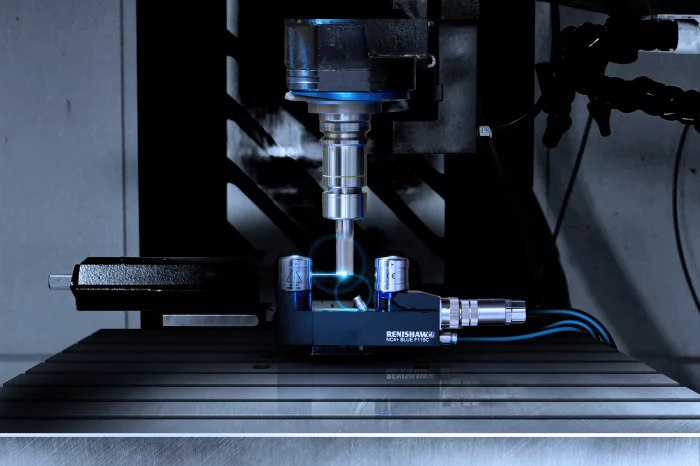

NC4+ Blue - Advanced laser tool setters for CNC machines

Our range of advanced laser tool setters for CNC machines provide high-precision, high-speed tool measurement and broken tool detection. Improve your process control with NC4 tool setters, suitable for all sizes and types of machine tools.

Description

More Products & Services

Products & Services

AGILITY® CMMs with 5-axis technology

Renishaw Sp. z o.o.

The AGILITY range of CMMs will help to increase the throughput and quality of your manufacturing with fully integrated dimensional measurement and surface roughness inspection. From the use of high-quality materials and components to the full optimisation of 5-axis measurement technology, AGILITY CMMs provide a high-speed, high-performance solution for the shop floor or metrology lab.

AGILITY CMMs bring together the pioneering technology and high-quality manufacturing that have gained Renishaw an unrivalled reputation for innovation in the most demanding industry sectors. The machines are designed to deliver all the advantages of the REVO multi-sensor 5-axis measurement system, including:

15% to 50% cycle time savings, compared to 3-axis measurement systems

Integrated dimensional inspection and surface roughness measurement

Infinite positioning for superior feature access

AGILITY S 5-axis multi-sensor CMMs for the shop floor:

Designed for shop floor environments

The S range of CMMs provides the ability to accurately measure parts in shop floor environments without temperature control. The rapid data capture speeds provided by 5-axis measurement reduce inspection cycle times, helping production departments keep pace with high volume manufacture. The systems work well in both stand-alone and fully automated production lines.

Rapid results at the point of manufacture

Results are captured at, or close to the point of manufacture, so production decisions can be made much faster. This replaces the traditional method of routing parts to centralised inspection facilities, reducing time and cost to the part and the risk associated with part handling.

Reducing operations

The multi-sensor capability of the system allows users to combine multiple checks in one automated part program. This gives production departments the ability to report on dimensional features and surface roughness callouts. AGILITY CMMs therefore minimise footprint and simplify measurement processes.

AGILITY L CMMs with 5-axis multi-sensor technology for laboratories:

Premium accuracy

The L range of CMMs delivers the performance needed by manufacturers operating in the top end of aerospace, automotive, consumer electronics and other precision engineering sectors. The most accurate machine has sub-micron accuracy, and even the largest L 163512 is specified at under 2 µm.

High throughput

The 5-axis functionality helps meet the throughput challenges of a machine operating in a controlled environment as an integral part of the manufacturing process. Fast inspection turnaround of development parts and production samples ensures verification is as efficient as possible.

Ultimate multi-sensor flexibility

Combining the infinite positioning of the REVO probe head with the most comprehensive range of sensors, AGILITY L machines are an ideal platform for developing new products and manufacturing processes. The surface finish probe will reach features previously inaccessible. The non-contact sensors will capture surface data without touching the part. The ultrasonic thickness probe simplifies inspection routines and often eliminates the need for part reorientation.

