Quality Approvals

AS9100D with ISO 9001, AS13100, NADCAP AC7116, GE Aircraft Engine (GT193), GE S422

Nickel Alloys, Titanium, Stainless Steel, Cobalt Alloys

Aerospace Grade Materials: Nickel Alloys, Titanium, Stainless Steel, Cobalt Alloys

UPM Advanced Solutions

UPM also proudly serves the additive manufacturing industry through UPM Advanced Solutions

14 Service Centers Worldwide

UPM is headquartered in Cincinnati, Ohio and maintains 14 service centers worldwide

UNITED PERFORMANCE METALS

See us at Farnborough International Airshow 2026 · Booth: 3742

United Performance Metals (UPM) is a specialty metals solutions center serving the aerospace industry with high-performance materials essential for aircraft manufacturing and maintenance offering titanium, nickel alloys, stainless steel and cobalt alloys in various forms.

Hamilton, Ohio, United States

Aerospace, Healthcare, Defense & Security, Oil · Gas · Energy

Products & Services

People

News

Other

About

Connect with us at

Products & Services

United Performance Metals Linecards - Fasteners

United Performance Metals

United Performance Metals Linecards - Aerospace

United Performance Metals

Industry Approvals: Boeing, Eaton Aerospace, GE Aviation,

GKN Aerospace, Honeywell,

Lisi Aerospace, Lockheed Martin,

McDonnel Douglas, Northrop Grumman,

Pratt & Whitney LCS, Rolls Royce,

Toshiba ASL, Unison

GKN Aerospace, Honeywell,

Lisi Aerospace, Lockheed Martin,

McDonnel Douglas, Northrop Grumman,

Pratt & Whitney LCS, Rolls Royce,

Toshiba ASL, Unison

First-Cut Processing Services

United Performance Metals

At United Performance Metals, we don't just sell metal, we offer FIRSTCUT+® Processing Services to further extend our commitment to you, our valued customer. FIRSTCUT+® Processing Services include additive manufacturing, cut-to-length, leveling, slitting, edging, custom rerolling, shearing, laser cutting, laser gauge measurement, water jet cutting, sawing, precision cold saw cutting, precision blanks, first stage machining, heat treating, ultra-sonic testing, boring, trepanning, deburring, and angle cutting.

O'Neal Industries and Affiliates

United Performance Metals

O'Neal Industries (ONI) is a family of closely related companies, all engaged in the metals industry. Providing products and services that range from steel beams and plates to specialty alloys and complex manufactured components, ONI supplies customers across a variety of industries worldwide.

United Performance Metals Linecards - Space

United Performance Metals

Industry Approvals: Boeing, GE Aircraft Engine (GT193),

Lockheed Martin, Northrop Grumman,

Pratt & Whitney LCS, SpaceX

Lockheed Martin, Northrop Grumman,

Pratt & Whitney LCS, SpaceX

UPM Advanced Solutions

United Performance Metals

UPM Advanced Solutions is a global provider of high-quality materials, innovative solutions, and precision supply chain services tailored to the evolving demands of advanced industries. With deep expertise in cutting-edge alloys and specialty metals, we support industries such as aerospace, space, medical, energy, and beyond, helping them drive innovation and push the boundaries of what’s possible. Our commitment to quality, reliability, and customer collaboration ensures manufacturers have access to the right materials and expertise to optimize their production processes. Whether it is powder, wire feedstock, build platforms, recoater blades, or customized supply chain solutions, UPM Advanced Solutions delivers the solutions needed to meet the most demanding applications and empowering our partners to excel.

United Performance Metals Linecards - Defense

United Performance Metals

Specialty Metals Solutions Center

United Performance Metals

Customer Solutions Customer Support, Market Competitive Pricing, Fast/Consistent Delivery, UPM MY Account, Material Sourcing, Inventory Management, FIRSTCUT+® Processing Services, Precision Rerolled Strip, Quality Approvals, Customer Approvals, Global Infrastructure, & Integrity.

