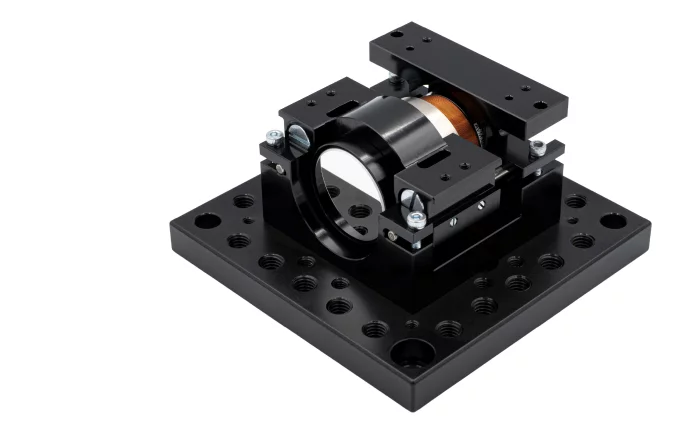

High-Dynamics Voice-Coil Nano-Positioner

Closed-loop feedback resolves 40 nm increments

360 µm move settles to ±1 µm within 10 ms

Full 2.88 mm return only requires 20 ms

High-Dynamics Voice-Coil Nano-Positioner

The motor supplies 24.9 N peak and 5.62 N continuous force, driving the stage to 150 mm/s and up to 9 g.

Z stroke :

2880 μm (extensible to 7000 μm)

Z position accuracy :

360μm in 10ms: ±1μm / 360μm in 6ms: ±2.5μm

Z minimal incremental motion :

40 nm

Z max speed :

150mm/s

Z peak force :

24.9 N

Z continuous force :

5.62 N

Description

More Products & Services

Products & Services

High-speed coaxial lens actuator

MPS bearings Co., Ltd.

Designed on MPS Microsystems’ modular optomechanics platform, the High-Speed Coaxial Lens Actuator delivers custom-engineered, micron-level alignment in a footprint of just 170 × 87 × 45 mm. Two brushless motors drive lens holders (Ø 12.7 mm) that move in the same precision-machined bore, guaranteeing perfect coaxiality throughout the 3.75 mm stroke and no shimming or iterative alignment required.

The closed-loop cam mechanism runs friction-free, ensuring a maintenance-free stage that can be used in laser machining heads, spectrometers or 3-D scanners and keeps working for millions of cycles. Most importantly, stroke, motor, encoder and mounting interfaces of this high-speed coaxial lens actuator can all be customized to fit your needs with regards to optical and space constraints.

The closed-loop cam mechanism runs friction-free, ensuring a maintenance-free stage that can be used in laser machining heads, spectrometers or 3-D scanners and keeps working for millions of cycles. Most importantly, stroke, motor, encoder and mounting interfaces of this high-speed coaxial lens actuator can all be customized to fit your needs with regards to optical and space constraints.

Multiaxis micropositioning stage

MPS bearings Co., Ltd.

Driven by two micro motors strategically positioned at the edges of the assembly, the design remains ultra-thin, making it ideal for through-hole configurations in optical applications requiring precise transmission.

The innovative symmetry of the flexure plates allows for a range of mechanical displacements, enabling unique combinations that can be tailored to your needs. Whether you require extended strokes, precise X-Y stage movement, an additional Z dimension for an X-Y-Z system, or independent lateral displacements of two objects, our multiaxis micropositioning stage is designed to adapt.

Scalability is at the heart of this design. By adjusting a few key dimensions, the multiaxis micropositioning plate can be customized to meet the specific requirements of applications that demand smooth motion, long-lasting durability, and maintenance-free, repeatable positioning.

The innovative symmetry of the flexure plates allows for a range of mechanical displacements, enabling unique combinations that can be tailored to your needs. Whether you require extended strokes, precise X-Y stage movement, an additional Z dimension for an X-Y-Z system, or independent lateral displacements of two objects, our multiaxis micropositioning stage is designed to adapt.

Scalability is at the heart of this design. By adjusting a few key dimensions, the multiaxis micropositioning plate can be customized to meet the specific requirements of applications that demand smooth motion, long-lasting durability, and maintenance-free, repeatable positioning.

