JetZero Takes The Wraps Off Blended Wing Body Development Plans

Details

More Products & Services

Products & Services

Home - Aviation Group Marketing

Aviation Week Network

120 data points on over 156,000 commercial and business aviation aircraft, including military transports. Discover the most trustworthy resource for the complete aircraft history, plus ad hoc reports, month-over-month trend analysis and details on expected deliveries through 2050.

Aerospace | Aviation Week Network

Aviation Week Network

https://aviationweek.com/themes/custom/particle/dist/app-drupal/assets/awn-logo.svg

People

Andrea Rossi Prudente

Aviation Week Network

Anthony Lim

Aviation Week Network

Sales director

Becca Balmes

Aviation Week Network

Belinda Tan

Aviation Week Network

Brian Everstine

Aviation Week Network

Editor

Eddie Krankowski

Aviation Week Network

Assistant Manager, Tradeshows

erving dockery

Aviation Week Network

Lisa Tan

Aviation Week Network

Senior Marketing Manager

Mark Thomas

Aviation Week Network

Description

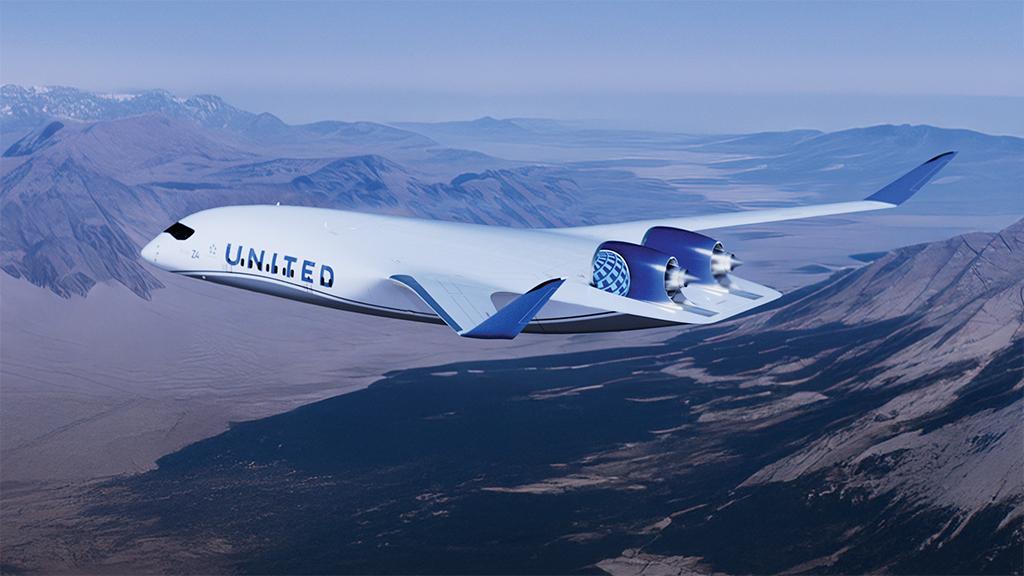

A little more than two years after JetZero revealed ambitious plans to challenge the Airbus-Boeing air transport duopoly by developing a blended wing body (BWB) airliner, the California company remains on track to fly a full-scale demonstrator by late 2027.

In development under a $235 million cost-sharing U.S. Air Force contract awarded in 2023, the dual-role demonstrator is intended to provide the basis for the follow-on development of a new-generation military tanker-transport and a more efficient midmarket airliner.The demonstrator's design review is finalizedGreensboro, North Carolina, is selected for serial production

The startup acknowledges the huge task of building the demonstrator—an imposing twin-engine design with the same wingspan as a Boeing B-52. However, it is development of the proposed Z4 follow-on production model that begs the question: Can JetZero really pull this off?

The answer is an unequivocal “yes,” according to co-founder and CEO Tom O'Leary, who says JetZero is winning the battle for credibility by taking a pragmatic approach to testing, development, certification and production. Underpinning this strategy is the plan to use Part 25-certified and commercial-off-the-shelf components for about 80% of the aircraft's systems and equipment.

But reaching this stage has not been easy. Despite the potential for fuel-efficiency gains of up to 50% compared with current tube-and-wing designs and a 200-250-passenger midmarket sector largely ignored by Airbus and Boeing, JetZero's initial business plans were met with skepticism, O'Leary says.

Potential investors and supporters “would be looking at us and say: ‘What are you guys, like eight people? You do realize there's a global duopoly, right?' ” he recalls.

The challenge was “daunting, but not impossible,” he says. “So how did we turn that impossibility into inevitability? We went to the Air Force, and NASA helped us. They walked us into the Air Force, which was looking for a 21st-century airplane for a 21st-century problem, which is the tyranny of distance in the Pacific. The Air Force said: ‘We'd like to see a full-scale demonstration of this because that capability could really be a game-changer.' ”

Since the initial Air Force contract award in August 2023, JetZero's project has continued to gather momentum. Bolstered in April by the addition of United Airlines to the growing list of publicly named carriers—alongside Alaska Airlines and Delta Air Lines—willing to reveal an investment in the project, the company has focused on building a comprehensive group of industry suppliers and recruiting a team of experts covering everything from structures and systems to certification and manufacturing.

“We have over $300 million that's committed to the program,” O'Leary says. “We've spent barely half of what's been committed. To tap into all of the more than $150 million remaining, a lot of which comes from the Air Force, we do have financial milestones that we need to hit, and we're in the middle of raising our Series B funding to achieve those goals. That's going very well because we have a demand signal that's very strong and very clear.”

