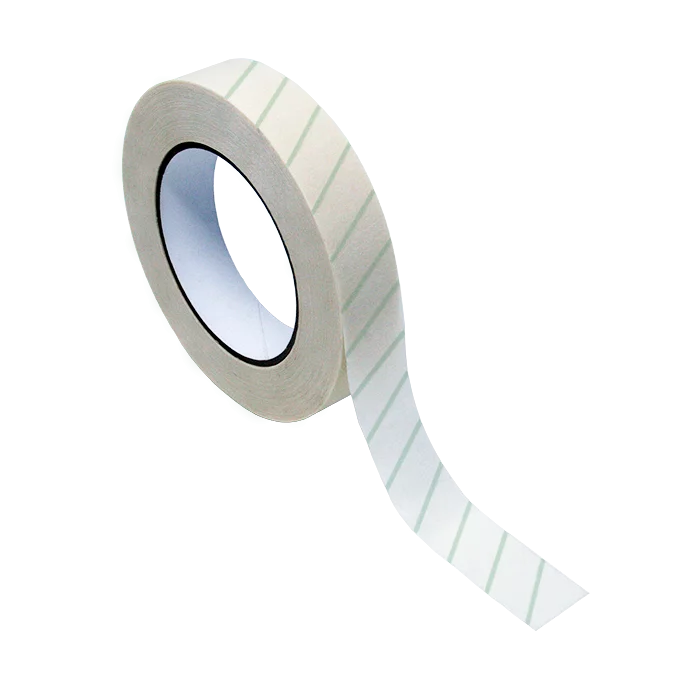

Verline™ Autoclave Indicator Tape

Distinct Color Change

From Green to Black

Distinguish between processed and unprocessed sterilization packages

Strong crepe-embossed, latex-free tape

For use in securing wrapped surgical trays before, during, and after sterilization

Verline™ Autoclave Indicator Tape

Propper Verline™ Indicator Tape secures packages during steam sterilization and confirms exposure to the sterilant after processing.

Description

More Products & Services

Products & Services

Steri-Wrap® II

Propper Manufacturing Co., Inc.

Steri-Wrap® cellulose-based sterilization wrap is available in three grades to keep your packages safe and secure during the sterilization process. Steri-Wrap® II is a a medium-weight wrap, featuring excellent drapeability, making it ideal for delicate or hard to wrap items. All grades of Steri-Wrap® are virtually lint-free with tightly anchored fibers and are reversible with excellent liquid repellency. Steri-Wrap® can be used in steam or ethylene oxide sterilization, making it a versatile and reliable choice for your sterilization needs.

Use Steri-Wrap® Cellulose Based Sterilization Wrap to sterilize packages in steam or EO.

Use Steri-Wrap® Cellulose Based Sterilization Wrap to sterilize packages in steam or EO.

Steam-Dot™ Process Indicators For Steam Sterilization

Propper Manufacturing Co., Inc.

Steam-Dot™ Process Indicators for Steam Sterilization provide a reliable, and visually evident confirmation of successful steam sterilization, ensuring peace of mind for healthcare professionals worldwide.

These self-adhesive process indicators offer exceptional convenience and ease of use. Simply affix one indicator to each package. Upon completion of the steam sterilization cycle, observe the color change of the indicator. Steam-Dot™ indicators clearly differentiate between processed and unprocessed packages, providing at-a-glance assurance of sterilization efficacy.

These self-adhesive process indicators offer exceptional convenience and ease of use. Simply affix one indicator to each package. Upon completion of the steam sterilization cycle, observe the color change of the indicator. Steam-Dot™ indicators clearly differentiate between processed and unprocessed packages, providing at-a-glance assurance of sterilization efficacy.

Chex-All® Sterilization Pouches

Propper Manufacturing Co., Inc.

Chex-All® Heat Seal Sterilization Pouches provide a sterile barrier, and feature easy-to-read pre-printed indicators (both inside and outside the pouch). Heat-Sealing pouches provide the convenience of custom sizing to meet the individual needs of your instruments.

