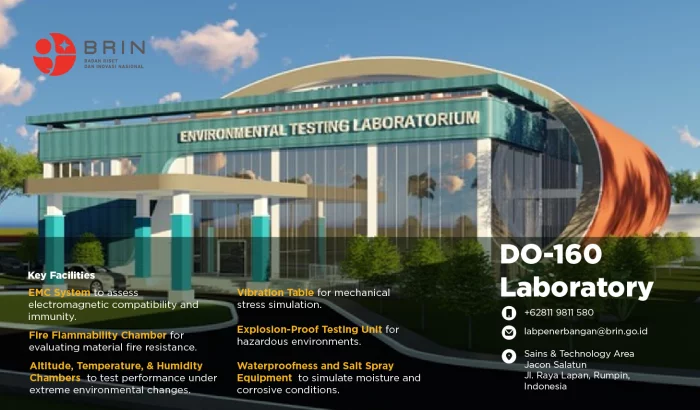

DO-160 Laboratory: Ensuring Reliability in Every Component

Aircraft Component Testing

Certification testing by CASR Part 27 and RTCA DO-160G standards

Non-Aviation Electronics Testing

Compliance testing for devices based on standards from Indonesia’s Regulations

Certified Testing. Safer Skies. Stronger Innovation.

DO-160 Laboratory: Ensuring Reliability in Every Component

When precision and safety matter, DO-160 Laboratory delivers. Operated by BRIN, this facility supports the aviation and electronics industry through internationally recognized testing services—paving the way for innovation ready to fly.

EMC System :

Evaluates device performance in electromagnetic environments to ensure immunity and non-interference

Fire Flammability Test :

Measures fire resistance of materials and aircraft components.

Explosion-Proofness :

Tests equipment safety in flammable atmospheres

Vibration Testing :

Simulates real-world vibration to assess structural durability.

Altitude, Temperature, and Humidity Test :

Examines performance across environmental extremes.

Waterproofness Testing :

Determines resistance to condensation and water spray.

Salt Spray Testing :

Assesses corrosion resistance in saline or coastal conditions.

Description

More Products & Services

Products & Services

Nanotechnology-Based Antifouling Coating

National Research and Innovation Agency/BRIN

Next-generation antifouling coating : environmentally friendly, durable, and functional

Designed with ecological safety in mind, this nanotechnology-based antifouling coating delivers long-lasting protection against marine biofouling. It effectively prevents barnacle and algae buildup without releasing toxic substances. Its antifouling strategy integrates nanotechnology with rare earth elements, specifically cerium oxide, to reduce ecological impact while maintaining high-performance, long-term defence for submerged structures. This technology is designed for active tropical waters and offers long-term protection and potential for multifunctional marine applications.

Designed with ecological safety in mind, this nanotechnology-based antifouling coating delivers long-lasting protection against marine biofouling. It effectively prevents barnacle and algae buildup without releasing toxic substances. Its antifouling strategy integrates nanotechnology with rare earth elements, specifically cerium oxide, to reduce ecological impact while maintaining high-performance, long-term defence for submerged structures. This technology is designed for active tropical waters and offers long-term protection and potential for multifunctional marine applications.

Bullet-Resistant Steel Based on Lateritic Nickel Ore

National Research and Innovation Agency/BRIN

Bullet-Resistant Steel Based on Lateritic Nickel Ore is an innovative material developed from limonitic laterite nickel ore. Designed specifically for ballistic application, this material combines exceptional hardness (~650 HB) with outstanding ductility (31.3% elongation). A rare mechanical pairing in conventional protective steels.

Through an efficient production chain, Nickel Pig Iron (NPI) processing, steelmaking, and hot forming without special heat treatment, this material achieves high performance with low nickel content (≤1.8%), rivaling the performance of high-nickel ballistic steels.

Through an efficient production chain, Nickel Pig Iron (NPI) processing, steelmaking, and hot forming without special heat treatment, this material achieves high performance with low nickel content (≤1.8%), rivaling the performance of high-nickel ballistic steels.

