OmniDockTM

Improve Operational Readiness

Move from island to island, shipyard to shipyard, or port to port with the aid of tugboats.

No Ballasting Required

No risk of introducing potentially harmful invasive species.

Service Multiple Vessels at a Time

The OmniDock™ can move as many vessels onto land as the yard has space for.

Tide-Independent

Elevate the platform to match the quayside.

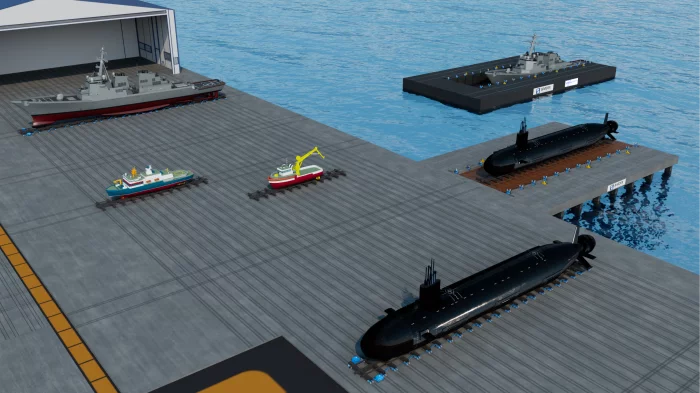

OmniDockTM

Floating Drydocks, Reimagined.

Can’t decide between an OmniLift®, wire rope shiplift, or floating drydock? Skip the trade-offs and get the best of each with the world’s only OmniDock™

Description

More Products & Services

Products & Services

Dry Dock Conversion

Bardex Corporation

The OmniLift name is derived from the Latin word for “all,” and we take its moniker seriously. Experience one seamless solution designed to meet every docking need, every time.

OmniLift® Shiplift

Bardex Corporation

Our chain jack shiplift technology is the gold standard in accuracy, reliability, and sustained value over the 40+ year service life you can expect from your investment. Why?

Fewer Moving Parts → Less Maintenance → Less Downtime → More Revenue & Less Hassle. Win-Win.

Maintenance-prone items, such as variable frequency drives (VFDs) susceptible to overheating, gearboxes, brakes, bearings, sheaves, and wire ropes, are nowhere to be found in our shiplift designs. Neither is environmental pollution caused by submerging greased wire ropes and sheaves. And our chain based system will never experience a failure resulting from a rope skipping a sheave, snagging, and breaking due to debris lodged in the submerged lower sheaves. This risk is unique to operating a wire rope shiplift block underwater that does not normally occur with other similar types of marine or land based wire rope lifting equipment. Modern-day genius at its simple best.

Fewer Moving Parts → Less Maintenance → Less Downtime → More Revenue & Less Hassle. Win-Win.

Maintenance-prone items, such as variable frequency drives (VFDs) susceptible to overheating, gearboxes, brakes, bearings, sheaves, and wire ropes, are nowhere to be found in our shiplift designs. Neither is environmental pollution caused by submerging greased wire ropes and sheaves. And our chain based system will never experience a failure resulting from a rope skipping a sheave, snagging, and breaking due to debris lodged in the submerged lower sheaves. This risk is unique to operating a wire rope shiplift block underwater that does not normally occur with other similar types of marine or land based wire rope lifting equipment. Modern-day genius at its simple best.

Wire Rope Shiplift Conversion

Bardex Corporation

Retrofit without compromise. OmniLift integrates into existing infrastructure, avoiding the cost, downtime, and disruption of full replacement.

Engineered for durability. With solid-link chain and guided motion, OmniLift eliminates the hidden wear and unpredictable failure modes of wire rope.

Built-in redundancy. Fail-safe by design, OmniLift™ offers multiple load paths to keep your operations running—even when the unexpected happens.

Engineered for durability. With solid-link chain and guided motion, OmniLift eliminates the hidden wear and unpredictable failure modes of wire rope.

Built-in redundancy. Fail-safe by design, OmniLift™ offers multiple load paths to keep your operations running—even when the unexpected happens.

People

Description

Bardex’s Floating OmniDock™ revolutionizes ocean launching and recovery capabilities. From traditional commercial and military vessels to offshore wind turbines to the uncrewed vessels of the future, the Floating OmniDock™ is infrastructure on the move. Choose from concrete, steel, or a hybrid approach depending on your operational goals and available resources.

Concrete

Supported by the Safier Ingenierie sas ALFOWT modular floating hub and C2C construction method, choosing a single-material concrete OmniDock offers a turn-key solution while avoiding the shipping costs associated with large steel structures.

Steel

Do you have steel fabrication resources available on-site? This build-to-print option for the supporting structure of the OmniDock can greatly reduce your CAPEX.

Hybrid Concrete-Steel

Each project has different resources available and different challenges to address. Choosing a steel topped, concrete base structure for the OmniDock can offer a longer design life with less maintenance cost compared to a pure steel design while still offering the benefits of building, launching and connecting modular concrete caissons found in a uniform concrete design.

Concrete

Supported by the Safier Ingenierie sas ALFOWT modular floating hub and C2C construction method, choosing a single-material concrete OmniDock offers a turn-key solution while avoiding the shipping costs associated with large steel structures.

Steel

Do you have steel fabrication resources available on-site? This build-to-print option for the supporting structure of the OmniDock can greatly reduce your CAPEX.

Hybrid Concrete-Steel

Each project has different resources available and different challenges to address. Choosing a steel topped, concrete base structure for the OmniDock can offer a longer design life with less maintenance cost compared to a pure steel design while still offering the benefits of building, launching and connecting modular concrete caissons found in a uniform concrete design.

Share

Recent Chats

Share via email

Future: handle WhatsApp here

Future: handle LinkedIn here

Future: handle Twitter here

SUBMENU HERE

Share via Chat

Copy Link