US ALUMINUM CASTINGS

US Aluminum Castings’ Core Focus is to manufacture Quality Aluminum Castings in an AS9100D Aerospace Certified Foundry using Green Sand, Dry Sand, & Permanent Mold Processes with in-house machining, powder coating, some sub-assemblies, and Nadcap accredited heat treat and NDT.

Entiat, Washington (WA), United States

Aerospace

Products & Services

People

About

Products & Services

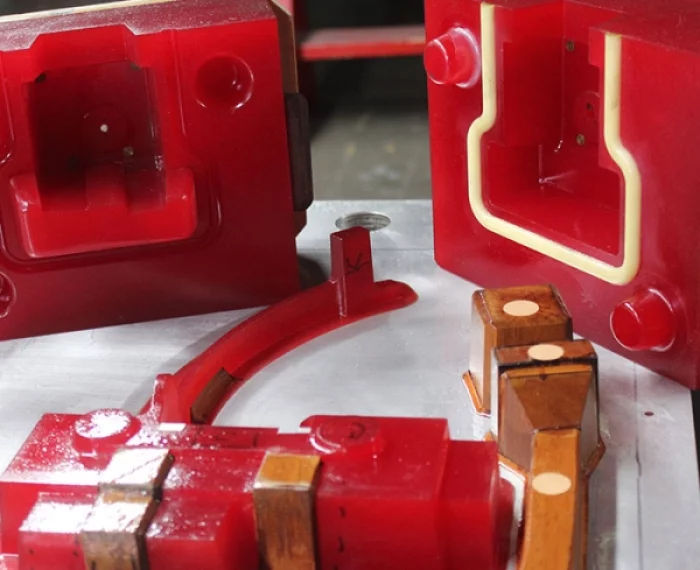

ENGINEERING DESIGN

US Aluminum Castings

US Aluminum Castings has an engineering department with over 60+ years of combined tooling design experience. By pairing highly experienced foundry designers with recent graduate level engineers, our design team is able to provide tried and true design methodology backed by cutting edge solidification modeling, CAD analysis, and an A9100D certified tooling design and development process.

We work hard to develop high quality, cost efficient casting tooling and machining fixtures consistent with the needs of our customers.

We work hard to develop high quality, cost efficient casting tooling and machining fixtures consistent with the needs of our customers.

HEAT TREAT

US Aluminum Castings

When initially poured, aluminum castings do not have their full potential material strength. In order to drastically improve the material performance of cast aluminum, each casting must undergo a heat treat process. This process involves first homogenizing the molecular structure of the metal through a gradual heating cycle and then quickly quenching the material in a water bath. This process, in combination with artificial aging, ensures that each casting has uniform material properties that are reliable to the specific alloy/material performance requirements of our customers.

In order to ensure that we are able to continually provide our customers with quality castings, our heat treat department has been certified to Nadcap AS7102, and we have recently made a large capitol investment in new, state of the art, automated heat treat equipment.

In order to ensure that we are able to continually provide our customers with quality castings, our heat treat department has been certified to Nadcap AS7102, and we have recently made a large capitol investment in new, state of the art, automated heat treat equipment.

People

About

US Aluminum Castings was founded in Seattle, Washington in 1909 as part of the Morel Foundry family. For the next 8 decades, USAC supplied quality castings to the growing US commercial, aerospace and industrial sectors. While growing in capabilities and product demand, the need for additional manufacturing space became increasingly apparent. In 1994, 85 years after opening its doors, US Aluminum Castings relocated to Entiat, Washington, along the banks of the Columbia River. This new location expanded our foundry to 100,000 sq ft and allows USAC to offer its customers a myriad of casting processes, accredited value-added services, and the use of environmentally friendly, renewable hydroelectric power.

Add Attachment

Share

Recent Chats

Share via email

Future: handle WhatsApp here

Future: handle LinkedIn here

Future: handle Twitter here

SUBMENU HERE

Share via Chat

Copy Link