Hydrodynamics Laboratory: Precision in Every Wave

National Research and Innovation Agency/BRIN

BRIN offers a comprehensive range of hydrodynamic services that support the entire process of marine research and testing. The modeling service includes designing and fabricating ship models, propellers, and floating structures under static and dynamic conditions. In the survey area, BRIN conducts marine environmental studies and performs at-sea measurements of ship performance. The laboratory provides facilities for testing to carry out resistance, propulsion, seakeeping, maneuvering, cavitation, and open-water tests. Simulation and numerical analysis services are also available to support design validation and performance optimization through computational methods. BRIN also offers specialized training programs in hydrodynamic technologies and marine engineering to strengthen human resource capacity in the maritime sector.

Aerodynamics, Aeroelasticity & Acoustics Laboratory: Precision in Every Flow

National Research and Innovation Agency/BRIN

The Aerodynamics, Aeroelasticity, and Aeroacoustics Laboratory (LA3) is a leading national facility dedicated to cutting-edge research and testing in aerodynamics, aeroelasticity, and aeroacoustics. Operated under the highest international standards, LA3 provides critical support for experimental and computational studies in fluid mechanics, aircraft performance, structural dynamics, and noise analysis.

The facility is equipped with advanced instrumentation and flow diagnostics, enabling researchers and engineers to conduct detailed investigations into various applications—from full-scale aircraft components to civil infrastructure such as bridges and buildings. LA3 is vital in advancing Indonesia’s aerospace capabilities while supporting non-aerospace sectors with versatile and accredited testing services.

The facility is equipped with advanced instrumentation and flow diagnostics, enabling researchers and engineers to conduct detailed investigations into various applications—from full-scale aircraft components to civil infrastructure such as bridges and buildings. LA3 is vital in advancing Indonesia’s aerospace capabilities while supporting non-aerospace sectors with versatile and accredited testing services.

Innovative Design of a Multi-Purpose Decommissioning and Salvage Vessel (MDSV)

National Research and Innovation Agency/BRIN

The MDSV is a purpose-built vessel integrating the functions of a tugboat, heavy-lift barge, and service platform into a single, versatile unit. Engineered for post-operational offshore platform decommissioning, it also performs maritime salvage operations, including lifting, structural repair, refloating, and navigational clearance. This compact and flexible platform offers an economical solution to the growing demand for offshore decommissioning, particularly in regions with ageing infrastructure.

The design was validated at BRIN’s Hydrodynamics laboratory for resistance, manoeuvrability, and LA3 (Aerodynamics, Aeroelasticity, and Aeroacoustics Laboratory) for the superstructure’s aerodynamic evaluation.

Key technologies—dynamic positioning, automatic ballast control, and an ROV with a diamond wire cutter (cutting capacity up to Ø1.07 m)—enable safe, precise operations in diverse water depths.

The design was validated at BRIN’s Hydrodynamics laboratory for resistance, manoeuvrability, and LA3 (Aerodynamics, Aeroelasticity, and Aeroacoustics Laboratory) for the superstructure’s aerodynamic evaluation.

Key technologies—dynamic positioning, automatic ballast control, and an ROV with a diamond wire cutter (cutting capacity up to Ø1.07 m)—enable safe, precise operations in diverse water depths.

Description

As part of BRIN’s national testing infrastructure, the DO-160 Laboratory provides comprehensive testing services to ensure electronic systems’ safety, reliability, and compliance—particularly in the aviation sector. Designed to meet international standards, the lab supports certification processes and innovation-driven research.

Focusing on environmental, mechanical, and electromagnetic testing, the DO-160 Laboratory is equipped to evaluate a wide range of components, from avionics systems to commercial electronics. With facilities meeting RTCA DO-160G and CASR Part 27 standards, it is a critical facility for aircraft component certification and quality assurance.

Focusing on environmental, mechanical, and electromagnetic testing, the DO-160 Laboratory is equipped to evaluate a wide range of components, from avionics systems to commercial electronics. With facilities meeting RTCA DO-160G and CASR Part 27 standards, it is a critical facility for aircraft component certification and quality assurance.

Share

Recent Chats

Share via email

Future: handle WhatsApp here

Future: handle LinkedIn here

Future: handle Twitter here

SUBMENU HERE

Share via Chat

Copy Link