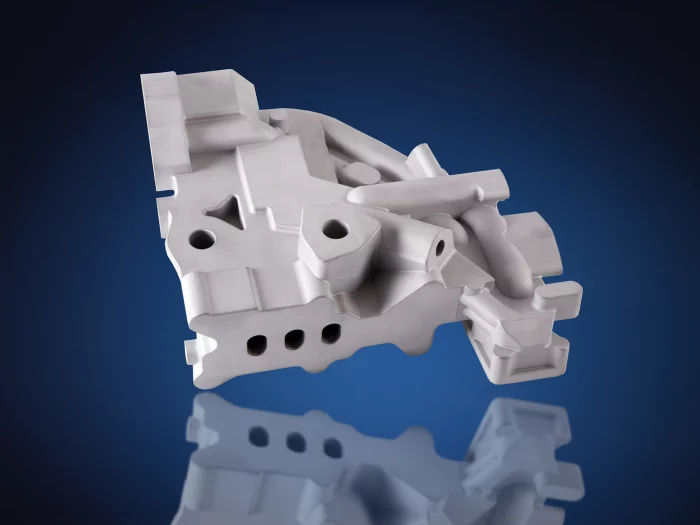

Aluminum Investment Castings

The casting of Aluminum Alloys comprises the largest part of O’Fallon Casting’s business. Most common are aluminum-silicon alloys 356 / A356 / C355 / A357 / F357. Our Aluminum Castings are used extensively in the Aerospace, Defense and Medical industries

Description

More Products & Services

Products & Services

Al / SiC Metal Matrix Composite (MMC)

O'Fallon Casting

O’Fallon Casting is the preeminent manufacturer of Investment Cast Al/SiC Metal Matrix Composite (MMC) castings in the world today. Its family of cast MMC’s contains particles of Silicon Carbide, ranging in size of 9 to 38 microns, homogeneously suspended in an aluminum matrix. The particle density can be varied, from 20%-40% Silicon Carbide by volume to create different properties of MMC.

Although MMC’s are difficult to machine, Investment Casting produces them in Near Net Shapes that helps to minimize the machining content.

Al/SiC MMC’s have Coefficients of Thermal Expansion and Specific Stiffness similar to cast Beryllium Aluminum but without the potential health hazard.

Although MMC’s are difficult to machine, Investment Casting produces them in Near Net Shapes that helps to minimize the machining content.

Al/SiC MMC’s have Coefficients of Thermal Expansion and Specific Stiffness similar to cast Beryllium Aluminum but without the potential health hazard.

Complete to Print

O'Fallon Casting

Do you need something more than just a raw casting? O’Fallon Casting offers a wide range of post cast services, allowing our customers to bypass the supply chain and buy a completed product!

As part of its Complete to Print Service, O’Fallon Casting will engage and administrate sub-tier purchase orders with qualified subcontractors to perform any necessary secondary operations including:

Machining

EDM

Coatings

Assembly

Product Testing

O’Fallon Casting assures that the quality and delivery of its Turnkey products are compliant to the requirements of its customer contract.

As part of its Complete to Print Service, O’Fallon Casting will engage and administrate sub-tier purchase orders with qualified subcontractors to perform any necessary secondary operations including:

Machining

EDM

Coatings

Assembly

Product Testing

O’Fallon Casting assures that the quality and delivery of its Turnkey products are compliant to the requirements of its customer contract.

Rapid Prototype Castings

O'Fallon Casting

Small quantities of prototype castings can be quickly manufactured by O’Fallon Casting, directly from a Customer supplied CAD file. Rapid Prototype Castings may fit a customer needs for:

Reduced Time-to-Market

Design Mock-up and Error proofing

Qualification

Low Rate Manufacturing

O’Fallon Casting Rapid Prototypes exhibit the superior attributes of fine surface finish and dimensional precision as a part produced by hard tooling. Should you have an urgent requirement for small quantities of metal parts, contact O’Fallon Casting to learn more of how Rapid Prototype castings can best fill that need.

Reduced Time-to-Market

Design Mock-up and Error proofing

Qualification

Low Rate Manufacturing

O’Fallon Casting Rapid Prototypes exhibit the superior attributes of fine surface finish and dimensional precision as a part produced by hard tooling. Should you have an urgent requirement for small quantities of metal parts, contact O’Fallon Casting to learn more of how Rapid Prototype castings can best fill that need.

People

Description

The casting of Aluminum Alloys comprises the largest part of O’Fallon Casting’s business. Most common are aluminum-silicon alloys 356 / A356 / 354 / C355 / A357 / F357. These alloys have excellent castability, weldability, pressure tightness and corrosion resistance. They are heat treatable and can be provided in various combinations of physical properties

The most frequently cast aluminum alloys are 356 and its higher purity version, A356. These are good general purpose alloys and because they are in wide use are advantageous in terms of cost and delivery.

The most frequently cast aluminum alloys are 356 and its higher purity version, A356. These are good general purpose alloys and because they are in wide use are advantageous in terms of cost and delivery.

Share

Recent Chats

Share via email

Future: handle WhatsApp here

Future: handle LinkedIn here

Future: handle Twitter here

SUBMENU HERE

Share via Chat

Copy Link