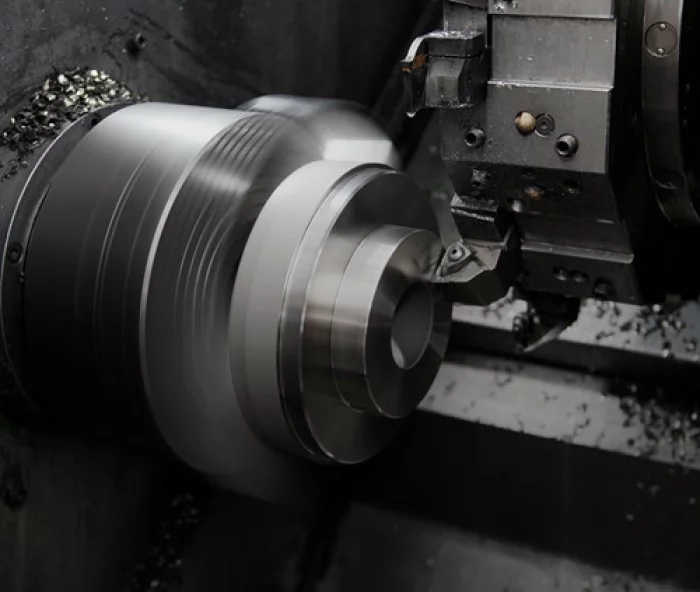

Turning

Burke Aerospace is a trusted partner for Turning of critical parts for the aerospace and industrial gas turbine industries. Burke Aerospace has turning capabilities up to 25’’ diameter components to support our strategic partners.

Description

More Products & Services

Products & Services

Conventional Ram / Sinker EDM

Burke Aerospace

EDM allows intricate shapes and contours to be machined into all types of conductive metal products. Burke Aerospace continues to make substantial investments in the latest EDM technology to meet our customers strictest quality requirements and a competitive price.

Our combination of design and in-house electrode manufacturing provide flexible capabilities to generate new and re-dressed electrodes in support of our customer’s needs.

State-of-the-art power supply technology.

Unprecedented control over the performance of the cut.

CMM and non-contact vision inspection systems.

Our combination of design and in-house electrode manufacturing provide flexible capabilities to generate new and re-dressed electrodes in support of our customer’s needs.

State-of-the-art power supply technology.

Unprecedented control over the performance of the cut.

CMM and non-contact vision inspection systems.

5-Axis Milling

Burke Aerospace

Burke Aerospace has over 30 years of machining expertise and is a leader in the manufacturing of super alloy components. Burke Aerospace invests in the latest 5-Axis equipment available to bring the best processing techniques and reliability to our customers.

More than 20 CNC machining centers including full 5-axis and 3+2 capabilities

Working envelopes up to 50" for mills

More than 20 CNC machining centers including full 5-axis and 3+2 capabilities

Working envelopes up to 50" for mills

Airflow Testing

Burke Aerospace

Burke Aerospace’s airflow equipment is NADCAP certified, calibrated and inspected using NIST qualified standards in accordance with ANSI/NCSL Z540-3 and OEM approved.

All sonic nozzles are accurate to <.1% of entire range.

Burke Aerospace has multiple HABCO AF1000 airflow benches with a full complement of sonic nozzles installed.

High Speed Hole

Burke Aerospace

High Speed Hole Electrical Discharge Machining is a unique way to produce precise, accurate holes in conductive materials regardless of their shape or hardness rapidly and cost effectively. This is accomplished by utilizing the process of eroding material via an electrical spark jumping across the gap between the rotating electrode and the work piece. This eroding of material is done while dielectric fluid is flushed through the hollow electrode at high-pressure to both cool the work piece and remove the eroded material. In addition to round holes, this process allows us to create diffusor shapes around the holes which improves the cooling effectiveness of turbine engine components.

Wire EDM

Burke Aerospace

Burke Aerospace is NADCAP approved for Wire EDM processes. Common part families include ring segmenting, case splitting and complex contouring requiring tight tolerancing. Burke Aerospace has two of the largest Wire EDM machines available to accommodate some of the largest rings and components in the Aerospace market.

Industrial Gas Turbine

Burke Aerospace

Burke Aerospace is proud to provide products and services to the world’s leading OEMs of heavy duty and aeroderivative gas turbines. Gas turbines find use in a multiple applications and environments including marine propulsion, transportation, oil and gas, renewable energy and industrial power generation. Burke Aerospace has a performance record of meeting and exceeding our customer’s quality and delivery requirements. Burke Aerospace is the supplier of choice for EDM and Milling.

Maintenance Repair & Overhaul

Burke Aerospace

Burke Aerospace has been an FAA certified Repair Station since 2010. Our highly talented Engineering & Operations team provides world-class turn-times to get your parts back in service when you need them.

People

Description

Burke Aerospace is a trusted partner for Turning of critical parts for the aerospace and industrial gas turbine industries. Burke Aerospace has turning capabilities up to 25’’ diameter components to support our strategic partners.

Share

Recent Chats

Share via email

Future: handle WhatsApp here

Future: handle LinkedIn here

Future: handle Twitter here

SUBMENU HERE

Share via Chat

Copy Link