See us at Farnborough International Airshow 2026 : 3742

Plate Products and Processing Services in Oakland, CA

United Performance Metals’ Oakland, California location is focused on providing high-quality plate products and FIRSTCUT+® Processing Services.

Details

More Products & Services

Products & Services

UPM Advanced Solutions

United Performance Metals

UPM Advanced Solutions is a global provider of high-quality materials, innovative solutions, and precision supply chain services tailored to the evolving demands of advanced industries. With deep expertise in cutting-edge alloys and specialty metals, we support industries such as aerospace, space, medical, energy, and beyond, helping them drive innovation and push the boundaries of what’s possible. Our commitment to quality, reliability, and customer collaboration ensures manufacturers have access to the right materials and expertise to optimize their production processes. Whether it is powder, wire feedstock, build platforms, recoater blades, or customized supply chain solutions, UPM Advanced Solutions delivers the solutions needed to meet the most demanding applications and empowering our partners to excel.

O'Neal Industries and Affiliates

United Performance Metals

O'Neal Industries (ONI) is a family of closely related companies, all engaged in the metals industry. Providing products and services that range from steel beams and plates to specialty alloys and complex manufactured components, ONI supplies customers across a variety of industries worldwide.

First-Cut Processing Services

United Performance Metals

At United Performance Metals, we don't just sell metal, we offer FIRSTCUT+® Processing Services to further extend our commitment to you, our valued customer. FIRSTCUT+® Processing Services include additive manufacturing, cut-to-length, leveling, slitting, edging, custom rerolling, shearing, laser cutting, laser gauge measurement, water jet cutting, sawing, precision cold saw cutting, precision blanks, first stage machining, heat treating, ultra-sonic testing, boring, trepanning, deburring, and angle cutting.

United Performance Metals Linecards - Space

United Performance Metals

Industry Approvals: Boeing, GE Aircraft Engine (GT193),

Lockheed Martin, Northrop Grumman,

Pratt & Whitney LCS, SpaceX

Lockheed Martin, Northrop Grumman,

Pratt & Whitney LCS, SpaceX

United Performance Metals Linecards - Defense

United Performance Metals

Specialty Metals Solutions Center

United Performance Metals

Customer Solutions Customer Support, Market Competitive Pricing, Fast/Consistent Delivery, UPM MY Account, Material Sourcing, Inventory Management, FIRSTCUT+® Processing Services, Precision Rerolled Strip, Quality Approvals, Customer Approvals, Global Infrastructure, & Integrity.