Operating in stealth mode for the first three years since its founding in 2020 by BWB veteran Mark Page and former Tesla and Beta Technologies executive O'Leary, the company expanded in 2024 into its current 285,000-ft.2, seven-building headquarters in Long Beach. The site is home to JetZero's business operations, design team, cabin lab, fabrication shop, scale-model program and aero labs—including a flying qualities lab, iron-bird systems test rig and integrated test facility.

Manufacturing of the demonstrator is underway at Northrop Grumman's Scaled Composites facility in Mojave, California. Serial production of the Z4 BWB will take place at a manufacturing and final assembly site in Greensboro, North Carolina. The site, which was announced in June after an exhaustive nationwide competition among 24 locations in 13 states, forms part of a $4.7 billion investment plan designed to create 14,500 regional aerospace jobs.

From a hardware perspective for the demonstrator, “we are much more advanced than you think,” says Florentina Viscotchi, head of engineering and formerly head of the Airbus A220 corporate jet program. Work has begun to lay out the composite structure of the cockpit, while the fuel tanks already are built. Among other components and assemblies under development, she adds: “The wing test article has been built, and now we are on the path to building that jig so we can build the final shape of the wing.” JetZero tests interoperability of electrical and electronic systems, including flight control computers and sidesticks, in its Integration Test Facility lab. Credit: JetZero

Design of the production version is underway in parallel, aided by input from JetZero's airline working group. “They give us feedback, and we take that into account in our product design. As a matter of fact, very soon, we will have a full baseline definition for that product, and that is an essential piece from which we continue driving trade studies,” Viscotchi says.

The working group's input already has informed meaningful changes to the configuration of both the demonstrator and production unit. For example, when JetZero completed a critical design review (CDR) of the demonstrator in May, it incorporated key changes to simplify the landing gear configuration made at the behest of the group.

The revised gear arrangement sees the main landing gear legs moved forward and a conventional design replacing the originally proposed articulating pivot-gear nose leg. JetZero says the changes, which will be validated in upcoming wind tunnel tests, will not delay flight tests of the proof-of-concept BWB aircraft in late 2027.

Page conceived the pivot-gear concept, originally called the pivot piston, to solve a conundrum facing BWB designs. Due to their short moment arm in pitch, blended-wing configurations require the main landing gear to be near the center of gravity (CG) for takeoff rotation. Although this improves low-speed pitch authority, the internal area used for stowage of the main and nose gears dramatically increases the overall depth of the aircraft, making it too big and heavy for the single-aisle or midsize market.

By pivoting the nose gear, the design enabled the main gear to be moved farther aft, behind the cabin-pressure vessel rather than beneath it, freeing up space to allow a single deck configuration. On takeoff, the nose gear is designed to pivot and extend, raising the nose and creating extra lift from the body, which allows the aircraft to rotate around a “virtual” CG with minimal elevon download forces.

But the airlines within its advisory group wanted a simpler design, JetZero President and Chief Operating Officer Dan Da Silva says. “The more we talked to the FAA and the airlines, everybody was ‘derisk, derisk, derisk,'” he notes. “So we looked at moving the main gear forward, closer to the CG of the airplane.”

The additional lift from the body still “will enable liftoff speed to be slower, reducing demand for high takeoff thrust,” says the head of flight sciences, Hsin-Yi Yen. He explains that the initial design will meet its performance goals with relatively small trailing-edge flaps and without the need for leading-edge high-lift slats.

Although the new configuration will require an internal redesign for the production model, JetZero faces fewer gear-retraction design restrictions on the demonstrator, which has been designed purely for proving the BWB's aerodynamic qualities and does not carry any payload. The “Franken-demonstrator” will incorporate systems and components from several existing aircraft, including main landing gear from a McDonnell Douglas MD-11, nose gear and Pratt & Whitney PW2040 engines from a Boeing 757 and a hybrid electrical system combining elements from a Boeing 767 and Boeing C-17.

“We're iterating on the production airplane design,” Da Silva says. “We still want to keep the same thickness, and we have a lot of potential to move up the passenger floor and create space underneath. So it is still a single deck, but it does have a half-deck under it, which could fit the landing gear as well as LD3-45 containers.” Such cargo containers are used in the Airbus A320/A321.

The pivot nose gear remains an option for future proposed follow-on Z3-family variants in the A320-Boeing 737 single-aisle replacement class. “We may go back to that design on a smaller-scale airplane, but at the size that we're at [with the Z4,] the articulating nose gear was very big and complex and heavy,” Da Silva says. “We had a very workable design, and it works really well. We're about to test another scale version of it.”

Creation of additional lower deck space also may help to answer other questions posed by the working group. “Airlines have given us feedback because in the single-deck configuration: You must load bags into the ‘armpit' of the airplane, and you can't load it all from one side. You need to have two loaders,” Da Silva says. “From an airline ground-operations perspective, it is a little bit more of a challenge. So they tasked us to find different solutions.”

Further details of the redesign will be unveiled after completion of the CDR. Operators “will be pleased with the outcome of that decision,” Viscotchi says. “I can't tell you more at this point, but we do have that configuration nailed down. This is the configuration that will be used for the demonstrator, as well as for the product.”

JetZero also is discussing propulsion options for the production version with engine suppliers including Pratt & Whitney, which is providing PW2040s for the demonstrator. BWB engine concepts also were presented by GE Aerospace-CFM International, Rolls-Royce and Kratos-owned FTT at JetZero's recent airline advisory group meeting.

Although Pratt appears to be in a leading position to supply the powerplant for the initial production aircraft, Viscotchi says the goal is to offer a choice of engines. “We've also heard loud and clear from those airlines that a dual-engine source is a very important item to consider,” she says. Citing her previous experience working on the A220, which is exclusively powered by Pratt, Viscotchi notes that offering a choice “allows me to keep that guy on their toes.”