People

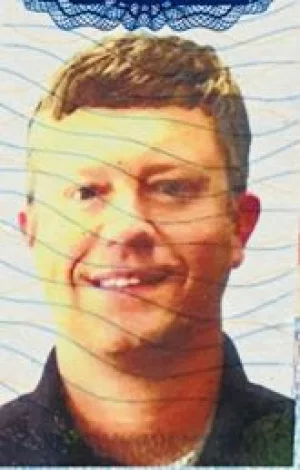

Curt Gillingham

United Performance Metals

Director of Sales

Curt Gillingham

United Performance Metals

Director of Sales

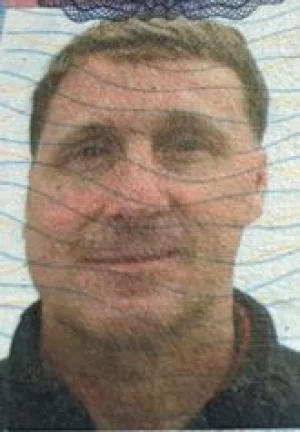

Doyle Carpenter

United Performance Metals

Business Development Manager

Jeffrey Liesch

United Performance Metals

Chief Financial Officer

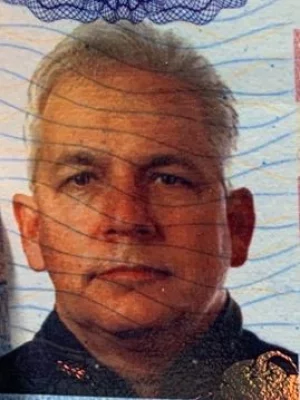

Jeremy Pearson

United Performance Metals

International Sales/Support Team Lead

Jerry St. Clair

United Performance Metals

Director of Product Management

Jody Seither

United Performance Metals

Marketing Coordinator

Farnborough International Airshow 2026

John Niehaus

United Performance Metals

Director Business Development

Katie Bland

United Performance Metals

Product Manager - Flat Roll

Lauren Scott

United Performance Metals

Business Development Manger for Space

Lenore Graham

United Performance Metals

Business Development Manager

Max Harkavy

United Performance Metals

Business Development Manager

Mike Wagner

United Performance Metals

VP of Business Development

Patrick Sprague

United Performance Metals

Director of Emerging Markets

Pete Stalnaker

United Performance Metals

Regional Outside Sales Manager

Peter Neuberger

United Performance Metals

President

Rich Vanatsky

United Performance Metals

Director of International Business

Tiffany Walker

United Performance Metals

Marketing Manager

Farnborough International Airshow 2026

News

UNITED PERFORMANCE METALS ANNOUNCES ACQUISITION OF FABRISONIC LLC

United Performance Metals (UPM), an O’Neal Industries affiliate company, is pleased to announce the acquisition of Fabrisonic LLC, a small tech startup dedicated to inspiring the world with new ways of making materials through its patented process, enabling customers to create concepts impossible with traditional manufacturing. This strategic acquisition will enhance UPM’s capabilities in advanced manufacturing and expand its portfolio of innovative solutions.

Fabrisonic, headquartered in Columbus, Ohio, was a division of EWI, a renowned leader in advanced manufacturing technologies, before becoming an independent company in 2011. Specializing in metal fabrication and innovation, Fabrisonic developed patented processes to create unique metal materials for industries such as aerospace, defense, space, and automotive. Their technology allows for the joining of dissimilar metals without metallurgical mismatch issues, enabling the creation of high-performance components that increase heat transfer rates, reduce weight, and allow for the embedding of various sensors, amongst a wide variety of unique applications. For more information visit www.fabrisonic.com.

“I am proud of what our team has accomplished and am excited about the future,” said Henry Cialone, Fabrisonic’s Board Chairman and CEO of EWI. “This acquisition opens up new opportunities for both Fabrisonic and our customers, and I look forward to seeing what we can achieve together moving forward.”

