See us at Farnborough International Airshow 2026 : 2525

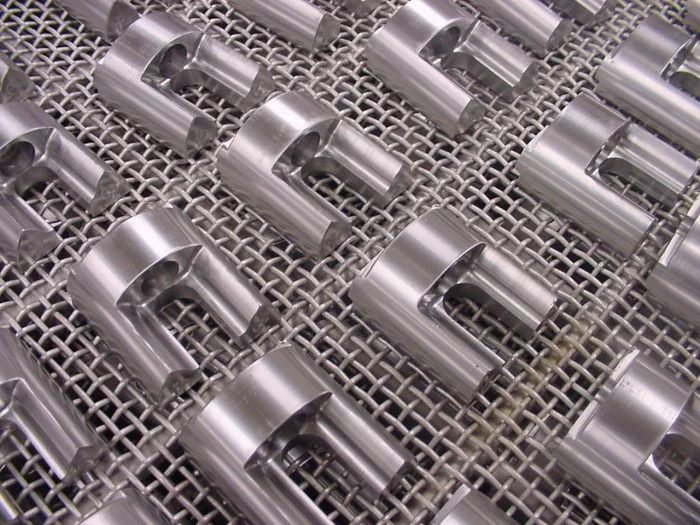

Vacuum Hardening & Tempering

Vacuum hardening prevents high temperature oxidation and decarburization, while gas quenching from vacuum minimizes distortion over traditional oil quenching.

Description

More Products & Services

Products & Services

Vacuum Annealing

Solar Atmospheres

Solar Atmospheres provides vacuum annealing services to millions of pounds of materials every year. The primary reason most customers desire an anneal heat treatment is to reduce hardness and increase ductility making the metal more workable for subsequent downstream operations.

Vacuum Degassing Services

Solar Atmospheres

Vacuum degassing services remove detrimental elements such as hydrogen, nitrogen and oxygen, which may be harmful to the integrity of the metal. Hydrogen is one of the more common interstitial impurities which requires degassing. Vacuum degassing can be used for very small impurity levels (<100 ppm) to very high hydrogen levels.

Vacuum Stress Relieving

Solar Atmospheres

Welding, machining, milling, and cold working all induce stresses within materials. These stresses will cause unstable dimensional control downstream if not relieved thermally. Vacuum metal stress relieving is normally performed after rough machining, prior to final machining. Solar's vacuum metal stress relieving produces bright, clean surface finishes, therefore often the part is stress relieved in a near net shape.

Solar Expedition: Heat Treatment of Titanium

Solar Atmospheres

Vacuum heat treating titanium without surface contamination. For more information on the heat treatment of titanium, visit: https://solaratm.com

Vacuum Brazing

Solar Atmospheres

Fluxless vacuum brazing services from Solar Atmospheres allows you to join metals while keeping the assembly bright and clean. Unlike soldering or welding, even complex shapes can be brazed with little distortion.

Solar Expedition - Stress Relieving

Solar Atmospheres

Metal stress relieving by utilizing vacuum thermal processing.

Carburizing

Solar Atmospheres

Vacuum Age Hardening

Solar Atmospheres

Certain metal alloys may be strengthened by a relatively low temperature process called precipitation age hardening. As in annealing, brazing, and stress relieving, vacuum age hardening may assure the parts remain bright at the outset. Precise temperature control is paramount in vacuum age hardening and many times Nadcap accreditation and ITAR registration are requirements.

People

Marketing

Solar Atmospheres

Bob Hill

Solar Atmospheres

President, Western PA and Michigan

Derek Dennis

Solar Atmospheres

President, California

Frank Trujillo

Solar Atmospheres

Vice President of Sales, California

Keith Reim

Solar Atmospheres

Corporate Marketing Director

Farnborough International Airshow 2026

Mike Johnson

Solar Atmospheres

Sales Director, Western PA

Mike Johnson

Solar Atmospheres

Description

As in annealing, brazing, and stress relieving, vacuum metal processing of tooling and high strength steel can give you an advantage over conventional hardening and tempering. Vacuum hardening prevents high temperature oxidation and decarburization, while gas quenching from vacuum minimizes distortion over traditional oil quenching. Vacuum tempering keeps parts bright and clean with no temper scale.

Share

Recent Chats

Share via email

Future: handle WhatsApp here

Future: handle LinkedIn here

Future: handle Twitter here

SUBMENU HERE

Share via Chat

Copy Link