JetZero is asking engine-makers for propulsion systems that are optimized for top-of-climb thrust to suit a balanced power demand from takeoff to cruise altitudes of up to 45,000 ft. This, in turn, calls for engines with lower bypass ratios than the latest generation of turbofans, in service ones, in development or ones under study for aircraft in the 2030s.

Although seemingly counterintuitive in an age of ever-increasing bypass ratios, the company says a lower bypass better meets the aircraft's performance goals while achieving the design limit of 80% maximum continuous thrust. Any noise and cruise efficiency penalties are compensated for by airframe shielding and the BWB's lift-drag performance, JetZero says.

“A lower-bypass-ratio engine works better for us,” Da Silva says, emphasizing that the requirement is “not a low bypass, but lower.” The target is in the 6.5:1-8:1 bypass-ratio range. “That's perfectly fine,” he notes. “We don't need to go to 11:1-13:1, which is great for mid-30s cruise [35,000 ft.] and maybe a maximum takeoff weight [MTOW] of 180,000-200,000 lb. We are going be around 280,000-290,000 lb. MTOW on the production airplane, and we want to fly at 45,000 ft., so more like a Gulfstream.”

The Z4 engines will be the first commercial airliner turbofans to be mounted over-wing since the Rolls-Royce-Snecma M45 on the VFW614 regional jet. While both the VFW614 and the more recently developed GE Aerospace-Honda HF120-powered HA-420 HondaJet business aircraft were designed with a single strut mount, the Z4 engine will be supported on a split pylon with a gap between the struts for boundary layer diversion.

The semiburied nacelles are designed to prevent inlet distortion by channeling the boundary layer beneath the engine. Although some of the boundary layer still may be ingested at high thrust and low airspeed, the exit of the diverter is positioned below the nozzle, where it will draw a vacuum, enabling the diverter intake flow rate to match that of the engine inlet.

Final design release for the nacelle is scheduled for mid-2026, and the finished product is expected to be ready for installation on the demonstrator in early 2027. JetZero says it also is working with Pratt and the airline group on methods for servicing the engine on the Z4. Large side-of-body structural members, represented in the Z4 cabin mockup, indicate the interface area between the noncylindrical cabin pressure vessel and the wing. Credit: Guy Norris/AW&ST

Through 2024 and early 2025, the focus for aerodynamic testing has been on a series of subscale aircraft, data from which continues to be fed into the flying qualities lab for flight controls development. Initial work through the first part of this year included tests of Subscale Vehicle (SV) 1, in which the first 6.25%-scale BWB model was attached to the back of a truck for open-air, high-speed runs.

“It's like a moving wind tunnel,” Da Silva says. “It allows us to do a lot of the tests that you would do in a wind tunnel by running a truck up and down the runway. Long Beach Airport has been very collaborative with us. They shut down a taxiway, and we can go up and down at 60-plus mph with a big, 11-ft.-wingspan airplane attached to the back of a pickup truck.”

JetZero's decision to refocus on the smaller SV test series comes after the loss of the larger and more expensive 12.5%-scale air vehicle (AV-1) in a battery fire following its first flight in June 2024. AV-1 was designed to inform the development of flight controls. “We can do all that in a 6.25% model at one-eighth the cost,” Da Silva says. “So that allows us to build multiple models, experiment as we go and fly at a higher tempo.

“We're targeting about mid-July for when we feel that we have all the control laws and configuration firmed up on the SV program,” he continues. “Then we can choose to fly the second 12.5%-scale vehicle, AV-2, or not.”

Results will be incorporated into the overall aerodynamic database, with contributions coming from further low- and high-speed wind tunnel tests planned for this year and early in 2026.

Aerodynamic data from refined computational fluid dynamics analysis scheduled for the third quarter of 2025 also will be fed into the flying qualities lab. This will be augmented with results from the high-speed wind tunnel work scheduled for early next year, leading to the planned completion of flight control law tests before mid-2026.

The flying qualities lab enables rapid prototyping of flight control software and “ensures we can develop a very safe pilot-in-the-loop fly-by-wire flight control system,” control law engineer Gerald Arzoumanian says. “By ‘safe,' in this case we mean to have precise handling qualities and low pilot workload in normal or abnormal conditions.”

Veteran flight control law developer and test pilot Scott Buethe, who will fly the demonstrator along with former Virgin Orbit test pilot Mathew Stannard, says the BWB flight control architecture incorporates several special features. “We've designed the flight control system so that you can introduce side slip, and it basically just keeps the wings level for you,” Buethe says. “So we decoupled yaw and roll.”

Although tailless in the conventional sense, the BWB will have wingtip-mounted vertical rudders, two sets of multisegment ailerons inboard and outboard and elevators mounted on the trailing edge of the body. Designed to have less gust sensitivity than the 737, the aileron segments are configured to deploy in an alternating up and down—or “crow-foot”— sequence to create vortex drag for yaw control and speed brake control.

“A big part of what we are designing here is the control mixer,” Buethe says, referring to the system that blends the input of all the aircraft control surfaces. Sized to carry about 250 passengers up to 5,000 nm, the Z4 main cabin has four major parallel compartments and additional premium seating in the forward section. Credit: JetZero

The flight deck also features BAE Systems-developed active side-stick controllers derived from systems on the Lockheed Martin F-35 and later introduced on Gulfstream G500/600 business jets. JetZero would be the first airliner/large transport to utilize the active sticks, which move together and improve feedback and situational awareness for the pilots.

While focusing on tailoring the flight control system for envelope protection, the JetZero approach is intended to combine the best of the control philosophies used by Airbus and Boeing. Airbus prioritizes pitch stability by providing automatic trim to maintain 1g flight, while Boeing focuses on speed stability.

