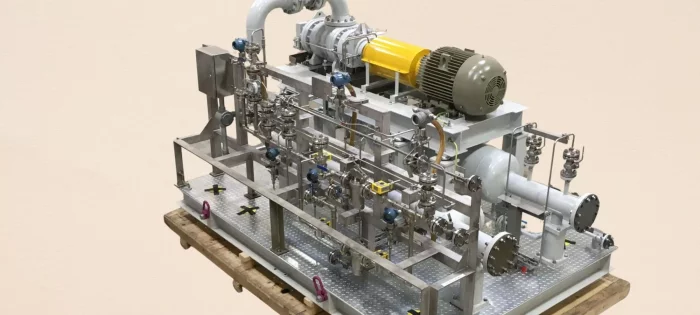

Rotary Compressor, Vacuum Booster and Process Blower packages

API 619 Rotary Lob Compressors

Vacuum Boosters

Process Gas Blowers

Acid Gas Blowers

Hydrogen Compressors

VRU, EFG, FGR

Rotary Compressor, Vacuum Booster and Process Blower packages

World’s leading manufacturer of rotary-lobe compressor, blower and vacuum pump packages for process industries, both onshore and offshore. Our machines are Oil Free to process and API 619 compliant.

API 619

ASME PTC-9

ASME VIII

Description

Description

ROOTS Systems is a leading global manufacturer of oil-free Rotary Lobe Compressors, Process Gas Blowers, and Vacuum Booster packages for process applications. Our company's history dates back to the 1930s.

As a unique feature, our Duragas series is designed to comply with API 619 requirements. We have developed single-stage machines capable of generating pressure rises of up to 4.5 bar (65 psid), with flow capacities ranging from 5 m³/h (3 cfm) to 50,000 m³/h (30,000 cfm), and static pressures up to 365 bar (5,300 psi).

Our packages are custom-designed, manufactured, assembled, and tested in the UK to meet your specific requirements. We have a network of local after-sales partners across the globe. Our equipment complies with relevant standards, including API, ASME, NEMA, AWS, and AGMA, as well as European and international standards (IEC, ATEX) and those of major oil and gas producers.

We specialize in building machines capable of handling a wide range of gases, including toxic, corrosive, flammable, and radioactive gases. Equipment can also be designed for operation in potentially explosive atmospheres. Numerous options are available for sealing configurations (Mechanical Seal and Heremtic Seals) and materials of construction, tailored to your application needs.

Metal components can be manufactured from nodular iron, cast steel, stainless steels, or other corrosion-resistant or exotic alloys (Hasteloy, Duplex, Inconel, Monel, etc.), all in compliance with ASTM and NACE standards.

As a unique feature, our Duragas series is designed to comply with API 619 requirements. We have developed single-stage machines capable of generating pressure rises of up to 4.5 bar (65 psid), with flow capacities ranging from 5 m³/h (3 cfm) to 50,000 m³/h (30,000 cfm), and static pressures up to 365 bar (5,300 psi).

Our packages are custom-designed, manufactured, assembled, and tested in the UK to meet your specific requirements. We have a network of local after-sales partners across the globe. Our equipment complies with relevant standards, including API, ASME, NEMA, AWS, and AGMA, as well as European and international standards (IEC, ATEX) and those of major oil and gas producers.

We specialize in building machines capable of handling a wide range of gases, including toxic, corrosive, flammable, and radioactive gases. Equipment can also be designed for operation in potentially explosive atmospheres. Numerous options are available for sealing configurations (Mechanical Seal and Heremtic Seals) and materials of construction, tailored to your application needs.

Metal components can be manufactured from nodular iron, cast steel, stainless steels, or other corrosion-resistant or exotic alloys (Hasteloy, Duplex, Inconel, Monel, etc.), all in compliance with ASTM and NACE standards.

Share

Recent Chats

Share via email

Future: handle WhatsApp here

Future: handle LinkedIn here

Future: handle Twitter here

SUBMENU HERE

Share via Chat

Copy Link