United Performance Metals is a global specialty metals solutions center serving customers in a variety of industries offering a full line of high-performance metals and alloys, FIRSTCUT+® Processing Services, quality approvals, and custom supply chain solutions. Fabrisonic will join UPM under the specialty processing facilities that include Precision Thin Strip in Wallingford, CT; UPM Advanced Solutions in Cincinnati, OH; and Precision Cold Saw Cutting and Grinding in Oakland, CA. These locations help provide value-added processing to specialty metals to help UPM’s innovative customers change the world.

“We are thrilled to welcome Fabrisonic to the United Performance Metals family,” said Peter Neuberger, President and CEO of United Performance Metals. “Their cutting-edge technology and expertise will significantly bolster our capabilities to create unique materials to support our innovative manufacturing customers.”

“This is a significant step forward for Fabrisonic,” said Jason Riley, General Manager of Fabrisonic. “Joining the United Performance Metals family of companies will enable Fabrisonic to leverage greater resources and expanded capabilities. This will allow us to increase our market reach and continue to bring novel solutions to our customers. Kudos to our incredible team of engineers, both past and present, for getting us to this point. We have a bright future ahead and are excited for this next step.”

This acquisition marks a significant milestone for United Performance Metals, reinforcing its commitment to technological advancement and industry leadership. The company is eager to leverage Fabrisonic’s innovative technology to deliver superior solutions and drive transformative progress for its clients and partners.

Fabrisonic, headquartered in Columbus, Ohio, was a division of EWI, a renowned leader in advanced manufacturing technologies, before becoming an independent company in 2011. Specializing in metal fabrication and innovation, Fabrisonic developed patented processes to create unique metal materials for industries such as aerospace, defense, space, and automotive. Their technology allows for the joining of dissimilar metals without metallurgical mismatch issues, enabling the creation of high-performance components that increase heat transfer rates, reduce weight, and allow for the embedding of various sensors, amongst a wide variety of unique applications. For more information visit www.fabrisonic.com.

“I am proud of what our team has accomplished and am excited about the future,” said Henry Cialone, Fabrisonic’s Board Chairman and CEO of EWI. “This acquisition opens up new opportunities for both Fabrisonic and our customers, and I look forward to seeing what we can achieve together moving forward.”

United Performance Metals is a global specialty metals solutions center serving customers in a variety of industries offering a full line of high-performance metals and alloys, FIRSTCUT+® Processing Services, quality approvals, and custom supply chain solutions. Fabrisonic will join UPM under the specialty processing facilities that include Precision Thin Strip in Wallingford, CT; UPM Advanced Solutions in Cincinnati, OH; and Precision Cold Saw Cutting and Grinding in Oakland, CA. These locations help provide value-added processing to specialty metals to help UPM’s innovative customers change the world.

“We are thrilled to welcome Fabrisonic to the United Performance Metals family,” said Peter Neuberger, President and CEO of United Performance Metals. “Their cutting-edge technology and expertise will significantly bolster our capabilities to create unique materials to support our innovative manufacturing customers.”

“This is a significant step forward for Fabrisonic,” said Jason Riley, General Manager of Fabrisonic. “Joining the United Performance Metals family of companies will enable Fabrisonic to leverage greater resources and expanded capabilities. This will allow us to increase our market reach and continue to bring novel solutions to our customers. Kudos to our incredible team of engineers, both past and present, for getting us to this point. We have a bright future ahead and are excited for this next step.”

This acquisition marks a significant milestone for United Performance Metals, reinforcing its commitment to technological advancement and industry leadership. The company is eager to leverage Fabrisonic’s innovative technology to deliver superior solutions and drive transformative progress for its clients and partners.

28 May 2025

UPM Advanced Solutions Partners with Carpenter Additive for Powder Supply

To better serve the additive manufacturing community, UPM Advanced Solutions is now the preferred powder distributor for Carpenter Additive. This partnership strengthens Carpenter’s reach by enabling UPM Advanced Solutions to support transactional powder business with expert service and flexible ordering. UPM Advanced Solutions offers fast, reliable delivery—including same-day shipping on in-stock materials—ensuring customers experience shorter lead times and greater convenience. As Carpenter’s trusted distribution partner, UPM Advanced Solutions is committed to helping grow the powder market and making high-performance additive materials more accessible.