“Airbus has no speed stability,” Buethe says. “That's great for up-and-away and normal flight but not so great for landing. We plan to have speed stability for takeoff and landing but not up-and-away. So we aren't locked into one thing for each phase of flight, we're going to have what's most appropriate for that phase of flight. We intend to blend the best of all worlds.

“If you have a private pilot's license and can fly a Cessna 172, you'll be able to fly this aircraft,” he adds. “And if you fly a Boeing or an Airbus or a business jet or a military jet, you will be able to jump in this aircraft and fly it from Day 1 without any difference.”

Validation of avionics hardware and software functionality, including interoperability, is underway in the Integration Test Facility (ITF). Based around a geometrically accurate cockpit, the ITF is configured with aircraft-equivalent wiring and powered by an aircraft-level electrical distribution system.

Developed with Michigan-based real-time test systems specialists Applied Dynamics International (ADI), the ITF builds on “some of the best practices that we could learn out of others we have done for companies like Rolls-Royce and some of the best practices from BAE Systems,” ADI President and CEO Scott James says.

“These labs are going to shorten this [test and development] program in a significant way,” James says. “Then when the aircraft moves into sustainment, these labs are going to be continuously busy as well.” In later phases, the ITF and Iron Bird, a related full-size mechanical systems test rig, “will be used as new software drops from the system suppliers come out,” he notes. “They may be used to solve bugs or maybe for revenue-generating upgrades for the aircraft. These labs will be used in a way that really minimizes the cost to the customer.”

“We are really relying on the ITF to move us along in the process,” JetZero avionics architecture engineer TeAnn Nguyen says. “We're using it all the way from software—how we think we want everything to work—to how we expect everything to work and then on to how it actually does work,” she says. “As we receive real line-replaceable units, we will use the brains of various systems like the fuel control computers, the flight control computers, the engine [full authority digital engine control] and so on. We can put those into the system, communicate with them directly as they would be on the aircraft and kind of work out those integration issues, as well as look at things like injecting faults.”

The ITF is more advanced than earlier facilities, Mason Gawler, simulation engineer and labs lead for JetZero, says. “[In previous integration facilities], you get behind schedule because of late hardware delivery, so you can only start testing when everything comes in,” he says. “But with this lab, we've simulated all those systems already that we haven't got in, so we can start integrating. For example, I'm sending air data exactly how the pitot tube will send it to the flight control computers right now, without the pitot tube being there.”

JetZero also is working on different structural solutions for the BWB's noncylindrical composite pressure vessel. “We're currently evaluating the trade space for options of different structural architectures that make the most sense,” Structures Manager Michael Galvin says. “Just like any other aircraft program, whatever we ultimately choose has to buy its way onto the airplane.” JetZero's Greensboro, North Carolina, facility is planned to eventually produce up to 20 Z4 BWBs per month. Credit: JetZero

Through a partnership with composites company Hexcel, along with the Wichita-based National Institute for Aviation Research, M4 Engineering and Mississippi State University's Advanced Composites Institute, JetZero is working under an FAA program to study the feasibility of using stitched-resin-infused composites on a Part 25 aircraft.

Building on the work conducted in the 2000s by Boeing and NASA under the Pultruded Rod Stitched Efficient Unitized Structure (Prseus) program, the FAA's Fueling Aviation's Sustainable Transition (FAST) program is targeted at supporting technologies for “advanced noncylindrical pressure-vessel designs at unprecedented production rates.”

Through Prseus, NASA and Boeing achieved a skin gauge 35% thinner than on the 787 with a stitched structure that was “fail safe” compared with the safe-life thicker laminate composite structures of today. Tests conducted on an 85%-scale BWB pressure vessel validated the strength and delamination resistance of the material and paved the way for the follow-on studies underway at JetZero.

“We haven't made any final decisions for architecture on the production variant of the aircraft, but we're evaluating the trade space of traditional pre-preg materials, out-of-autoclave materials and stitched resin-infused architecture as well,” Galvin says.

In the next few months, JetZero and Scaled Composites aim to have completed all major tooling, with external airframe design loads released around the same time. Final structure design release is expected in the third quarter. The nose section of the demonstrator is scheduled to be completed in early 2026; the wings and center and aft body should follow around midyear.

For manufacturing of the Z4, “we have a very conservative, metered approach to production,” Da Silva says. “We are looking at a five-year gradual production ramp-up, which may be six [years].

“If anybody gets into this business with the assumption that everything is going to go swimmingly and it's going to work exactly as planned, they are fools, so you have to go in with an optimistic approach but a realistic plan,” he adds.

Following a timescale roughly two years behind that of the demonstrator, JetZero provisionally plans to hold a CDR for the Z4 in mid-2027, leading to production prototypes around 2029. This first batch of aircraft is planned to be built at a rate of three per month, gradually expanding to five per month. The production rate is expected to continue to accelerate, so by the end of the fifth full year of production, the site could be making up to 20 aircraft per month.

“We believe 20 a month for an airplane of this size and complexity is very feasible in the first factory,” Da Silva says, adding that the production methodology is modeled on that of Airbus rather than Boeing. “One has production processes dating back to the 1940s; the other has production processes that were created in the 1970s,” he says. “The difference in technology between the two production processes allows Airbus to replicate factories and final assembly lines a lot easier than Boeing.

“Now imagine how much technology was created between 1974 and today, when they are able to build their production final assembly line with computing power and AI data mining,” he continues. “So we intend to create a production system that is repeatable in a very easy manner.”

JetZero is engaging digital assets to help with the design of the factory as well as the aircraft itself by using Siemens' Xcelerator open digital business platform.

“We are partnering with them on the design, simulation and development of the aircraft,” says Tom Tengan, director of digital enterprise at Siemens. “They are using our technology to augment their engineering and design teams so they can run the aircraft in a virtual development phase through its paces and verify that the aircraft works and is able to meet all of the requirements.”