AGILITY CMMs bring together the pioneering technology and high-quality manufacturing that have gained Renishaw an unrivalled reputation for innovation in the most demanding industry sectors. The machines are designed to deliver all the advantages of the REVO multi-sensor 5-axis measurement system, including:

15% to 50% cycle time savings, compared to 3-axis measurement systems

Integrated dimensional inspection and surface roughness measurement

Infinite positioning for superior feature access

AGILITY S 5-axis multi-sensor CMMs for the shop floor:

Designed for shop floor environments

The S range of CMMs provides the ability to accurately measure parts in shop floor environments without temperature control. The rapid data capture speeds provided by 5-axis measurement reduce inspection cycle times, helping production departments keep pace with high volume manufacture. The systems work well in both stand-alone and fully automated production lines.

Rapid results at the point of manufacture

Results are captured at, or close to the point of manufacture, so production decisions can be made much faster. This replaces the traditional method of routing parts to centralised inspection facilities, reducing time and cost to the part and the risk associated with part handling.

Reducing operations

The multi-sensor capability of the system allows users to combine multiple checks in one automated part program. This gives production departments the ability to report on dimensional features and surface roughness callouts. AGILITY CMMs therefore minimise footprint and simplify measurement processes.

AGILITY L CMMs with 5-axis multi-sensor technology for laboratories:

Premium accuracy

The L range of CMMs delivers the performance needed by manufacturers operating in the top end of aerospace, automotive, consumer electronics and other precision engineering sectors. The most accurate machine has sub-micron accuracy, and even the largest L 163512 is specified at under 2 µm.

High throughput

The 5-axis functionality helps meet the throughput challenges of a machine operating in a controlled environment as an integral part of the manufacturing process. Fast inspection turnaround of development parts and production samples ensures verification is as efficient as possible.

Ultimate multi-sensor flexibility

Combining the infinite positioning of the REVO probe head with the most comprehensive range of sensors, AGILITY L machines are an ideal platform for developing new products and manufacturing processes. The surface finish probe will reach features previously inaccessible. The non-contact sensors will capture surface data without touching the part. The ultrasonic thickness probe simplifies inspection routines and often eliminates the need for part reorientation.

FORTiS™ - enclosed linear absolute encoder series

Renishaw Sp. z o.o.

An enclosed optical encoder houses the encoder's electronics and optics within a sealed unit that is attached to a readhead body. Both the sealed optical unit and the encoder's scale are further protected within a sealed enclosure. This design provides high resistance to the ingress of liquids and solid debris contaminants.

Customers can choose from two different extrusion profiles to suit their space requirements. The FORTiS-S™ linear encoder is the standard-sized encoder, available with measuring lengths from 140 mm to 4240 mm and is installed directly to a machined surface via flexure holes in the extrusion's body.

The FORTiS-N™ encoder, available with measuring lengths from 70 mm to 2040 mm, features a narrower cross-section extrusion and a more compact readhead to enable installations in confined spaces. This model can be mounted directly to a machined surface via two end cap mounting holes or a mounting spar for greater rigidity.

Renishaw FORTiS absolute encoder systems have CE approval and are manufactured in-house using strict quality-controlled processes that are certified to ISO 9001:2015 and backed by a global sales and support network.

Fortis series provide:

- Non-contact design – no mechanical wear and greater longevity

- Reduced hysteresis – smoother feedback and improved dynamic performance

- Breakthrough in readhead design – superior vibration resistance

- Uniquely sealed – greater resistance to contamination by fluids and solid debris

- Patented set-up LEDs – integral LED signal strength indicator for simple and quick installation and set-up

Customers can choose from two different extrusion profiles to suit their space requirements. The FORTiS-S™ linear encoder is the standard-sized encoder, available with measuring lengths from 140 mm to 4240 mm and is installed directly to a machined surface via flexure holes in the extrusion's body.

The FORTiS-N™ encoder, available with measuring lengths from 70 mm to 2040 mm, features a narrower cross-section extrusion and a more compact readhead to enable installations in confined spaces. This model can be mounted directly to a machined surface via two end cap mounting holes or a mounting spar for greater rigidity.

Renishaw FORTiS absolute encoder systems have CE approval and are manufactured in-house using strict quality-controlled processes that are certified to ISO 9001:2015 and backed by a global sales and support network.