Fin actuator

MPS bearings Co., Ltd.

This miniature fin actuator manufactured by MPS Microsystems was designed based on customer specifications. Designed to guide a very small object and disposing of an extremely limited space, it meets strict requirements in terms of performance, weight - less than 100 g - and dimensions. To reduce the length of this actuator, MPS Microsystems used part of the screw length as the motor axis. This screw is equipped with a very compact 4-point contact bearing that simultaneously absorbs axial and radial loads. The angular play on the aileron axis is less than 0.1° rms.

This actuator meets the storage and vibration requirements of military equipment.

This actuator meets the storage and vibration requirements of military equipment.

Coaxial lens actuator

MPS bearings Co., Ltd.

This very compact optical system with an original design allows two groups of lenses to be moved in perfect coaxiality (+/- 1µm) over several millimeters. It is particularly recommended for applications requiring a constant alignment precision when moving the lenses. The perfect coaxiality of the lens holders is guaranteed by a common bore machined in a single operation. Numerous dimensional modifications allow a perfect adaptation to the optical design related to its application. Due to the use of perfectly adjusted ball cages, its low-friction translation mechanism is best suited for intense use and offers an unequalled lifetime without any particular maintenance.

Linear actuators

MPS bearings Co., Ltd.

MPS linear actuators are very compact, offer outstanding precision and can be adapted to the most demanding environments. The ball screws that make up these actuators give them a smooth, stick-slip-free linear motion. The diameter, motor, screw type and other elements of the linear actuator can be configured to your requirements.

Zoom mechanism

MPS bearings Co., Ltd.

This miniaturized system allows, depending on the desired configuration, to move very precisely between 1 and 3 sets of lenses over a stroke of several centimeters. The design has been optimized to ensure perfect alignment of the lenses and to minimize their tilt throughout the movement. This optomechanical system mainly consists of high-precision standard MPS and FAULHABER modules, such as brushless or stepper motors, ground ball screws with double nuts and linear ball bearings. It is particularly recommended for focusing a laser over a long distance, for example for the guidance of unmanned flying objects or for communication between flying objects. The number of lens sets, lens size and stroke can be configured at will.

Laser guidance system

MPS bearings Co., Ltd.

Developed and manufactured by MPS Microsystems based on customer specifications, this lens actuator forms an essential component of a laser guidance system for unmanned flying objects. It enables 2 lens groups to be displaced individually over a total range of 48 mm and makes it possible to focus a laser over a distance of several kilometres.

The main technical difficulty inherent to this actuator lies in meeting very stringent requirements for alignment between the two lens groups (< 10 µm) and in maintaining a very small tilt of the lenses over their entire stroke (lateral deviation < 2 µm).

The key part making it possible to ensure such specifications is a frame machined by milling from an aluminium block, into which the 2 drive systems are fastened. These systems each consist of a Ø16 mm brushless motor and a Ø4 mm ball screw with an axial play of less than 5 µm. Backlash-free and frictionless sliding of the lens holders is ensured by standard L306 linear ball bearings manufactured by MPS Microsystems.

The main technical difficulty inherent to this actuator lies in meeting very stringent requirements for alignment between the two lens groups (< 10 µm) and in maintaining a very small tilt of the lenses over their entire stroke (lateral deviation < 2 µm).

The key part making it possible to ensure such specifications is a frame machined by milling from an aluminium block, into which the 2 drive systems are fastened. These systems each consist of a Ø16 mm brushless motor and a Ø4 mm ball screw with an axial play of less than 5 µm. Backlash-free and frictionless sliding of the lens holders is ensured by standard L306 linear ball bearings manufactured by MPS Microsystems.

Ball screws

MPS bearings Co., Ltd.

MPS Microsystems offers a complete range of high precision ball screws for positioning less than 5 µm. Mostly custom-made, these screws ensure smooth and uniform movement resulting from the high precision of their thread, achieved by grinding.

Our ball screws are made exclusively of stainless steel and are fitted with double nuts to allow fine adjustment of the axial play. Moreover, an optional ogival thread can provide a higher static and dynamic load capacity.

Thanks to a large number of options, we can ensure that the ball screw meets your technical and quality needs. The following parameters can be personalized: lubricant (grease, oil, dry lubrication, no lubrication), customized screw ends, shape and external dimensions of the nut and screw, multiple nuts on the same screw, left-hand thread, thread length, specific axial play, special surface treatment, and more.