Chex-All® pouches are for use in steam and ethylene oxide, eliminating the need for two sets of pouches.

Chex-All® pouches are validated for double pouch packaging.

Heat Seal Sterilization Pouches allow you to choose the exact length your need

Easy-to-read chemical indicator changes from yellow to black in steam

Easy-to-read chemical indicator changes from red to green in EO

Made of 2.5 mm plastic and 73-74 gram

Triple sealed paper/plastic film provides excellent sterility protection

Chex-All® pouches are for use in steam and ethylene oxide, eliminating the need for two sets of pouches.

Chex-All® pouches are validated for double pouch packaging.

Heat Seal Sterilization Pouches allow you to choose the exact length your need

Easy-to-read chemical indicator changes from yellow to black in steam

Easy-to-read chemical indicator changes from red to green in EO

Made of 2.5 mm plastic and 73-74 gram

Triple sealed paper/plastic film provides excellent sterility protection

Twindicator® Perforated Steam Sterilization Indicators

Propper Manufacturing Co., Inc.

Twindicator® Perforated Steam Indicators are Type 4 chemical indicators. They monitor steam sterilization cycles at 250°F (121°C) and 273°F (134°C). Place Twindicator® strips inside of pouches, trays, or other packages. The ink on the strip turns from off-white to black when exposed to the steam sterilization process.

WD chex™ Washer-Disinfector Monitor

Propper Manufacturing Co., Inc.

WD chex™ Washer-Disinfector Monitor is an essential part of your cleaning efficacy protocol. Its results correlate to the cleaning challenge of surgical instruments.

WD chex is a reliable, repeatable, and consistent method for evaluating automated instrument washers.

The indicator can:

Confirm washer-disinfector function throughout the tank

Detect common reasons for wash-disinfector failure:

Clogged spray arms

Spray arm orientation

Overloaded instrument trays

Detergent presence

Monitor time for successful soil removal

Monitor temperature for ideal enzymatic performance

WD chex™ Washer-Disinfector Monitor is a key part of your cleaning assurance program. The test soil presents the cleaning equipment with a physical challenge, such as the cleaning efficacy test described in ISO 15883-5.

Use it with the reusable OK-Sonic™/ WD chex™ Monitor Holder

WD chex is a reliable, repeatable, and consistent method for evaluating automated instrument washers.

The indicator can:

Confirm washer-disinfector function throughout the tank

Detect common reasons for wash-disinfector failure:

Clogged spray arms

Spray arm orientation

Overloaded instrument trays

Detergent presence

Monitor time for successful soil removal

Monitor temperature for ideal enzymatic performance

WD chex™ Washer-Disinfector Monitor is a key part of your cleaning assurance program. The test soil presents the cleaning equipment with a physical challenge, such as the cleaning efficacy test described in ISO 15883-5.

Use it with the reusable OK-Sonic™/ WD chex™ Monitor Holder

OK-Sonic™ Ultrasonic Bath Monitor

Propper Manufacturing Co., Inc.

OK-Sonic™ Ultrasonic Bath Monitor has two blue protein-based soil spots on a plastic substrate. The soil spots do not contain any natural blood and have no risk of contaminating the cleaning chamber and its contents. The soil mixture contains organic proteins, lipids, and polysaccharides that mimic the soil. Which are typically present on medical instruments and devices after use with patients and in laboratory settings.

Ultrasonic baths use high-frequency pressure ultrasonic (sound) waves to induce cavitation bubbles. The cavitation bubbles implode and agitate the liquid, removing any soil.

When OK-Sonic™ is placed in an ultrasonic cleaner, the blue soil dissolves slowly by cavitation, removing soil in the cleaning bath. The presence of detergent and the pre-soaking phase expedite this process. When exposed to sufficient cleaning cycle parameters, the soil spots wash off entirely from the substrate. Use OK-Sonic™ with the OK-Sonic™/ WD chex™ Monitor Holder, which acts as a process challenge device. The Holder covers the indicator soil on one side of the monitor while fully exposing the other soil spot. The covered soil simulates challenging conditions for cleaning. This includes instrument hinges, cavities, and instruments layered on top of one another in the bath. The open soil area simulates areas fully exposed to cleaning cycle parameters inside an ultrasonic cleaner basket.