Siemens also is working with the company on a tailored version of an aerospace digital thread. “The digital thread is the connected business elements of how a product goes through its life cycle and what information has to move from phase to phase of its development,” Tengan says. “We're working with JetZero to define that and make sure we have the data handoffs and connectivity throughout the life cycle as they design and simulate and validate their product.”

Siemens is helping JetZero plan the automation, layout and power requirements for the assembly site, too. This includes planning for “composites, fiber layup capabilities and the assembly capabilities required if they want to use automated guided vehicles, as well as moving tools and parts and components and subsystems around the factory,” Tengan says. “We are helping with traffic management of how everything in the factory is going to move, including the people on the shop floor, as well as safety around the robots and the robot cells for automated fiber placement and things of that nature.”

“Our plan is to build the factory in phases,” Da Silva notes. “We have Phase 1, which will support up to five a month, and then Phase 2 goes to 10 [per month]. Phase 3 goes to 20. You replicate the first line to go to 10, so you have two lines going, and then you replicate the same building to double the rate.”

JetZero plans to produce the center body and has issued requests for information to industry for what it calls the remaining “four corners”—the outer wings, cockpit and wedge empennage. “The center body, which is the fuselage-to-wing section, is where the big intellectual property is, so we will retain that no matter what,” Da Silva asserts. The four corner sections are “all simple pre-preg composites and things that other people have already done,” he adds.—With Steve Trimble and Joe Anselmo in Long Beach

In development under a $235 million cost-sharing U.S. Air Force contract awarded in 2023, the dual-role demonstrator is intended to provide the basis for the follow-on development of a new-generation military tanker-transport and a more efficient midmarket airliner.The demonstrator's design review is finalizedGreensboro, North Carolina, is selected for serial production

The startup acknowledges the huge task of building the demonstrator—an imposing twin-engine design with the same wingspan as a Boeing B-52. However, it is development of the proposed Z4 follow-on production model that begs the question: Can JetZero really pull this off?

The answer is an unequivocal “yes,” according to co-founder and CEO Tom O'Leary, who says JetZero is winning the battle for credibility by taking a pragmatic approach to testing, development, certification and production. Underpinning this strategy is the plan to use Part 25-certified and commercial-off-the-shelf components for about 80% of the aircraft's systems and equipment.

But reaching this stage has not been easy. Despite the potential for fuel-efficiency gains of up to 50% compared with current tube-and-wing designs and a 200-250-passenger midmarket sector largely ignored by Airbus and Boeing, JetZero's initial business plans were met with skepticism, O'Leary says.

Potential investors and supporters “would be looking at us and say: ‘What are you guys, like eight people? You do realize there's a global duopoly, right?' ” he recalls.

The challenge was “daunting, but not impossible,” he says. “So how did we turn that impossibility into inevitability? We went to the Air Force, and NASA helped us. They walked us into the Air Force, which was looking for a 21st-century airplane for a 21st-century problem, which is the tyranny of distance in the Pacific. The Air Force said: ‘We'd like to see a full-scale demonstration of this because that capability could really be a game-changer.' ”

Since the initial Air Force contract award in August 2023, JetZero's project has continued to gather momentum. Bolstered in April by the addition of United Airlines to the growing list of publicly named carriers—alongside Alaska Airlines and Delta Air Lines—willing to reveal an investment in the project, the company has focused on building a comprehensive group of industry suppliers and recruiting a team of experts covering everything from structures and systems to certification and manufacturing.

“We have over $300 million that's committed to the program,” O'Leary says. “We've spent barely half of what's been committed. To tap into all of the more than $150 million remaining, a lot of which comes from the Air Force, we do have financial milestones that we need to hit, and we're in the middle of raising our Series B funding to achieve those goals. That's going very well because we have a demand signal that's very strong and very clear.”

Operating in stealth mode for the first three years since its founding in 2020 by BWB veteran Mark Page and former Tesla and Beta Technologies executive O'Leary, the company expanded in 2024 into its current 285,000-ft.2, seven-building headquarters in Long Beach. The site is home to JetZero's business operations, design team, cabin lab, fabrication shop, scale-model program and aero labs—including a flying qualities lab, iron-bird systems test rig and integrated test facility.

Manufacturing of the demonstrator is underway at Northrop Grumman's Scaled Composites facility in Mojave, California. Serial production of the Z4 BWB will take place at a manufacturing and final assembly site in Greensboro, North Carolina. The site, which was announced in June after an exhaustive nationwide competition among 24 locations in 13 states, forms part of a $4.7 billion investment plan designed to create 14,500 regional aerospace jobs.

From a hardware perspective for the demonstrator, “we are much more advanced than you think,” says Florentina Viscotchi, head of engineering and formerly head of the Airbus A220 corporate jet program. Work has begun to lay out the composite structure of the cockpit, while the fuel tanks already are built. Among other components and assemblies under development, she adds: “The wing test article has been built, and now we are on the path to building that jig so we can build the final shape of the wing.” JetZero tests interoperability of electrical and electronic systems, including flight control computers and sidesticks, in its Integration Test Facility lab. Credit: JetZero

Design of the production version is underway in parallel, aided by input from JetZero's airline working group. “They give us feedback, and we take that into account in our product design. As a matter of fact, very soon, we will have a full baseline definition for that product, and that is an essential piece from which we continue driving trade studies,” Viscotchi says.

The working group's input already has informed meaningful changes to the configuration of both the demonstrator and production unit. For example, when JetZero completed a critical design review (CDR) of the demonstrator in May, it incorporated key changes to simplify the landing gear configuration made at the behest of the group.

