Additive Manufacturing

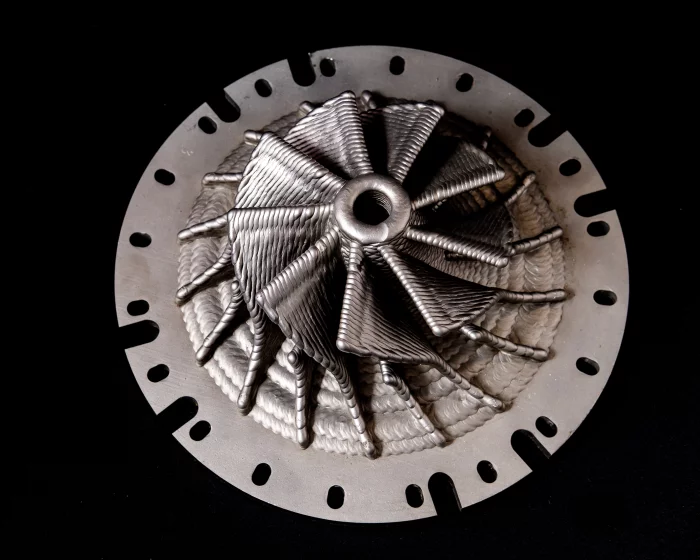

Manufacture of large-scale with high complexity parts using WAAM and Laser Wire DED

Description

More Products & Services

Products & Services

Reverse Engineering

Fastech LLC

Handheld 3D scanners for fast, accurate 3D models & reverse engineering

FasTech is the US agent for the Scantech range of portable 3D scanners. These state-of-the-art scanners are ideal for rapidly creating exact 3D models for product development, reverse engineering, first article inspection (FAI), quality control and repair and maintenance. The handheld scanners, which can measure and scan large or awkward shapes, automatically transform the 3D scan data into accurate 3D models with part measurement accuracy within as little as less than a 10th Thou (0.0008”) or 20 microns.

Not only are these 3D scanners ideal for our work at FasTech, helping us reverse model complex parts with curved surfaces, ribs or cavities – they also have numerous applications across a broad range of industries including aerospace, automotive, transport, energy and defense.

FasTech is the US agent for the Scantech range of portable 3D scanners. These state-of-the-art scanners are ideal for rapidly creating exact 3D models for product development, reverse engineering, first article inspection (FAI), quality control and repair and maintenance. The handheld scanners, which can measure and scan large or awkward shapes, automatically transform the 3D scan data into accurate 3D models with part measurement accuracy within as little as less than a 10th Thou (0.0008”) or 20 microns.

Not only are these 3D scanners ideal for our work at FasTech, helping us reverse model complex parts with curved surfaces, ribs or cavities – they also have numerous applications across a broad range of industries including aerospace, automotive, transport, energy and defense.

Milling

Fastech LLC

By integrating computer numerically controlled (CNC) systems, computer-aided manufacturing (CAM), and industry-leading software with our extensive machining expertise, we deliver flawless products based on customer CAD designs. Our CNC machining specialists expertly program and manage the production of highly intricate precision parts, ensuring the highest standards of quality, reproducibility, and safety.

We take pride in having the most skilled CNC engineers in Southern Virginia and utilizing the best tooling and equipment available. Our team comprises top engineers handpicked from well-known companies to uphold our commitment to quality and performance.

Check our full milling capacity on the link below:

https://fastech-engineering.com/about/capabilities

We take pride in having the most skilled CNC engineers in Southern Virginia and utilizing the best tooling and equipment available. Our team comprises top engineers handpicked from well-known companies to uphold our commitment to quality and performance.

Check our full milling capacity on the link below:

https://fastech-engineering.com/about/capabilities

Turning

Fastech LLC

CNC Turning is an expanding department within Fastech, using the latest machinery and software with the most up to date tooling and techniques from the leading tooling suppliers.