OK-Sonic™ Ultrasonic Bath Monitor is a vital part of your cleaning assurance program. OK-Sonic™ is suitable for hospital and industrial ultrasonic cleaners.

Use it with the reusable OK-Sonic™/ WD chex™ Monitor Holder

The Holder acts as a process challenge device, which covers the indicator soil on one side of the monitor while leaving the other soil spot fully exposed.

Ultrasonic baths use high-frequency pressure ultrasonic (sound) waves to induce cavitation bubbles. The cavitation bubbles implode and agitate the liquid, removing any soil.

When OK-Sonic™ is placed in an ultrasonic cleaner, the blue soil dissolves slowly by cavitation, removing soil in the cleaning bath. The presence of detergent and the pre-soaking phase expedite this process. When exposed to sufficient cleaning cycle parameters, the soil spots wash off entirely from the substrate. Use OK-Sonic™ with the OK-Sonic™/ WD chex™ Monitor Holder, which acts as a process challenge device. The Holder covers the indicator soil on one side of the monitor while fully exposing the other soil spot. The covered soil simulates challenging conditions for cleaning. This includes instrument hinges, cavities, and instruments layered on top of one another in the bath. The open soil area simulates areas fully exposed to cleaning cycle parameters inside an ultrasonic cleaner basket.

OK-Sonic™ Ultrasonic Bath Monitor is a vital part of your cleaning assurance program. OK-Sonic™ is suitable for hospital and industrial ultrasonic cleaners.

Use it with the reusable OK-Sonic™/ WD chex™ Monitor Holder

The Holder acts as a process challenge device, which covers the indicator soil on one side of the monitor while leaving the other soil spot fully exposed.

Steam Chex™ Blue Autoclave Indicator Tape

Propper Manufacturing Co., Inc.

Steam Chex™ Lead-Free Autoclave Steam Indicator Tape is pressure-sensitive sterilization and used to distinguish between processed and unprocessed items.

The lead-free indicator ink placed in green stripes that turn dark brown/black after exposure to a steam sterilization cycle.

Steam Chex™ Tape’s strong adhesive and even coating allow for even dispensing and easy application. Specifically formulated universal adhesive provides secure bonding with fabric and non-woven wraps, paper, metal, and glass, yet provides easy removal without traces of residue.

AAMI/ISO 11140-1 Type 1 Compliant Process Indicator

Not Made with Natural Rubber Latex

Lead-Free Beige Autoclave Indicator Tape: Verline™

Provides a means of identifying steam-sterilized packs while ensuring their security during sterilization

The lead-free indicator ink placed in green stripes that turn dark brown/black after exposure to a steam sterilization cycle.

Steam Chex™ Tape’s strong adhesive and even coating allow for even dispensing and easy application. Specifically formulated universal adhesive provides secure bonding with fabric and non-woven wraps, paper, metal, and glass, yet provides easy removal without traces of residue.

AAMI/ISO 11140-1 Type 1 Compliant Process Indicator

Not Made with Natural Rubber Latex

Lead-Free Beige Autoclave Indicator Tape: Verline™

Provides a means of identifying steam-sterilized packs while ensuring their security during sterilization

Steri-Wrap® I

Propper Manufacturing Co., Inc.

Steri-Wrap® I is a light-to-medium weight, virtually lint-free sterilization wrap with tightly anchored fibers. It is reversible and features excellent liquid repellency, making it ideal for general hospital use in steam or ethylene oxide sterilization cycles. Suitable for linen packs, basin sets, instruments, and instrument trays

Features and benefits:

Effective microbial barrier

High-level protection against fluids and particles

Highly permeable for efficient sterilization

Reversible for ease of use

Virtually lint-free to eliminate contamination risk

Excellent liquid repellency to protect sterile contents

Compatible with steam and ethylene oxide sterilization cycles

Applications for Steri-Wrap® I Sterilization Wrap

General hospital use

Surgical instrument sterilization

Medical device sterilization

Tray wrapping

Bassinette wrapping

Other sterile packaging applications

Steri-Wrap® I is a trusted choice in hospitals and other healthcare settings around the world. It is known for its high quality, reliability, and performance. You can have added confidence that Steri-Wrap® I is also backed by Propper’s commitment to customer satisfaction and support.