The revised gear arrangement sees the main landing gear legs moved forward and a conventional design replacing the originally proposed articulating pivot-gear nose leg. JetZero says the changes, which will be validated in upcoming wind tunnel tests, will not delay flight tests of the proof-of-concept BWB aircraft in late 2027.

Page conceived the pivot-gear concept, originally called the pivot piston, to solve a conundrum facing BWB designs. Due to their short moment arm in pitch, blended-wing configurations require the main landing gear to be near the center of gravity (CG) for takeoff rotation. Although this improves low-speed pitch authority, the internal area used for stowage of the main and nose gears dramatically increases the overall depth of the aircraft, making it too big and heavy for the single-aisle or midsize market.

By pivoting the nose gear, the design enabled the main gear to be moved farther aft, behind the cabin-pressure vessel rather than beneath it, freeing up space to allow a single deck configuration. On takeoff, the nose gear is designed to pivot and extend, raising the nose and creating extra lift from the body, which allows the aircraft to rotate around a “virtual” CG with minimal elevon download forces.

But the airlines within its advisory group wanted a simpler design, JetZero President and Chief Operating Officer Dan Da Silva says. “The more we talked to the FAA and the airlines, everybody was ‘derisk, derisk, derisk,'” he notes. “So we looked at moving the main gear forward, closer to the CG of the airplane.”

The additional lift from the body still “will enable liftoff speed to be slower, reducing demand for high takeoff thrust,” says the head of flight sciences, Hsin-Yi Yen. He explains that the initial design will meet its performance goals with relatively small trailing-edge flaps and without the need for leading-edge high-lift slats.

Although the new configuration will require an internal redesign for the production model, JetZero faces fewer gear-retraction design restrictions on the demonstrator, which has been designed purely for proving the BWB's aerodynamic qualities and does not carry any payload. The “Franken-demonstrator” will incorporate systems and components from several existing aircraft, including main landing gear from a McDonnell Douglas MD-11, nose gear and Pratt & Whitney PW2040 engines from a Boeing 757 and a hybrid electrical system combining elements from a Boeing 767 and Boeing C-17.

“We're iterating on the production airplane design,” Da Silva says. “We still want to keep the same thickness, and we have a lot of potential to move up the passenger floor and create space underneath. So it is still a single deck, but it does have a half-deck under it, which could fit the landing gear as well as LD3-45 containers.” Such cargo containers are used in the Airbus A320/A321.

The pivot nose gear remains an option for future proposed follow-on Z3-family variants in the A320-Boeing 737 single-aisle replacement class. “We may go back to that design on a smaller-scale airplane, but at the size that we're at [with the Z4,] the articulating nose gear was very big and complex and heavy,” Da Silva says. “We had a very workable design, and it works really well. We're about to test another scale version of it.”

Creation of additional lower deck space also may help to answer other questions posed by the working group. “Airlines have given us feedback because in the single-deck configuration: You must load bags into the ‘armpit' of the airplane, and you can't load it all from one side. You need to have two loaders,” Da Silva says. “From an airline ground-operations perspective, it is a little bit more of a challenge. So they tasked us to find different solutions.”

Further details of the redesign will be unveiled after completion of the CDR. Operators “will be pleased with the outcome of that decision,” Viscotchi says. “I can't tell you more at this point, but we do have that configuration nailed down. This is the configuration that will be used for the demonstrator, as well as for the product.”

JetZero also is discussing propulsion options for the production version with engine suppliers including Pratt & Whitney, which is providing PW2040s for the demonstrator. BWB engine concepts also were presented by GE Aerospace-CFM International, Rolls-Royce and Kratos-owned FTT at JetZero's recent airline advisory group meeting.

Although Pratt appears to be in a leading position to supply the powerplant for the initial production aircraft, Viscotchi says the goal is to offer a choice of engines. “We've also heard loud and clear from those airlines that a dual-engine source is a very important item to consider,” she says. Citing her previous experience working on the A220, which is exclusively powered by Pratt, Viscotchi notes that offering a choice “allows me to keep that guy on their toes.”

JetZero is asking engine-makers for propulsion systems that are optimized for top-of-climb thrust to suit a balanced power demand from takeoff to cruise altitudes of up to 45,000 ft. This, in turn, calls for engines with lower bypass ratios than the latest generation of turbofans, in service ones, in development or ones under study for aircraft in the 2030s.

Although seemingly counterintuitive in an age of ever-increasing bypass ratios, the company says a lower bypass better meets the aircraft's performance goals while achieving the design limit of 80% maximum continuous thrust. Any noise and cruise efficiency penalties are compensated for by airframe shielding and the BWB's lift-drag performance, JetZero says.

“A lower-bypass-ratio engine works better for us,” Da Silva says, emphasizing that the requirement is “not a low bypass, but lower.” The target is in the 6.5:1-8:1 bypass-ratio range. “That's perfectly fine,” he notes. “We don't need to go to 11:1-13:1, which is great for mid-30s cruise [35,000 ft.] and maybe a maximum takeoff weight [MTOW] of 180,000-200,000 lb. We are going be around 280,000-290,000 lb. MTOW on the production airplane, and we want to fly at 45,000 ft., so more like a Gulfstream.”

The Z4 engines will be the first commercial airliner turbofans to be mounted over-wing since the Rolls-Royce-Snecma M45 on the VFW614 regional jet. While both the VFW614 and the more recently developed GE Aerospace-Honda HF120-powered HA-420 HondaJet business aircraft were designed with a single strut mount, the Z4 engine will be supported on a split pylon with a gap between the struts for boundary layer diversion.

The semiburied nacelles are designed to prevent inlet distortion by channeling the boundary layer beneath the engine. Although some of the boundary layer still may be ingested at high thrust and low airspeed, the exit of the diverter is positioned below the nozzle, where it will draw a vacuum, enabling the diverter intake flow rate to match that of the engine inlet.