Fortis series provide:

- Non-contact design – no mechanical wear and greater longevity

- Reduced hysteresis – smoother feedback and improved dynamic performance

- Breakthrough in readhead design – superior vibration resistance

- Uniquely sealed – greater resistance to contamination by fluids and solid debris

- Patented set-up LEDs – integral LED signal strength indicator for simple and quick installation and set-up

ASTRiA™ inductive rotary absolute encoders

Renishaw Sp. z o.o.

Fast, efficient, robust inductive encoder

The ASTRiA inductive rotary absolute encoder achieves an impressive total system accuracy of ±40 arc seconds and 23 bit resolution (for a Ø100 mm size), which is made possible by using a multi-track scale, robust mechanical design and advanced signal processing.

Other encoder features include:

- Built-in alignment flexures to ensure hassle-free installation. Whether for the initial setup or subsequent mounting operations, the ASTRiA encoder self-centres the rotor — significantly reducing installation time and effort.

- State-of-the-art electronics optimised for low current consumption. By minimising energy usage, customers benefit from reduced system running costs and an overall low cost of ownership.

- Carefully designed mechanical features on both the rotor and stator that enhance stability across a wide range of operating speeds and temperatures. Thermal expansion and high speeds do not compromise system operation.

- Standard RS485 serial communication, offering the BiSS® C (unidirectional) open serial interface. Baud rate of up to 10 MHz and request rates up to 32 kHz cater for even the most demanding customer applications.

The ASTRiA inductive rotary absolute encoder achieves an impressive total system accuracy of ±40 arc seconds and 23 bit resolution (for a Ø100 mm size), which is made possible by using a multi-track scale, robust mechanical design and advanced signal processing.

Other encoder features include:

- Built-in alignment flexures to ensure hassle-free installation. Whether for the initial setup or subsequent mounting operations, the ASTRiA encoder self-centres the rotor — significantly reducing installation time and effort.

- State-of-the-art electronics optimised for low current consumption. By minimising energy usage, customers benefit from reduced system running costs and an overall low cost of ownership.

- Carefully designed mechanical features on both the rotor and stator that enhance stability across a wide range of operating speeds and temperatures. Thermal expansion and high speeds do not compromise system operation.

- Standard RS485 serial communication, offering the BiSS® C (unidirectional) open serial interface. Baud rate of up to 10 MHz and request rates up to 32 kHz cater for even the most demanding customer applications.

Equator 300 - gauging systems for industrial manufacturing

Renishaw Sp. z o.o.

Shop floor gauging for industrial manufacturing

To control manufacturing processes on the shop floor, traditional gauges like callipers, go/no-go gauges or bore gauges have been used for decades. However, modern manufacturing requires high-speed operations, consistent measurement and adaptability to fast changing needs that gauges cannot deliver.

Equator gauging systems are high-speed gauges designed to provide speed, repeatability and ease of use for manual or automated applications in medium or high-volume manufacturing shop floors; which is why hundreds of manufacturers worldwide continue to replace their current gauging method with Equator systems.

Equator systems can be configured with hardware, software and accessory options to optimise manufacturing process and specific application, whether for manual or automated operations.

- Fast and efficient to keep up with production lines and reduce scrap

- Highly repeatable and accurate

- Thermally insensitive and designed for the shopfloor

- Versatile and reprogrammable

To control manufacturing processes on the shop floor, traditional gauges like callipers, go/no-go gauges or bore gauges have been used for decades. However, modern manufacturing requires high-speed operations, consistent measurement and adaptability to fast changing needs that gauges cannot deliver.

Equator gauging systems are high-speed gauges designed to provide speed, repeatability and ease of use for manual or automated applications in medium or high-volume manufacturing shop floors; which is why hundreds of manufacturers worldwide continue to replace their current gauging method with Equator systems.

Equator systems can be configured with hardware, software and accessory options to optimise manufacturing process and specific application, whether for manual or automated operations.

- Fast and efficient to keep up with production lines and reduce scrap

- Highly repeatable and accurate

- Thermally insensitive and designed for the shopfloor

- Versatile and reprogrammable

RESOLUTE™ optical absolute encoder series

Renishaw Sp. z o.o.

High-performance absolute position measurement

The RESOLUTE optical absolute encoder measures absolute position with fine resolutions down to 1 nm and high speeds up to 100 m/s. Advanced optics and innovative position determination algorithms deliver exceptional metrology performance. Low Sub-Divisional Error (SDE) and ultra-low noise (jitter) makes it suitable for demanding motion control challenges.