Steri-Wrap® is cellulose-based sterilization wrap available in three grades for keeping packages safe and secure during the sterilization process.

Steri-Wrap® can be used in steam or ethylene oxide sterilization.

Features and benefits:

Effective microbial barrier

High-level protection against fluids and particles

Highly permeable for efficient sterilization

Reversible for ease of use

Virtually lint-free to eliminate contamination risk

Excellent liquid repellency to protect sterile contents

Compatible with steam and ethylene oxide sterilization cycles

Applications for Steri-Wrap® I Sterilization Wrap

General hospital use

Surgical instrument sterilization

Medical device sterilization

Tray wrapping

Bassinette wrapping

Other sterile packaging applications

Steri-Wrap® I is a trusted choice in hospitals and other healthcare settings around the world. It is known for its high quality, reliability, and performance. You can have added confidence that Steri-Wrap® I is also backed by Propper’s commitment to customer satisfaction and support.

Steri-Wrap® is cellulose-based sterilization wrap available in three grades for keeping packages safe and secure during the sterilization process.

Steri-Wrap® can be used in steam or ethylene oxide sterilization.

Steri-Wrap® Unite™ 60 SMS Sterilization Wrap

Propper Manufacturing Co., Inc.

Steri-Wrap® Unite™ 60 SMS Sterilization Wrap comprises two sheets of SMS bonded together for convenient simultaneous enveloping of one or a collection of medical devices. Following standard healthcare practices conforming to ISO 11607-1:2019 and EN 868-2:2017.31505400. The wraps are made of polypropylene with blue or green pigment and anti-static treatment. Steri-Wrap® Unite™ SMS Sterilization Wrap 60 contains instruments during steam, ethylene oxide, and vaporized hydrogen peroxide sterilization and maintains sterility after processing.

The sterilization wrap allows effective sterilant penetration and maintains the sterility of reusable devices during handling and storage. The two-color sheet allows for easier visualization of damage, tears, or punctures and can be used to differentiate between loaner and facility-owned trays.

This SMS sterilization wrap maintains sterility for 365 days.

Maximum package weight in Steam and Ethylene Oxide 13lbs.

Maximum package weight in vH2O2: 9-10 lbs depending on equipment.

Industry standard for sterile processing teams around the world

Tear-, flame-, lint- and abrasion-resistant

Pre-vacuum & Gravity steam sterilant penetration

Ethylene Oxide (EO) sterilant penetration and residuals

Vaporized Hydrogen Peroxide sterilant penetration

Maintenance of package integrity (MPI) to meet FDA requirements

Instructions for Use that meet FDA guidelines

Class 1 flammability rating

Low linting

The sterilization wrap allows effective sterilant penetration and maintains the sterility of reusable devices during handling and storage. The two-color sheet allows for easier visualization of damage, tears, or punctures and can be used to differentiate between loaner and facility-owned trays.

This SMS sterilization wrap maintains sterility for 365 days.

Maximum package weight in Steam and Ethylene Oxide 13lbs.

Maximum package weight in vH2O2: 9-10 lbs depending on equipment.

Industry standard for sterile processing teams around the world

Tear-, flame-, lint- and abrasion-resistant

Pre-vacuum & Gravity steam sterilant penetration

Ethylene Oxide (EO) sterilant penetration and residuals

Vaporized Hydrogen Peroxide sterilant penetration

Maintenance of package integrity (MPI) to meet FDA requirements

Instructions for Use that meet FDA guidelines

Class 1 flammability rating

Low linting

ProExpose™ Protein Detection Test

Propper Manufacturing Co., Inc.