UPM Advanced Solutions will be stocking high-quality Carpenter powder that is used for Laser Powder Bed Fusion (LPBF), Direct Energy Deposition (DED), and Electron Beam Melting (EBM). These materials are commonly used in the aerospace, defense, space, medical, and energy industries, as well as other industrial markets. Below is a breakdown of the new powders and some of their key features and benefits:

- Inconel 625: Inconel 625 offers outstanding high temperature strength, great corrosion resistance, and high fatigue and creep rupture strength. This material is commonly used in aerospace, oil & gas, and power generation applications.

- Inconel 718: Inconel 718 has high temperature strength and fatigue resistance, lending it to a wide range of applications including aerospace, space, defense, oil & gas, and other industries where high temperature and strength are needed.

- AlSi10Mg: This aluminum alloy powder is known for its lightweight nature, corrosion resistance, thermal conductivity, and high strength-to-weight ratio. It is a versatile material that is used in various industries, particularly aerospace and automotive.

- Stainless 316: Stainless 316 offers excellent corrosion resistance, strength, ductility, and toughness, as well a great high-temperature performance. In additive manufacturing, this powder is typically used for aerospace and medical applications.

- Stainless 15-5: This powder poses high strength and hardness, even at elevated temperatures, making it suitable for demanding applications including aerospace, nuclear, and other high energy industries.

- M300: With high strength, hardness, and wear resistance, tool steel 300 is able to be used in a range of applications, specifically tooling and die casting.

- Ti-64: This material offers high strength, low density, excellent corrosion resistance, and biocompatibility, making it suitable for medical applications.

- Grade 23: This titanium grade includes excellent biocompatibility and enhanced mechanical properties, making it a top contender in the medical industry for implants and surgical instruments.

- Hastelloy HX: This nickel-based powder offers great tensile strength and high temperature performance. Hastelloy HX is used in the aerospace, power generation, and alternative energy industries.

- GrCop42: This material displays high thermal conductivity, excellent creep resistance, and the ability to maintain strength at high temperatures, making it suitable for high heat application including space and aerospace.

- CCM: Due to its excellent mechanical properties, corrosion resistance, and biocompatibility, CCM is commonly used in medical applications and aerospace components.

- CCM MC: This material offers high strength, corrosion resistance, wear resistance, and biocompatibility. Due to these key features, CCM MC is used in the power generation and medical industries.

At UPM Advanced Solutions, we are here to be your one-stop shop for additive solutions, with build plates, powder, feedstock, and other consumables, as well as customizable solutions, post print processing, and value chain management. As a global provider, our goal is to achieve same-day responses, next-day shipments, and quick turnarounds, making sure that we have the proper inventory on hand. We are here to help any customer find the powder they are looking for, even if it is not currently stocked and readily available.

UPM Advanced Solutions will be stocking high-quality Carpenter powder that is used for Laser Powder Bed Fusion (LPBF), Direct Energy Deposition (DED), and Electron Beam Melting (EBM). These materials are commonly used in the aerospace, defense, space, medical, and energy industries, as well as other industrial markets. Below is a breakdown of the new powders and some of their key features and benefits:

- Inconel 625: Inconel 625 offers outstanding high temperature strength, great corrosion resistance, and high fatigue and creep rupture strength. This material is commonly used in aerospace, oil & gas, and power generation applications.

- Inconel 718: Inconel 718 has high temperature strength and fatigue resistance, lending it to a wide range of applications including aerospace, space, defense, oil & gas, and other industries where high temperature and strength are needed.

- AlSi10Mg: This aluminum alloy powder is known for its lightweight nature, corrosion resistance, thermal conductivity, and high strength-to-weight ratio. It is a versatile material that is used in various industries, particularly aerospace and automotive.