Application-specific variants include RESOLUTE Ultra-High Vacuum (UHV), RESOLUTE Extended Temperature Range (ETR) and RESOLUTE Functional Safety (FS).

Optional Advanced Diagnostic Tools and ADT View software acquire comprehensive real-time encoder data allowing optimisation and in-field fault finding.

The RESOLUTE optical absolute encoder measures absolute position with fine resolutions down to 1 nm and high speeds up to 100 m/s. Advanced optics and innovative position determination algorithms deliver exceptional metrology performance. Low Sub-Divisional Error (SDE) and ultra-low noise (jitter) makes it suitable for demanding motion control challenges.

Application-specific variants include RESOLUTE Ultra-High Vacuum (UHV), RESOLUTE Extended Temperature Range (ETR) and RESOLUTE Functional Safety (FS).

Optional Advanced Diagnostic Tools and ADT View software acquire comprehensive real-time encoder data allowing optimisation and in-field fault finding.

ATOM™ optical incremental encoder series

Renishaw Sp. z o.o.

Miniaturisation without compromise

The ATOM series is Renishaw's miniature non-contact optical incremental encoder system suitable for linear and rotary applications. Its innovative design combines miniaturisation with leading-edge signal stability, dirt immunity and reliability. This represents a significant advance in the performance and reliability of miniature encoders. ATOM is also the fastest encoder in its class, with maximum speeds up to 20 m/s.

ATOM systems are simple to install with integrated LED for signal integrity indication. They are compatible with Renishaw's ADTpro-100 diagnostic tool.

A range of high-speed interpolator interfaces is available including high-performance Ti, Ri and the compact PCB ACi interface, offering digital output with resolutions down to 1 nm.

The ATOM readhead is also available as a flexible printed circuit (FPC) variant which helps reduce overall package size, with a reduced Z-height.

The ATOM series is Renishaw's miniature non-contact optical incremental encoder system suitable for linear and rotary applications. Its innovative design combines miniaturisation with leading-edge signal stability, dirt immunity and reliability. This represents a significant advance in the performance and reliability of miniature encoders. ATOM is also the fastest encoder in its class, with maximum speeds up to 20 m/s.

ATOM systems are simple to install with integrated LED for signal integrity indication. They are compatible with Renishaw's ADTpro-100 diagnostic tool.

A range of high-speed interpolator interfaces is available including high-performance Ti, Ri and the compact PCB ACi interface, offering digital output with resolutions down to 1 nm.

The ATOM readhead is also available as a flexible printed circuit (FPC) variant which helps reduce overall package size, with a reduced Z-height.

REVO® - 5-axis measurement system

Renishaw Sp. z o.o.

Speed, accuracy, agility!

As a new installation or an accredited upgrade, the REVO 5-axis measurement system offers:

- Surface finish measurement and dimensional inspection.

- 15% to 50% cycle time savings.

- Maximised throughput, minimised capital investment.

The REVO system uses synchronised motion and 5-axis measurement technology to minimise the dynamic effects of CMM motion at ultra high measurement speeds.

High-speed measurement:

- Up to 500 mm/sec resulting in increased part throughput

- Data collection rates up to 4,000 points per second

- Infinite positioning and 5-axis motion reduces non-productive transitions between features

- Rapid calibration with all positions inferred means more time measuring

High system accuracy:

- 5-axis scanning minimises CMM motion and the associated dynamic errors

- Stylus wear minimised by extremely low scanning forces

- Infinite positioning and five-axis motion aid access to difficult features

- Tip-sensing further adds to the systems' accuracy and flexibility

Great flexibility

- Maximum reach up to 800 mm from centre of head rotation

- Multi-sensor probe and stylus changing capability

- Renishaw UCCserver software application (based on I++ DME command protocol) provides the interface for EVO-2 control

- The removable probe system, used in conjunction with a low cost changer, provides added system flexibility

As a new installation or an accredited upgrade, the REVO 5-axis measurement system offers:

- Surface finish measurement and dimensional inspection.

- 15% to 50% cycle time savings.