ProExpose™ Protein Detection Test confirms that your instruments are clean. ProExpose™ tests for the presence of proteins to verify the effectiveness of manual or mechanical cleaning (ultrasonic or washer-disinfector) before high-level disinfection or sterilization.

Utilizing sterile water, swab a difficult-to-clean portion of an instrument, then place the swab into the test tube containing the solution. If protein is present solution will turn blue. ProExpose™ is semi-quantitative. The more protein present in the sample the darker the blue color change will be.

ProExpose™ detects protein to a sensitivity of 1μg of protein, ensuring the safety of your instruments and patients.

Conform to all relevant ANSI/AAMI standards for cleaning verification tests AAMI/ST79, ISO 15883, HTM2030

• ProExpose Short Swab kit: general testing of surfaces.

• ProExpose Long Swab kit: for testing inside channels of rigid and flexible endoscopes and other potentially contaminated lumen instruments.

ProExpose™ Protein Detection Test may also be of use to reduce the risk of food safety incidents by testing potentially contaminated surfaces for residual proteins.

Utilizing sterile water, swab a difficult-to-clean portion of an instrument, then place the swab into the test tube containing the solution. If protein is present solution will turn blue. ProExpose™ is semi-quantitative. The more protein present in the sample the darker the blue color change will be.

ProExpose™ detects protein to a sensitivity of 1μg of protein, ensuring the safety of your instruments and patients.

Conform to all relevant ANSI/AAMI standards for cleaning verification tests AAMI/ST79, ISO 15883, HTM2030

• ProExpose Short Swab kit: general testing of surfaces.

• ProExpose Long Swab kit: for testing inside channels of rigid and flexible endoscopes and other potentially contaminated lumen instruments.

ProExpose™ Protein Detection Test may also be of use to reduce the risk of food safety incidents by testing potentially contaminated surfaces for residual proteins.

BI-O.K.™ Self-Contained Ethylene Oxide Biological Indicator Vials

Propper Manufacturing Co., Inc.

BI-O.K.™ Ethylene Oxide Biological Indicator vials are easy to use. Simply place one vial in each sterilization load in a pack or test pack. Upon completion of the EO cycle, activate the vial by crushing the glass ampoule with the provided vial activator. This releases the spores into the nutrient media, initiating the incubation process.

After incubation at 37°C for 48 hours, the media’s color change indicates whether the cycle was effective. If the media remains red, indicating the absence of spore growth, the sterilization process was successful. However, if the media turns yellow, it signifies spore growth, indicating a sterilization cycle failure.

BI-O.K.™ vials adhere to stringent quality standards and are rigorously tested to ensure their reliability in detecting even the most challenging microorganisms.

After incubation at 37°C for 48 hours, the media’s color change indicates whether the cycle was effective. If the media remains red, indicating the absence of spore growth, the sterilization process was successful. However, if the media turns yellow, it signifies spore growth, indicating a sterilization cycle failure.

BI-O.K.™ vials adhere to stringent quality standards and are rigorously tested to ensure their reliability in detecting even the most challenging microorganisms.

Gas-Chex® EO Indicator Strips

Propper Manufacturing Co., Inc.

Gas-Chex® EO Indicator Strips are an internal pack monitor that provides an immediate visual method of monitoring all warm and cool cycles of 100% ethylene oxide (EO, EtO) and EO/HCFC (ethylene oxide / hydrochlorofluorocarbon) gas mixture sterilization processes. They are independent monitors of critical parameters for the following sterilization cycles: (temperature, gas concentration, humidity, and time)

37°C 736 mg/L ≥35% 3 hours

37°C 759 mg/L ≥35% 3 hours

38°C 736 mg/L 40-80% 4.5 hours

38°C 759 mg/L 40-80% 4.5 hours

55°C 736 mg/L ≥35% 1 hour

55°C 759 mg/L ≥35% 1 hour

55°C 600 mg/L 60% 4 hours

37°C 736 mg/L ≥35% 3 hours

37°C 759 mg/L ≥35% 3 hours

38°C 736 mg/L 40-80% 4.5 hours

38°C 759 mg/L 40-80% 4.5 hours

55°C 736 mg/L ≥35% 1 hour

55°C 759 mg/L ≥35% 1 hour

55°C 600 mg/L 60% 4 hours

Chex-All® III Instant-Seal Pouches

Propper Manufacturing Co., Inc.