- Stainless 316: Stainless 316 offers excellent corrosion resistance, strength, ductility, and toughness, as well a great high-temperature performance. In additive manufacturing, this powder is typically used for aerospace and medical applications.

- Stainless 15-5: This powder poses high strength and hardness, even at elevated temperatures, making it suitable for demanding applications including aerospace, nuclear, and other high energy industries.

- M300: With high strength, hardness, and wear resistance, tool steel 300 is able to be used in a range of applications, specifically tooling and die casting.

- Ti-64: This material offers high strength, low density, excellent corrosion resistance, and biocompatibility, making it suitable for medical applications.

- Grade 23: This titanium grade includes excellent biocompatibility and enhanced mechanical properties, making it a top contender in the medical industry for implants and surgical instruments.

- Hastelloy HX: This nickel-based powder offers great tensile strength and high temperature performance. Hastelloy HX is used in the aerospace, power generation, and alternative energy industries.

- GrCop42: This material displays high thermal conductivity, excellent creep resistance, and the ability to maintain strength at high temperatures, making it suitable for high heat application including space and aerospace.

- CCM: Due to its excellent mechanical properties, corrosion resistance, and biocompatibility, CCM is commonly used in medical applications and aerospace components.

- CCM MC: This material offers high strength, corrosion resistance, wear resistance, and biocompatibility. Due to these key features, CCM MC is used in the power generation and medical industries.

At UPM Advanced Solutions, we are here to be your one-stop shop for additive solutions, with build plates, powder, feedstock, and other consumables, as well as customizable solutions, post print processing, and value chain management. As a global provider, our goal is to achieve same-day responses, next-day shipments, and quick turnarounds, making sure that we have the proper inventory on hand. We are here to help any customer find the powder they are looking for, even if it is not currently stocked and readily available.

28 May 2025

Plate Products and Processing Services in Oakland, CA

United Performance Metals’ Oakland, California location is focused on providing high-quality plate products and FIRSTCUT+® Processing Services. This facility is home to grinding and precision cold saw cutting machinery that achieves precise tolerances and surface finishes. United Performance Metals Oakland, California location primarily works with stainless steel and PRODEC® grades in plate form. These products are purchased from the highest quality mills in the world and are fully certified and DFARS compliant. UPM’s Oakland facility specializes in grinding and cold sawing, where they can further process plate products to meet customers’ needs. To learn more about UPM’s plate product offerings.

Grinding - UPM’s Oakland, California branch has the capability to grind various grades of stainless steel. Standard tolerances include thickness +/- .005”, flat and parallel w/I .005” and surface finish at 63 RMS. Additionally, this location has the capacity to grind external customer-provided materials. There are two types of grinding machines used to help achieve the proper tolerance and finish: Blanchard and Double Disc. Blanchard grinding uses a vertical grinding spindle with a cylindrical grinding wheel and flat magnetic chuck to hold ferrous material to be finished. As the magnetic chuck rotates, this action helps carry the work under the sides to remove the material. The rotary motion of the grinder allows work to be loaded in a full circle so there are no end pieces. Double Disc grinding works by using abrasive wheels on opposite sides of each other to grind and remove equal amounts from both sides of material. This process generally produces the highest level of flatness and parallelism on opposing surfaces and is typically used for high productivity jobs. To learn more about UPM’s grinding services.

Precision Cold Saw Cutting - UPM’s Cold saw cutting virtually eliminates the heat affected zones often incurred as part of the plasma cutting process and minimizes labor time and expense. Standard tolerances include 3/16" - 1 3/4" +/- .060 - .000 and 2" and thicker +/- .125 - .000. A cold saw is a circular saw with a toothed saw blade that keeps the primary material cool. The chips that are cut away from the metal absorb the heat, thus transferring it away from the material being cut as well as the cutting blade. United Performance Metals utilizes superior grade, precision tungsten carbide tips specifically suited for customer applications. To learn more about UPM’s precision cold saw cutting.