- Maximised throughput, minimised capital investment.

The REVO system uses synchronised motion and 5-axis measurement technology to minimise the dynamic effects of CMM motion at ultra high measurement speeds.

High-speed measurement:

- Up to 500 mm/sec resulting in increased part throughput

- Data collection rates up to 4,000 points per second

- Infinite positioning and 5-axis motion reduces non-productive transitions between features

- Rapid calibration with all positions inferred means more time measuring

High system accuracy:

- 5-axis scanning minimises CMM motion and the associated dynamic errors

- Stylus wear minimised by extremely low scanning forces

- Infinite positioning and five-axis motion aid access to difficult features

- Tip-sensing further adds to the systems' accuracy and flexibility

Great flexibility

- Maximum reach up to 800 mm from centre of head rotation

- Multi-sensor probe and stylus changing capability

- Renishaw UCCserver software application (based on I++ DME command protocol) provides the interface for EVO-2 control

- The removable probe system, used in conjunction with a low cost changer, provides added system flexibility

OSP60 scanning probe with SPRINT™ technology

Renishaw Sp. z o.o.

With unique 3D sensor technology, the OSP60 scanning probe with SPRINT technology provides the ultimate probing capability for users of CNC machine tools.

Incredibly responsive to surface variation and capable of detecting sub-micron movement at the probe stylus tip, our scanning probe captures 1,000 true 3D data points every second. Offering precision scanning and point measurement capability, it is the ideal solution for a diverse range of industrial applications.

Discover its unbeatable benefits:

- Rapid part measurement. Scanning provides incredible time savings with on-machine inspection and job set-up, increasing profitability and productive machining time.

- Determine feature form. Determine surface high-point / low-point or full feature form measurement.

- In-process control. Capture workpiece measurement results and keep on-machine processes under control, automatically. Output results for further analysis, or for quality assurance purposes.

Incredibly responsive to surface variation and capable of detecting sub-micron movement at the probe stylus tip, our scanning probe captures 1,000 true 3D data points every second. Offering precision scanning and point measurement capability, it is the ideal solution for a diverse range of industrial applications.

Discover its unbeatable benefits:

- Rapid part measurement. Scanning provides incredible time savings with on-machine inspection and job set-up, increasing profitability and productive machining time.

- Determine feature form. Determine surface high-point / low-point or full feature form measurement.

- In-process control. Capture workpiece measurement results and keep on-machine processes under control, automatically. Output results for further analysis, or for quality assurance purposes.

People

Description

Dimensional accuracy and part quality during the machining process can be affected by tool wear, run-out, and breakage. Renishaw's NC4 systems allow users to address these issues.

NC4 enables the measurement of a wide variety of tools at production feeds and speeds. This helps minimise the risk of machining poor parts due excessive tool wear or breakage.

As a premium laser tool setter for CNC machines, NC4 systems are a beneficial part of any manufacturer's in-process control procedures.

Featuring the industry-first blue laser technology and enhanced optics, NC4+ Blue systems enable high-precision, high-speed non-contact tool setting and tool breakage detection.

The NC4+ Blue measures and detects tools as small as 0.03 mm and to a repeatability of ±0.5 µm 2σ, ensuring the production of 'right first time' parts. The improved measurement performance associated with blue lasers minimises tool-to-tool measurement errors across a wide range of cutting tools, even micro tools.

NC4 enables the measurement of a wide variety of tools at production feeds and speeds. This helps minimise the risk of machining poor parts due excessive tool wear or breakage.

As a premium laser tool setter for CNC machines, NC4 systems are a beneficial part of any manufacturer's in-process control procedures.

Featuring the industry-first blue laser technology and enhanced optics, NC4+ Blue systems enable high-precision, high-speed non-contact tool setting and tool breakage detection.

The NC4+ Blue measures and detects tools as small as 0.03 mm and to a repeatability of ±0.5 µm 2σ, ensuring the production of 'right first time' parts. The improved measurement performance associated with blue lasers minimises tool-to-tool measurement errors across a wide range of cutting tools, even micro tools.

Share

Recent Chats

Share via email

Future: handle WhatsApp here

Future: handle LinkedIn here

Future: handle Twitter here

SUBMENU HERE

Share via Chat

Copy Link