Chex-All III® pouches offer the convenience of self-sealing along with the advantage of pre-printed chemical indicators on the corners of the pouch, covered by a plastic film to provide an added challenge. Chex-All III® Instant-Seal Sterilization Pouches provide breathability while also producing a sterile barrier. Chevron corner seals assure dust-free, aseptic presentation.

Chex-All III® Instant-Seal Sterilization Pouches are for use in steam and ethylene oxide, eliminating the need for two sets of pouches.

Chex-All III® pouches are validated for double pouch packaging.

Self-Sealing Sterilization Pouches feature easy-to-use adhesive along the top of the pouch

Chemical indicator provides a distinct color change from yellow to black in steam

Chemical indicator provides a distinct color change from red to green in EO

Made of 2.5 mm plastic and 73-74 gram paper

Chex-All III® Instant-Seal Sterilization Pouches are for use in steam and ethylene oxide, eliminating the need for two sets of pouches.

Chex-All III® pouches are validated for double pouch packaging.

Self-Sealing Sterilization Pouches feature easy-to-use adhesive along the top of the pouch

Chemical indicator provides a distinct color change from yellow to black in steam

Chemical indicator provides a distinct color change from red to green in EO

Made of 2.5 mm plastic and 73-74 gram paper

Steri-Wrap® III

Propper Manufacturing Co., Inc.

Steri-Wrap® III Sequential Sterilization Wrap is a cellulose-based wrap, that keeps packages safe and secure during the sterilization process. It is a heavy-weight wrap that is suitable for your heaviest instrument packages.

Steri-Wrap® is designed to be virtually link-free with tightly anchored fibers. The wrap is reversible and features excellent liquid repellency.

Steri-Wrap® can be used in steam or ethylene oxide sterilization.

Steri-Wrap® is designed to be virtually link-free with tightly anchored fibers. The wrap is reversible and features excellent liquid repellency.

Steri-Wrap® can be used in steam or ethylene oxide sterilization.

OK® Steam Sterilization Indicators

Propper Manufacturing Co., Inc.

Type 4 Chemical Indicator OK® Steam Sterilization Strips monitor packs at 250°F (121°C) and 273°F (134°C) gravity and vacuum-assisted steam sterilization cycles. OK® Strips are internal pack monitors available in short (4″, 10cm) and long (8″, 20 cm) sizes. Indicator strips are 0.6″/1.5 cm wide.

OK Chemical Indicator Strips confirm that all critical parameters of steam sterilization have been met: time, temperature, and saturation (ANSI/AAMI/ISO 11140-1:2014 ).

OK® Strips feature an instantly recognizable “OK” symbol after exposure to an effective steam sterilization cycle. “K” will turn from off-white/white to dark brown/black color.

The 8″ indicator strip features an indicator dot at the opposing end to extend its reach in a tray or other sterilization packaging.

OK Chemical Indicator Strips confirm that all critical parameters of steam sterilization have been met: time, temperature, and saturation (ANSI/AAMI/ISO 11140-1:2014 ).

OK® Strips feature an instantly recognizable “OK” symbol after exposure to an effective steam sterilization cycle. “K” will turn from off-white/white to dark brown/black color.

The 8″ indicator strip features an indicator dot at the opposing end to extend its reach in a tray or other sterilization packaging.

Steri-Dot® Process Indicators For EO Gas Sterilization

Propper Manufacturing Co., Inc.

Unparalleled Visual Confirmation

Steri-Dot® Ethylene Oxide Self-Adhesive Process Indicators offer a quick and reliable visual confirmation of EO sterilization efficacy. These indicators undergo a distinct color change from red to green when exposed to the appropriate sterilization cycle. This clear visual transition eliminates any ambiguity and provides immediate assurance that your sterilized items are safe for use.