United Performance Metals Linecards - Fasteners

United Performance Metals

United Performance Metals Linecards - Aerospace

United Performance Metals

Industry Approvals: Boeing, Eaton Aerospace, GE Aviation,

GKN Aerospace, Honeywell,

Lisi Aerospace, Lockheed Martin,

McDonnel Douglas, Northrop Grumman,

Pratt & Whitney LCS, Rolls Royce,

Toshiba ASL, Unison

GKN Aerospace, Honeywell,

Lisi Aerospace, Lockheed Martin,

McDonnel Douglas, Northrop Grumman,

Pratt & Whitney LCS, Rolls Royce,

Toshiba ASL, Unison

People

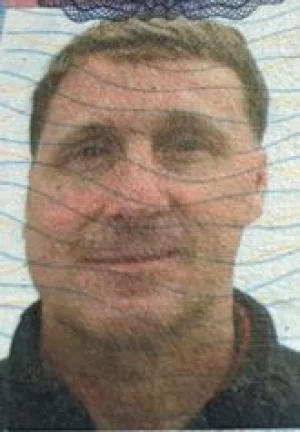

John Niehaus

United Performance Metals

Director Business Development

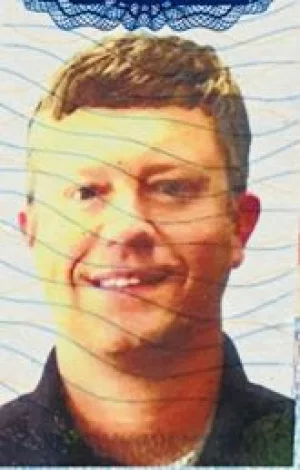

Pete Stalnaker

United Performance Metals

Regional Outside Sales Manager

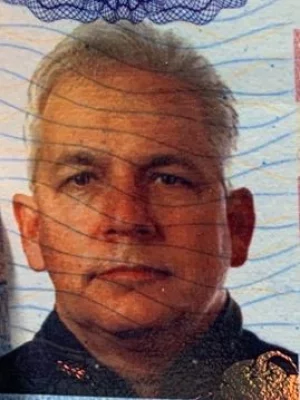

Curt Gillingham

United Performance Metals

Director of Sales

Rich Vanatsky

United Performance Metals

Director of International Business

Jeremy Pearson

United Performance Metals

International Sales/Support Team Lead

Mike Wagner

United Performance Metals

VP of Business Development

Patrick Sprague

United Performance Metals

Director of Emerging Markets

Peter Neuberger

United Performance Metals

President

Lenore Graham

United Performance Metals

Business Development Manager

Lauren Scott

United Performance Metals

Business Development Manger for Space

Max Harkavy

United Performance Metals

Business Development Manager

Katie Bland

United Performance Metals

Product Manager - Flat Roll

Jerry St. Clair

United Performance Metals

Director of Product Management

Description

United Performance Metals’ Oakland, California location is focused on providing high-quality plate products and FIRSTCUT+® Processing Services. This facility is home to grinding and precision cold saw cutting machinery that achieves precise tolerances and surface finishes. United Performance Metals Oakland, California location primarily works with stainless steel and PRODEC® grades in plate form. These products are purchased from the highest quality mills in the world and are fully certified and DFARS compliant. UPM’s Oakland facility specializes in grinding and cold sawing, where they can further process plate products to meet customers’ needs. To learn more about UPM’s plate product offerings.

Grinding - UPM’s Oakland, California branch has the capability to grind various grades of stainless steel. Standard tolerances include thickness +/- .005”, flat and parallel w/I .005” and surface finish at 63 RMS. Additionally, this location has the capacity to grind external customer-provided materials. There are two types of grinding machines used to help achieve the proper tolerance and finish: Blanchard and Double Disc. Blanchard grinding uses a vertical grinding spindle with a cylindrical grinding wheel and flat magnetic chuck to hold ferrous material to be finished. As the magnetic chuck rotates, this action helps carry the work under the sides to remove the material. The rotary motion of the grinder allows work to be loaded in a full circle so there are no end pieces. Double Disc grinding works by using abrasive wheels on opposite sides of each other to grind and remove equal amounts from both sides of material. This process generally produces the highest level of flatness and parallelism on opposing surfaces and is typically used for high productivity jobs. To learn more about UPM’s grinding services.

Precision Cold Saw Cutting - UPM’s Cold saw cutting virtually eliminates the heat affected zones often incurred as part of the plasma cutting process and minimizes labor time and expense. Standard tolerances include 3/16" - 1 3/4" +/- .060 - .000 and 2" and thicker +/- .125 - .000. A cold saw is a circular saw with a toothed saw blade that keeps the primary material cool. The chips that are cut away from the metal absorb the heat, thus transferring it away from the material being cut as well as the cutting blade. United Performance Metals utilizes superior grade, precision tungsten carbide tips specifically suited for customer applications. To learn more about UPM’s precision cold saw cutting.

Grinding - UPM’s Oakland, California branch has the capability to grind various grades of stainless steel. Standard tolerances include thickness +/- .005”, flat and parallel w/I .005” and surface finish at 63 RMS. Additionally, this location has the capacity to grind external customer-provided materials. There are two types of grinding machines used to help achieve the proper tolerance and finish: Blanchard and Double Disc. Blanchard grinding uses a vertical grinding spindle with a cylindrical grinding wheel and flat magnetic chuck to hold ferrous material to be finished. As the magnetic chuck rotates, this action helps carry the work under the sides to remove the material. The rotary motion of the grinder allows work to be loaded in a full circle so there are no end pieces. Double Disc grinding works by using abrasive wheels on opposite sides of each other to grind and remove equal amounts from both sides of material. This process generally produces the highest level of flatness and parallelism on opposing surfaces and is typically used for high productivity jobs. To learn more about UPM’s grinding services.

Precision Cold Saw Cutting - UPM’s Cold saw cutting virtually eliminates the heat affected zones often incurred as part of the plasma cutting process and minimizes labor time and expense. Standard tolerances include 3/16" - 1 3/4" +/- .060 - .000 and 2" and thicker +/- .125 - .000. A cold saw is a circular saw with a toothed saw blade that keeps the primary material cool. The chips that are cut away from the metal absorb the heat, thus transferring it away from the material being cut as well as the cutting blade. United Performance Metals utilizes superior grade, precision tungsten carbide tips specifically suited for customer applications. To learn more about UPM’s precision cold saw cutting.

Share

Recent Chats

Share via email

Future: handle WhatsApp here

Future: handle LinkedIn here

Future: handle Twitter here

SUBMENU HERE

Share via Chat

Copy Link