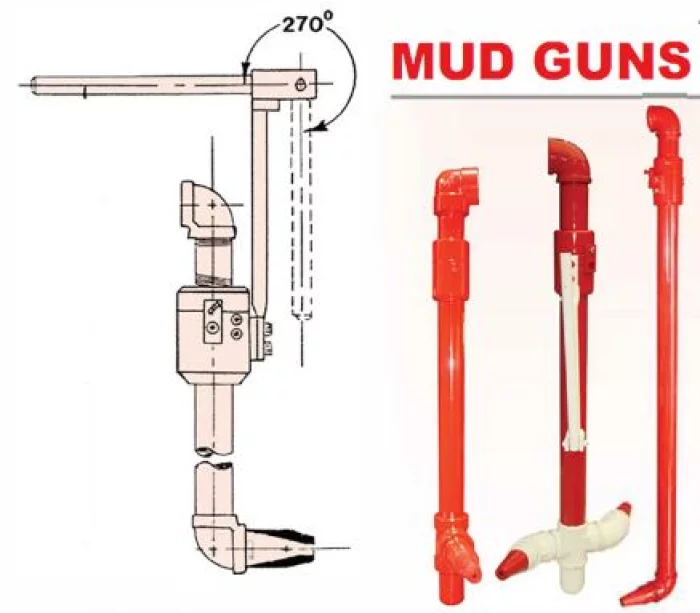

Mud Guns, Swivels and Eductors

The Hoffmann Ventures low pressure 3" mud guns and Eductors are designed for submerged service in mud pits to offer maximum blending and agitation of settled solids.

Description

More Products & Services

Products & Services

Bulk (Big) Bag Hopper

Hoffmann Ventures, LLC

The bulk powders are then drawn from the bulk bag and hopper into the incorporated mixing

eductor via low pressure suction generated inside the eductor mixing chamber, allowing for rapid and

complete mixing and blending with prewetting capabilities.

The optional Dual Suction Shearing Hopper allows for an additional free standing hopper to

dump traditional 50 lb. and 100 lb. material sacks manually into the fluid stream for mixing.

ALL CAN BE CUSTOMIZED

eductor via low pressure suction generated inside the eductor mixing chamber, allowing for rapid and

complete mixing and blending with prewetting capabilities.

The optional Dual Suction Shearing Hopper allows for an additional free standing hopper to

dump traditional 50 lb. and 100 lb. material sacks manually into the fluid stream for mixing.

ALL CAN BE CUSTOMIZED

Shear Mixer, Mud Hopper

Hoffmann Ventures, LLC

The Shearing Hopper operates using no moving mechanical parts and solely the pressure energy

of a liquid feed. That pressurized liquid feed is forced into a high velocity stream through a specialized

nozzle to create a low-pressure vacuum zone inside a mixing chamber. This low-pressure mixing

chamber features a butterfly valve allowing the utilization of the vacuum to draw dry powders into the

prewetting chamber prior to combining the prewetted material with the motive flow in the mixing

chamber. Preventing fisheyes and clogging and allowing rapid mixing of specialized products such as

polymers.

of a liquid feed. That pressurized liquid feed is forced into a high velocity stream through a specialized

nozzle to create a low-pressure vacuum zone inside a mixing chamber. This low-pressure mixing

chamber features a butterfly valve allowing the utilization of the vacuum to draw dry powders into the

prewetting chamber prior to combining the prewetted material with the motive flow in the mixing

chamber. Preventing fisheyes and clogging and allowing rapid mixing of specialized products such as

polymers.

Shear Mixer Spare parts

Hoffmann Ventures, LLC

Shear Mixer Spare parts

Solids Control, Shale Shaker wear items

Hoffmann Ventures, LLC

Hoffmann Ventures offers aftermarket and genuine OEM parts for most shakers, mud cleaners, centrifuges and screening equipment

Caustic Mixer

Hoffmann Ventures, LLC

The Caustic Mixer is constructed in all stainless steel for long lasting durability and exceptional

corrosion resistance and features a low profile/light weight design. It utilizes a low horsepower/low

consumption air motor and mixing impeller to fully mix and blend batches. The incorporated skid base

features built in forklift tine slots for ease of placement and mobility.

The Caustic Mixer is designed with human safety in mind first. It features a worktable with a

locking, self-supporting safety hatch for bag dumping. The hatch raises and locks to stay open while

dumping, then simply pushing up on the hatch releases the lock to lower the hatch door again. The

hatch and dumping box is fully enclosed facing the worker and utilizes a sloped design to carry dumped

powders out the open bottom to prevent splash back and other hazards.

corrosion resistance and features a low profile/light weight design. It utilizes a low horsepower/low

consumption air motor and mixing impeller to fully mix and blend batches. The incorporated skid base

features built in forklift tine slots for ease of placement and mobility.

The Caustic Mixer is designed with human safety in mind first. It features a worktable with a

locking, self-supporting safety hatch for bag dumping. The hatch raises and locks to stay open while

dumping, then simply pushing up on the hatch releases the lock to lower the hatch door again. The

hatch and dumping box is fully enclosed facing the worker and utilizes a sloped design to carry dumped

powders out the open bottom to prevent splash back and other hazards.

Drilling and Production Chemical Products

Hoffmann Ventures, LLC

Providing “The Chemical Solution”

At Hoffmann Ventures a team of professionals work to create a “Chemical Solution” to solve your particular problem that is unique and proactive. We work from the perspective that all problems can be solved by placing the right complimentary set of solutions to work rather than segmented temporary solutions.

Production Treating Chemical Products & Services

Decades of development support the products offered by Hoffmann Ventures The production chemical team at Hoffmann Ventures are constantly considering the most recent chemical developments in its oilfield production chemical product line. New technologies are emerging that can positively improve the overall scope of production treating programs. Our technical staff are expertly trained and ex-perienced in the task of formulating the right solution to many of the everyday as well as unique problems encountered in the production of oil & gas onshore and offshore.

At Hoffmann Ventures a team of professionals work to create a “Chemical Solution” to solve your particular problem that is unique and proactive. We work from the perspective that all problems can be solved by placing the right complimentary set of solutions to work rather than segmented temporary solutions.

Production Treating Chemical Products & Services

Decades of development support the products offered by Hoffmann Ventures The production chemical team at Hoffmann Ventures are constantly considering the most recent chemical developments in its oilfield production chemical product line. New technologies are emerging that can positively improve the overall scope of production treating programs. Our technical staff are expertly trained and ex-perienced in the task of formulating the right solution to many of the everyday as well as unique problems encountered in the production of oil & gas onshore and offshore.

Description

The Hoffmann Ventures low pressure 3" mud guns and Eductors are designed for submerged service in mud pits to offer maximum blending and agitation of settled solids. It is available in two models: single head and double head with 5/8" nozzle. The swivel joints are provided with lubricating fittings, ball bearings and easily replaceable seals. The handle design facilitates a 360 degree rotation. Efficient mixing requires 65 to 75 feet of

pumping head at the mud gun. Hoffmann Ventures mud guns are supplied with Poly urethane nozzles for a longer life.

pumping head at the mud gun. Hoffmann Ventures mud guns are supplied with Poly urethane nozzles for a longer life.

Share

Recent Chats

Share via email

Future: handle WhatsApp here

Future: handle LinkedIn here

Future: handle Twitter here

SUBMENU HERE

Share via Chat

Copy Link