Adherence to Stringent Standards

Steri-Dot® Indicators adhere to the stringent standards of AAMI ST60 and ISO 11140-1, Type 1 Process Indicators. These standards ensure that the indicators provide accurate and reliable representation of the sterilization process.

Enhanced Sterilization Assurance

Beyond visual confirmation, the color change of Steri-Dot® Indicators is contingent upon the presence of adequate humidity. This color change confirms exposure to the sterilant.

Versatile Application and Secure Adhesion

Steri-Dot® Ethylene Oxide Process Indicators adhere firmly to a variety of surfaces, making them suitable for use with a wide range of medical devices and equipment. This versatility ensures that you can effectively monitor the sterilization process regardless of the item being sterilized.

Embrace Peace of Mind with Steri-Dot®

Incorporate Steri-Dot® Ethylene Oxide Self-Adhesive Process Indicators into your workflow and experience the peace of mind that comes with knowing your medical devices and equipment are truly sterile. Order your supply today and safeguard the health of your patients.

Steam-Dot™ Type 1 Self-Adhesive Process Indicators

Provides a fast positive visual check for processed packages sterilized in steam.

Steri-Dot® Ethylene Oxide Self-Adhesive Process Indicators offer a quick and reliable visual confirmation of EO sterilization efficacy. These indicators undergo a distinct color change from red to green when exposed to the appropriate sterilization cycle. This clear visual transition eliminates any ambiguity and provides immediate assurance that your sterilized items are safe for use.

Adherence to Stringent Standards

Steri-Dot® Indicators adhere to the stringent standards of AAMI ST60 and ISO 11140-1, Type 1 Process Indicators. These standards ensure that the indicators provide accurate and reliable representation of the sterilization process.

Enhanced Sterilization Assurance

Beyond visual confirmation, the color change of Steri-Dot® Indicators is contingent upon the presence of adequate humidity. This color change confirms exposure to the sterilant.

Versatile Application and Secure Adhesion

Steri-Dot® Ethylene Oxide Process Indicators adhere firmly to a variety of surfaces, making them suitable for use with a wide range of medical devices and equipment. This versatility ensures that you can effectively monitor the sterilization process regardless of the item being sterilized.

Embrace Peace of Mind with Steri-Dot®

Incorporate Steri-Dot® Ethylene Oxide Self-Adhesive Process Indicators into your workflow and experience the peace of mind that comes with knowing your medical devices and equipment are truly sterile. Order your supply today and safeguard the health of your patients.

Steam-Dot™ Type 1 Self-Adhesive Process Indicators

Provides a fast positive visual check for processed packages sterilized in steam.

Propper Washer-Disinfector Test Soil Kit

Propper Manufacturing Co., Inc.

Propper Washer-Disinfector Test Soil Kit provides an easy way to determine if your washer-disinfector is functioning properly.

Propper Washer-Disinfector Test Soil mimics the most difficult-to-clean microscopic residue and body fluids that occurs naturally during the use of medical instruments, laboratory glassware, and other materials. The test soil presents the cleaning equipment with a physical challenge, such as the cleaning efficacy test described in ISO 15883-5.

Add water using the supplied measuring cup and 7-8 drops of black dye. Apply the paste liberally to the surface to be tested, and allow 30-60 minutes of dry time. Process the soiled test piece using routine washer-disinfector procedures, and inspect for residual soil.

WD chex™ Washer-Disinfector Monitor

To confirm your washer-disinfector’s efficacy with each load.

Propper Washer-Disinfector Test Soil mimics the most difficult-to-clean microscopic residue and body fluids that occurs naturally during the use of medical instruments, laboratory glassware, and other materials. The test soil presents the cleaning equipment with a physical challenge, such as the cleaning efficacy test described in ISO 15883-5.

Add water using the supplied measuring cup and 7-8 drops of black dye. Apply the paste liberally to the surface to be tested, and allow 30-60 minutes of dry time. Process the soiled test piece using routine washer-disinfector procedures, and inspect for residual soil.