Our ball screws are made exclusively of stainless steel and are fitted with double nuts to allow fine adjustment of the axial play. Moreover, an optional ogival thread can provide a higher static and dynamic load capacity.

Thanks to a large number of options, we can ensure that the ball screw meets your technical and quality needs. The following parameters can be personalized: lubricant (grease, oil, dry lubrication, no lubrication), customized screw ends, shape and external dimensions of the nut and screw, multiple nuts on the same screw, left-hand thread, thread length, specific axial play, special surface treatment, and more.

Control Actuation System (CAS)

MPS bearings Co., Ltd.

This Control Actuation System (CAS) is a guidance system for unmanned flying objects. It consists of three MPS fin actuators that each independently position an aerodynamic fin. The maximum angle of incidence is ±8°, which allows the device to carry out highly precise dynamic manoeuvres.

The miniature fin actuators that make up this Control Actuation System are manufactured by MPS Microsystems and were designed based on customer specifications. Designed to guide a very small object and disposing of an extremely limited space, these fin actuators meet strict requirements in terms of performance, weight - less than 100 g - and dimensions. To reduce the length of this actuator, MPS Microsystems used part of the screw length as the motor axis. This screw is equipped with a very compact 4-point contact bearing that simultaneously absorbs axial and radial loads. The angular play on the aileron axis is less than 0.1° rms. This actuator meets the storage and vibration requirements of military equipment.

The miniature fin actuators that make up this Control Actuation System are manufactured by MPS Microsystems and were designed based on customer specifications. Designed to guide a very small object and disposing of an extremely limited space, these fin actuators meet strict requirements in terms of performance, weight - less than 100 g - and dimensions. To reduce the length of this actuator, MPS Microsystems used part of the screw length as the motor axis. This screw is equipped with a very compact 4-point contact bearing that simultaneously absorbs axial and radial loads. The angular play on the aileron axis is less than 0.1° rms. This actuator meets the storage and vibration requirements of military equipment.

Linear bearings - L series

MPS bearings Co., Ltd.

MPS Microsystems is specialized in manufacturing high-precision, miniature linear bearings. We offer a comprehensive range of exceptionally smooth bearings with bore diameters from Ø 2 mm to Ø 6 mm.

The balls of these precision bearings meet ‘Grade 3’, the highest quality defined by the ISO 3290/DIN 5401 standard. Combined with a cage and a high precision casing, they allow rapid positioning while reducing friction and eliminating the stick-slip effect.

The standard version of MPS Microsystems linear bearings consists of a stainless steel bushing and balls, and a brass cage. An all-stainless steel version or one with ceramic balls can be made on request.

The balls of these precision bearings meet ‘Grade 3’, the highest quality defined by the ISO 3290/DIN 5401 standard. Combined with a cage and a high precision casing, they allow rapid positioning while reducing friction and eliminating the stick-slip effect.

The standard version of MPS Microsystems linear bearings consists of a stainless steel bushing and balls, and a brass cage. An all-stainless steel version or one with ceramic balls can be made on request.

Description

Developed by MPS Microsystems, the voice-coil nano-positioner unites a Lorentz-force motor, flexure guidance and on-board electronics inside a 65 × 60 × 38 mm envelope. Standard travel is 2.88 mm, extendable to 7 mm with the same coil, suiting microscope objectives, small mirrors and sensors that demand friction-free motion.

Bidirectional repeatability stays within ±1 µm over a 360 µm stroke and ±2.5 µm across the full stroke. We can tailor mounting plates, objective clamps and cable exits to suit your specific requirements, ensuring that this voice-voil actuator can be integrated seamlessly into your system.

Bidirectional repeatability stays within ±1 µm over a 360 µm stroke and ±2.5 µm across the full stroke. We can tailor mounting plates, objective clamps and cable exits to suit your specific requirements, ensuring that this voice-voil actuator can be integrated seamlessly into your system.

Share

Recent Chats

Share via email

Future: handle WhatsApp here

Future: handle LinkedIn here

Future: handle Twitter here

SUBMENU HERE

Share via Chat

Copy Link