Grinding - UPM’s Oakland, California branch has the capability to grind various grades of stainless steel. Standard tolerances include thickness +/- .005”, flat and parallel w/I .005” and surface finish at 63 RMS. Additionally, this location has the capacity to grind external customer-provided materials. There are two types of grinding machines used to help achieve the proper tolerance and finish: Blanchard and Double Disc. Blanchard grinding uses a vertical grinding spindle with a cylindrical grinding wheel and flat magnetic chuck to hold ferrous material to be finished. As the magnetic chuck rotates, this action helps carry the work under the sides to remove the material. The rotary motion of the grinder allows work to be loaded in a full circle so there are no end pieces. Double Disc grinding works by using abrasive wheels on opposite sides of each other to grind and remove equal amounts from both sides of material. This process generally produces the highest level of flatness and parallelism on opposing surfaces and is typically used for high productivity jobs. To learn more about UPM’s grinding services.

Precision Cold Saw Cutting - UPM’s Cold saw cutting virtually eliminates the heat affected zones often incurred as part of the plasma cutting process and minimizes labor time and expense. Standard tolerances include 3/16" - 1 3/4" +/- .060 - .000 and 2" and thicker +/- .125 - .000. A cold saw is a circular saw with a toothed saw blade that keeps the primary material cool. The chips that are cut away from the metal absorb the heat, thus transferring it away from the material being cut as well as the cutting blade. United Performance Metals utilizes superior grade, precision tungsten carbide tips specifically suited for customer applications. To learn more about UPM’s precision cold saw cutting.

28 May 2025

Connect with us at

About

United Performance Metals (UPM) is a specialty metals solutions center serving the aerospace industry with high-performance materials essential for aircraft manufacturing and maintenance.

UPM offers an extensive inventory of titanium, nickel alloys, stainless steel and cobalt alloys in various forms with both DFARS and non-DFARS designations.

Our comprehensive FIRSTCUT+® Processing Services include cut-to-length, leveling, slitting, edging, shearing, laser cutting, water jet cutting, sawing, precision cold saw cutting, and more.

UPM also proudly serves the additive manufacturing industry through UPM Advanced Solutions by providing high-quality materials, cutting-edge alloys, and customized supply chain solutions – ranging from powder, feedstock, and build platforms to recoater blades and post-print processing – empowering industries like aerospace to drive innovation and optimize production.

Our quality system approvals include AS9100D with ISO 9001:2015; NADCAP AS7116 and GE S422 laser cutting approvals; and industry approvals from GE Aircraft Engine (GT 193), Pratt & Whitney (LCS-Appendix 36 and SQAR), and many other OEM approvals.

UPM is headquartered in Cincinnati, Ohio and maintains 14 service centers worldwide. For more information, visit www.upmet.com.

UPM offers an extensive inventory of titanium, nickel alloys, stainless steel and cobalt alloys in various forms with both DFARS and non-DFARS designations.

Our comprehensive FIRSTCUT+® Processing Services include cut-to-length, leveling, slitting, edging, shearing, laser cutting, water jet cutting, sawing, precision cold saw cutting, and more.

UPM also proudly serves the additive manufacturing industry through UPM Advanced Solutions by providing high-quality materials, cutting-edge alloys, and customized supply chain solutions – ranging from powder, feedstock, and build platforms to recoater blades and post-print processing – empowering industries like aerospace to drive innovation and optimize production.

Our quality system approvals include AS9100D with ISO 9001:2015; NADCAP AS7116 and GE S422 laser cutting approvals; and industry approvals from GE Aircraft Engine (GT 193), Pratt & Whitney (LCS-Appendix 36 and SQAR), and many other OEM approvals.

UPM is headquartered in Cincinnati, Ohio and maintains 14 service centers worldwide. For more information, visit www.upmet.com.

Add Attachment

Share

Recent Chats

Share via email

Future: handle WhatsApp here

Future: handle LinkedIn here

Future: handle Twitter here

SUBMENU HERE

Share via Chat

Copy Link