Final design release for the nacelle is scheduled for mid-2026, and the finished product is expected to be ready for installation on the demonstrator in early 2027. JetZero says it also is working with Pratt and the airline group on methods for servicing the engine on the Z4. Large side-of-body structural members, represented in the Z4 cabin mockup, indicate the interface area between the noncylindrical cabin pressure vessel and the wing. Credit: Guy Norris/AW&ST

Through 2024 and early 2025, the focus for aerodynamic testing has been on a series of subscale aircraft, data from which continues to be fed into the flying qualities lab for flight controls development. Initial work through the first part of this year included tests of Subscale Vehicle (SV) 1, in which the first 6.25%-scale BWB model was attached to the back of a truck for open-air, high-speed runs.

“It's like a moving wind tunnel,” Da Silva says. “It allows us to do a lot of the tests that you would do in a wind tunnel by running a truck up and down the runway. Long Beach Airport has been very collaborative with us. They shut down a taxiway, and we can go up and down at 60-plus mph with a big, 11-ft.-wingspan airplane attached to the back of a pickup truck.”

JetZero's decision to refocus on the smaller SV test series comes after the loss of the larger and more expensive 12.5%-scale air vehicle (AV-1) in a battery fire following its first flight in June 2024. AV-1 was designed to inform the development of flight controls. “We can do all that in a 6.25% model at one-eighth the cost,” Da Silva says. “So that allows us to build multiple models, experiment as we go and fly at a higher tempo.

“We're targeting about mid-July for when we feel that we have all the control laws and configuration firmed up on the SV program,” he continues. “Then we can choose to fly the second 12.5%-scale vehicle, AV-2, or not.”

Results will be incorporated into the overall aerodynamic database, with contributions coming from further low- and high-speed wind tunnel tests planned for this year and early in 2026.

Aerodynamic data from refined computational fluid dynamics analysis scheduled for the third quarter of 2025 also will be fed into the flying qualities lab. This will be augmented with results from the high-speed wind tunnel work scheduled for early next year, leading to the planned completion of flight control law tests before mid-2026.

The flying qualities lab enables rapid prototyping of flight control software and “ensures we can develop a very safe pilot-in-the-loop fly-by-wire flight control system,” control law engineer Gerald Arzoumanian says. “By ‘safe,' in this case we mean to have precise handling qualities and low pilot workload in normal or abnormal conditions.”

Veteran flight control law developer and test pilot Scott Buethe, who will fly the demonstrator along with former Virgin Orbit test pilot Mathew Stannard, says the BWB flight control architecture incorporates several special features. “We've designed the flight control system so that you can introduce side slip, and it basically just keeps the wings level for you,” Buethe says. “So we decoupled yaw and roll.”

Although tailless in the conventional sense, the BWB will have wingtip-mounted vertical rudders, two sets of multisegment ailerons inboard and outboard and elevators mounted on the trailing edge of the body. Designed to have less gust sensitivity than the 737, the aileron segments are configured to deploy in an alternating up and down—or “crow-foot”— sequence to create vortex drag for yaw control and speed brake control.

“A big part of what we are designing here is the control mixer,” Buethe says, referring to the system that blends the input of all the aircraft control surfaces. Sized to carry about 250 passengers up to 5,000 nm, the Z4 main cabin has four major parallel compartments and additional premium seating in the forward section. Credit: JetZero

The flight deck also features BAE Systems-developed active side-stick controllers derived from systems on the Lockheed Martin F-35 and later introduced on Gulfstream G500/600 business jets. JetZero would be the first airliner/large transport to utilize the active sticks, which move together and improve feedback and situational awareness for the pilots.

While focusing on tailoring the flight control system for envelope protection, the JetZero approach is intended to combine the best of the control philosophies used by Airbus and Boeing. Airbus prioritizes pitch stability by providing automatic trim to maintain 1g flight, while Boeing focuses on speed stability.

“Airbus has no speed stability,” Buethe says. “That's great for up-and-away and normal flight but not so great for landing. We plan to have speed stability for takeoff and landing but not up-and-away. So we aren't locked into one thing for each phase of flight, we're going to have what's most appropriate for that phase of flight. We intend to blend the best of all worlds.

“If you have a private pilot's license and can fly a Cessna 172, you'll be able to fly this aircraft,” he adds. “And if you fly a Boeing or an Airbus or a business jet or a military jet, you will be able to jump in this aircraft and fly it from Day 1 without any difference.”

Validation of avionics hardware and software functionality, including interoperability, is underway in the Integration Test Facility (ITF). Based around a geometrically accurate cockpit, the ITF is configured with aircraft-equivalent wiring and powered by an aircraft-level electrical distribution system.

Developed with Michigan-based real-time test systems specialists Applied Dynamics International (ADI), the ITF builds on “some of the best practices that we could learn out of others we have done for companies like Rolls-Royce and some of the best practices from BAE Systems,” ADI President and CEO Scott James says.

“These labs are going to shorten this [test and development] program in a significant way,” James says. “Then when the aircraft moves into sustainment, these labs are going to be continuously busy as well.” In later phases, the ITF and Iron Bird, a related full-size mechanical systems test rig, “will be used as new software drops from the system suppliers come out,” he notes. “They may be used to solve bugs or maybe for revenue-generating upgrades for the aircraft. These labs will be used in a way that really minimizes the cost to the customer.”

“We are really relying on the ITF to move us along in the process,” JetZero avionics architecture engineer TeAnn Nguyen says. “We're using it all the way from software—how we think we want everything to work—to how we expect everything to work and then on to how it actually does work,” she says. “As we receive real line-replaceable units, we will use the brains of various systems like the fuel control computers, the flight control computers, the engine [full authority digital engine control] and so on. We can put those into the system, communicate with them directly as they would be on the aircraft and kind of work out those integration issues, as well as look at things like injecting faults.”

