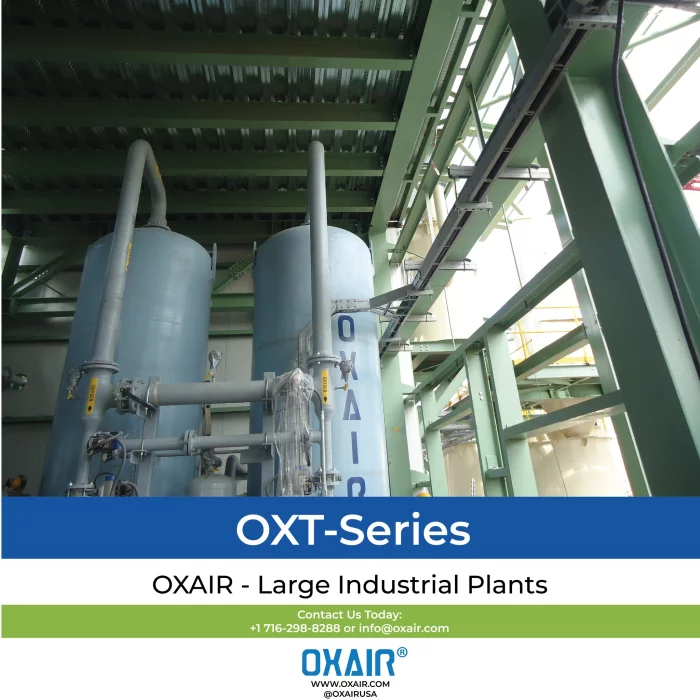

Oxair Large Industrial Plants

OXT-Series - Tonnage Plants

Description

More Products & Services

Products & Services

Oxygen Purifiers

Oxair Ltd.

This secondary stage purification provides a method to scrub the 95% oxygen product produced by zeolite molecular sieves by using a secondary carbon molecular sieve (CMS) to filter out the argon allowing a higher concentration of oxygen at 99% plus purity.

Oxair Cylinder Filling Plant

Oxair Ltd.

Oxair CYLOX-M HP Series Dual purity medical oxygen system.

Medical Packaged Systems

Oxair Ltd.

Oxair OXYMED Systems provide medical grade oxygen with a purity that conforms to the USP93 United States Pharmacopeia, the CE 93/42/CEE European Directive for Medical Devices, and the A.N.M.A.T. Argentina Pharmacopeia.

The OXYMED System is available as a containerized system or as a standalone set of components that can be installed in a ventilated hospital area. Containerized versions available in either 10, 20 or 40 ft. ISO container depending on plant capacity for up to 100 cylinder/day.

Oxair OXYMED turnkey packaged system with individual components are skid-mounted or containerized. All Oxair Standard Oxygen Generators can be packaged using Oxair recommended components or custom-designed to meet customer’s application requirements.

The OXYMED System is available as a containerized system or as a standalone set of components that can be installed in a ventilated hospital area. Containerized versions available in either 10, 20 or 40 ft. ISO container depending on plant capacity for up to 100 cylinder/day.

Oxair OXYMED turnkey packaged system with individual components are skid-mounted or containerized. All Oxair Standard Oxygen Generators can be packaged using Oxair recommended components or custom-designed to meet customer’s application requirements.

Oxygen High Purity Cylinder Filling Systems

Oxair Ltd.

Oxair manufactures a complete line of turn-key Oxygen High Purity Cylinder Filling Systems with filling capacities from 8 to 200 cylinders/day. These cylinders plants operate automatically and are available to fill oxygen cylinders at a minimum pressure of 2200 psig (152 barg).

Complete plants consist of feed air compressor, air treatment package, oxygen generator, oxygen purifier, oxygen compressor, a cylinder filling rack, oxygen analyzer and cylinder evacuation system.

Complete plants consist of feed air compressor, air treatment package, oxygen generator, oxygen purifier, oxygen compressor, a cylinder filling rack, oxygen analyzer and cylinder evacuation system.

Standard Oxygen Generators

Oxair Ltd.

Standard Oxair Oxygen Generators, OX-SERIES produce from 1 Nm3/Hr to 75 Nm3/Hr at purities up to 95%.

Touch screen control provides a user-friendly interface, monitoring the PSA cycle by means of a display of the process and instrumentation diagram, monitors signals from the pressure switches, as well as a shutdown mode for feed air high temperature condition.

Touch screen control provides a user-friendly interface, monitoring the PSA cycle by means of a display of the process and instrumentation diagram, monitors signals from the pressure switches, as well as a shutdown mode for feed air high temperature condition.

Description

* Two Bed High Pressure PSA Systems

These systems are optimized for capital cost. Delivers oxygen at a pressures of 50 psig (3.5 bar).

* Two Bed Low Pressure PSA Systems

Optimized for minimum power consumption. Delivers oxygen at a pressure of up to 15 psig (1 bar).

* Single Bed Low Pressure Vacuum Swing or VSA System

Designed for a combination of low capital and lower power consumption. Delevers oxygen at pressures of up to 15

psig (1 bar).

These systems are optimized for capital cost. Delivers oxygen at a pressures of 50 psig (3.5 bar).

* Two Bed Low Pressure PSA Systems

Optimized for minimum power consumption. Delivers oxygen at a pressure of up to 15 psig (1 bar).

* Single Bed Low Pressure Vacuum Swing or VSA System

Designed for a combination of low capital and lower power consumption. Delevers oxygen at pressures of up to 15

psig (1 bar).

Share

Recent Chats

Share via email

Future: handle WhatsApp here

Future: handle LinkedIn here

Future: handle Twitter here

SUBMENU HERE

Share via Chat

Copy Link