WD chex™ Washer-Disinfector Monitor

To confirm your washer-disinfector’s efficacy with each load.

BI-O.K.™ Steam Biological Indicator Vials

Propper Manufacturing Co., Inc.

BI-O.K.™ self-contained biological indicator vials monitor steam sterilization loads. Use biological indicators to release for all steam sterilization loads. Vials are inoculated with Geobacillus stearothermophilus spores to challenge steam sterilization.

Use in a steam test pack during the cycle. After the sterilization cycle activate the media by crushing the glass vial with the vial activator and incubate at 57°C. Exposure to steam triggers a chemical process indicator on the vial to react. A color change in the media indicates spore growth and cycle failure.

Use in a steam test pack during the cycle. After the sterilization cycle activate the media by crushing the glass vial with the vial activator and incubate at 57°C. Exposure to steam triggers a chemical process indicator on the vial to react. A color change in the media indicates spore growth and cycle failure.

Vapor Line® Steam Sterilization Integrator

Propper Manufacturing Co., Inc.

Vapor Line® Steam Chemical Integrator is a premium Type 5 chemical indicator that monitors critical conditions during steam sterilization and correlates with the performance of a BI at 3 time/temperature relationships. This chemical integrator provides added sterilization security with an “overkill period” beyond the spore death curve, ensuring sufficient conditions to eliminate even the most resistant microorganisms.

Vapor Line® Steam Integrator’s wick migrates from FAIL to PASS during sterilization. When you receive a PASS result from the Vapor Line® Type 5 Steam Chemical Integrator, the conditions in the sterilized pack were sufficient to eliminate even the most resistant microorganisms.

Vapor Line® is available with or without an extender. There is a chemical indicator on the end of the extender’s. The indicator ink changes from white to dark brown/black after sterilization.

This chemical integrator is suitable for use in sterilization cycles ranging from 250°F (121°C) to 273°F (134°C). Order Type 5 Vapor Line® Steam Chemical Integrator for reliable monitoring performance and results in your practice or laboratory.

Vapor Line® Steam Integrator’s wick migrates from FAIL to PASS during sterilization. When you receive a PASS result from the Vapor Line® Type 5 Steam Chemical Integrator, the conditions in the sterilized pack were sufficient to eliminate even the most resistant microorganisms.

Vapor Line® is available with or without an extender. There is a chemical indicator on the end of the extender’s. The indicator ink changes from white to dark brown/black after sterilization.

This chemical integrator is suitable for use in sterilization cycles ranging from 250°F (121°C) to 273°F (134°C). Order Type 5 Vapor Line® Steam Chemical Integrator for reliable monitoring performance and results in your practice or laboratory.

Description

Propper Verline™ Beige Autoclave Indicator Tape is a pressure-sensitive sterilization tape used to distinguish between processed and unprocessed items.

Verline™ features lead-free indicator ink, placed in green stripes that turn black after exposure to a steam sterilization cycle.

Verline™ Beige Autoclave Indicator Tape’s strong adhesive and even coating allow for even dispensing and easy application. Specifically formulated universal adhesive provides secure bonding with fabric and non-woven wraps, paper, metal, and glass yet provide easy removal without residue traces.

AAMI/ISO 11140-1 Type 1 Compliant Process Indicator Tape

Not Made with Natural Rubber Latex

Verline™ features lead-free indicator ink, placed in green stripes that turn black after exposure to a steam sterilization cycle.

Verline™ Beige Autoclave Indicator Tape’s strong adhesive and even coating allow for even dispensing and easy application. Specifically formulated universal adhesive provides secure bonding with fabric and non-woven wraps, paper, metal, and glass yet provide easy removal without residue traces.

AAMI/ISO 11140-1 Type 1 Compliant Process Indicator Tape

Not Made with Natural Rubber Latex

Share

Recent Chats

Share via email

Future: handle WhatsApp here

Future: handle LinkedIn here

Future: handle Twitter here

SUBMENU HERE

Share via Chat

Copy Link