With a capacity to turn up to 400mm in diameter and 600mm in length and with offline programming using Autodesk Powermill software, we can produce a wide range of parts from a wide range of sectors whilst making the CNC Turning department flexible and cost-efficient.

We provide unprecedented consistency and repeatability providing excellent quality and accuracy throughout an entire batch of components and have the experience and ability to machine intricate components out of the most demanding materials.

We are flexible with different types of components and machining methods including using bespoke tooling, chucks, fixtures, forgings or castings. Materials machined include: Inconels, Super Duplex, Titanium, 316, 17/4, 440, 4140, 3130, Aluminum.

Each machine is running for 120hrs between Mon – Fri with additional hours available at the weekend as required depending on customer needs. We pride ourselves on customer success in order to help our customer’s with emergency cover for those special rush jobs or part modifications.

With a capacity to turn up to 400mm in diameter and 600mm in length and with offline programming using Autodesk Powermill software, we can produce a wide range of parts from a wide range of sectors whilst making the CNC Turning department flexible and cost-efficient.

We provide unprecedented consistency and repeatability providing excellent quality and accuracy throughout an entire batch of components and have the experience and ability to machine intricate components out of the most demanding materials.

We are flexible with different types of components and machining methods including using bespoke tooling, chucks, fixtures, forgings or castings. Materials machined include: Inconels, Super Duplex, Titanium, 316, 17/4, 440, 4140, 3130, Aluminum.

Each machine is running for 120hrs between Mon – Fri with additional hours available at the weekend as required depending on customer needs. We pride ourselves on customer success in order to help our customer’s with emergency cover for those special rush jobs or part modifications.

People

Description

With our GEFERTEC Machines (WAAM Technology) we offer efficient fabrication of large metal components with reduced waste, faster production times, and cost advantages.

- High Material Utilization: WAAM achieves nearly 100% material utilization, significantly reducing waste and cost.

- Large Part Production: It excels in producing large-scale components, making it ideal for industries like aerospace and heavy machinery.

- Five-Axis Deposition: Parts can be created without the need for additional support structures, thanks to five-axis weld deposition capabilities.

- Rapid Prototyping and Production: WAAM’s efficiency allows for faster lead times compared to traditional manufacturing methods.

But also, our LW-DED Process Powered by Meltio allows us to offer unparalleled precision for printing intricate designs and repairing high-value components with minimal heat input and distortion.

- Precision and Flexibility: The laser provides exceptional precision, allowing for the creation of highly detailed and complex parts.

- Material Versatility: LW-DED can work with a wide range of metals, making it suitable for diverse applications across multiple industries.

- Superior Quality: The controlled environment ensures high-quality outputs with excellent mechanical properties.

- On-Demand Production: Ideal for both new part manufacturing and the repair of existing components, reducing downtime and extending the life of critical parts.

- High Material Utilization: WAAM achieves nearly 100% material utilization, significantly reducing waste and cost.

- Large Part Production: It excels in producing large-scale components, making it ideal for industries like aerospace and heavy machinery.

- Five-Axis Deposition: Parts can be created without the need for additional support structures, thanks to five-axis weld deposition capabilities.

- Rapid Prototyping and Production: WAAM’s efficiency allows for faster lead times compared to traditional manufacturing methods.

But also, our LW-DED Process Powered by Meltio allows us to offer unparalleled precision for printing intricate designs and repairing high-value components with minimal heat input and distortion.

- Precision and Flexibility: The laser provides exceptional precision, allowing for the creation of highly detailed and complex parts.

- Material Versatility: LW-DED can work with a wide range of metals, making it suitable for diverse applications across multiple industries.

- Superior Quality: The controlled environment ensures high-quality outputs with excellent mechanical properties.

- On-Demand Production: Ideal for both new part manufacturing and the repair of existing components, reducing downtime and extending the life of critical parts.

Share

Recent Chats

Share via email

Future: handle WhatsApp here

Future: handle LinkedIn here

Future: handle Twitter here

SUBMENU HERE

Share via Chat

Copy Link