The ITF is more advanced than earlier facilities, Mason Gawler, simulation engineer and labs lead for JetZero, says. “[In previous integration facilities], you get behind schedule because of late hardware delivery, so you can only start testing when everything comes in,” he says. “But with this lab, we've simulated all those systems already that we haven't got in, so we can start integrating. For example, I'm sending air data exactly how the pitot tube will send it to the flight control computers right now, without the pitot tube being there.”

JetZero also is working on different structural solutions for the BWB's noncylindrical composite pressure vessel. “We're currently evaluating the trade space for options of different structural architectures that make the most sense,” Structures Manager Michael Galvin says. “Just like any other aircraft program, whatever we ultimately choose has to buy its way onto the airplane.” JetZero's Greensboro, North Carolina, facility is planned to eventually produce up to 20 Z4 BWBs per month. Credit: JetZero

Through a partnership with composites company Hexcel, along with the Wichita-based National Institute for Aviation Research, M4 Engineering and Mississippi State University's Advanced Composites Institute, JetZero is working under an FAA program to study the feasibility of using stitched-resin-infused composites on a Part 25 aircraft.

Building on the work conducted in the 2000s by Boeing and NASA under the Pultruded Rod Stitched Efficient Unitized Structure (Prseus) program, the FAA's Fueling Aviation's Sustainable Transition (FAST) program is targeted at supporting technologies for “advanced noncylindrical pressure-vessel designs at unprecedented production rates.”

Through Prseus, NASA and Boeing achieved a skin gauge 35% thinner than on the 787 with a stitched structure that was “fail safe” compared with the safe-life thicker laminate composite structures of today. Tests conducted on an 85%-scale BWB pressure vessel validated the strength and delamination resistance of the material and paved the way for the follow-on studies underway at JetZero.

“We haven't made any final decisions for architecture on the production variant of the aircraft, but we're evaluating the trade space of traditional pre-preg materials, out-of-autoclave materials and stitched resin-infused architecture as well,” Galvin says.

In the next few months, JetZero and Scaled Composites aim to have completed all major tooling, with external airframe design loads released around the same time. Final structure design release is expected in the third quarter. The nose section of the demonstrator is scheduled to be completed in early 2026; the wings and center and aft body should follow around midyear.

For manufacturing of the Z4, “we have a very conservative, metered approach to production,” Da Silva says. “We are looking at a five-year gradual production ramp-up, which may be six [years].

“If anybody gets into this business with the assumption that everything is going to go swimmingly and it's going to work exactly as planned, they are fools, so you have to go in with an optimistic approach but a realistic plan,” he adds.

Following a timescale roughly two years behind that of the demonstrator, JetZero provisionally plans to hold a CDR for the Z4 in mid-2027, leading to production prototypes around 2029. This first batch of aircraft is planned to be built at a rate of three per month, gradually expanding to five per month. The production rate is expected to continue to accelerate, so by the end of the fifth full year of production, the site could be making up to 20 aircraft per month.

“We believe 20 a month for an airplane of this size and complexity is very feasible in the first factory,” Da Silva says, adding that the production methodology is modeled on that of Airbus rather than Boeing. “One has production processes dating back to the 1940s; the other has production processes that were created in the 1970s,” he says. “The difference in technology between the two production processes allows Airbus to replicate factories and final assembly lines a lot easier than Boeing.

“Now imagine how much technology was created between 1974 and today, when they are able to build their production final assembly line with computing power and AI data mining,” he continues. “So we intend to create a production system that is repeatable in a very easy manner.”

JetZero is engaging digital assets to help with the design of the factory as well as the aircraft itself by using Siemens' Xcelerator open digital business platform.

“We are partnering with them on the design, simulation and development of the aircraft,” says Tom Tengan, director of digital enterprise at Siemens. “They are using our technology to augment their engineering and design teams so they can run the aircraft in a virtual development phase through its paces and verify that the aircraft works and is able to meet all of the requirements.”

Siemens also is working with the company on a tailored version of an aerospace digital thread. “The digital thread is the connected business elements of how a product goes through its life cycle and what information has to move from phase to phase of its development,” Tengan says. “We're working with JetZero to define that and make sure we have the data handoffs and connectivity throughout the life cycle as they design and simulate and validate their product.”

Siemens is helping JetZero plan the automation, layout and power requirements for the assembly site, too. This includes planning for “composites, fiber layup capabilities and the assembly capabilities required if they want to use automated guided vehicles, as well as moving tools and parts and components and subsystems around the factory,” Tengan says. “We are helping with traffic management of how everything in the factory is going to move, including the people on the shop floor, as well as safety around the robots and the robot cells for automated fiber placement and things of that nature.”

“Our plan is to build the factory in phases,” Da Silva notes. “We have Phase 1, which will support up to five a month, and then Phase 2 goes to 10 [per month]. Phase 3 goes to 20. You replicate the first line to go to 10, so you have two lines going, and then you replicate the same building to double the rate.”

JetZero plans to produce the center body and has issued requests for information to industry for what it calls the remaining “four corners”—the outer wings, cockpit and wedge empennage. “The center body, which is the fuselage-to-wing section, is where the big intellectual property is, so we will retain that no matter what,” Da Silva asserts. The four corner sections are “all simple pre-preg composites and things that other people have already done,” he adds.—With Steve Trimble and Joe Anselmo in Long Beach

Share

Recent Chats

Share via email

Future: handle WhatsApp here

Future: handle LinkedIn here

Future: handle Twitter here

SUBMENU HERE

Share via Chat

Copy Link