Ultra-Precision Grinding Machines

±2μm accuracy for aerospace, defense, robotics, and semiconductor components.

High Frequency Spindles

30,000–120,000 rpm spindles in belt-driven, built-in motor, hydrostatic, and hydrodynamic types.

Comprehensive Machine Lineup

Centerless, double-disc, thread, cylindrical, and special-purpose grinders for key parts.

Global Retrofit & Service

25+ years in spindle repair and retrofit, extending machine life and reducing downtime.

ORSKOREA

ORSKOREA delivers ultra-precision grinding machines and high-frequency spindles for aerospace, defense, robotics, and advanced mobility. With ±2μm accuracy and proven reliability, we enable the machining of critical high-value components.

Masanhoewon-gu, Changwon-si, Gyeongsangnam-do, South Korea

Aerospace

Products & Services

People

News

Other

About

Products & Services

Centerless ginding machines (SGC 300)

ORSKOREA

ORSKOREA’s centerless grinding machines ensure stable accuracy and durability without the need for chucks or centers. By allowing workpieces to rotate freely between the grinding and regulating wheels, they deliver high-efficiency and uniform machining for shafts, pins, housings, and other cylindrical components used in aerospace, defense, and advanced automotive systems.

Key Advantages

• High productivity through fast, efficient multi-part processing

• ±2μm precision and long-term repeatability

• Versatility to handle components from small to large sizes

• Hydrostatic slides and spindles minimizing heat and vibration

• Proven stability for high-value part manufacturing such as engine components, battery cases, and optical housings

By combining productivity, accuracy, and reliability, ORSKOREA’s centerless grinders significantly enhance competitiveness in both defense and civilian applications.

Key Advantages

• High productivity through fast, efficient multi-part processing

• ±2μm precision and long-term repeatability

• Versatility to handle components from small to large sizes

• Hydrostatic slides and spindles minimizing heat and vibration

• Proven stability for high-value part manufacturing such as engine components, battery cases, and optical housings

By combining productivity, accuracy, and reliability, ORSKOREA’s centerless grinders significantly enhance competitiveness in both defense and civilian applications.

Universal cylindrical grinding machines(SGU35)

ORSKOREA

ORSKOREA’s cylindrical grinding machines are engineered to deliver superior surface quality and tight tolerances for high-value parts. They are widely used in aerospace, defense, automotive, medical, and electronics industries for components that demand both strength and precision—such as engine shafts, landing gear parts, gears, and bearings.

Key Advantages

• Handles diverse, small-batch productions with consistent repeatability

• Exceptional dimensional precision for tight-tolerance parts

• Supports tapered and curved surface grinding

• Flexible workpiece capacity with swing up to 350 mm

• Smooth table movement with low noise and vibration for stable operation

By combining precision, versatility, and long-term reliability, ORSKOREA’s cylindrical grinders provide manufacturers with the performance needed to meet mission-critical requirements.

Key Advantages

• Handles diverse, small-batch productions with consistent repeatability

• Exceptional dimensional precision for tight-tolerance parts

• Supports tapered and curved surface grinding

• Flexible workpiece capacity with swing up to 350 mm

• Smooth table movement with low noise and vibration for stable operation

By combining precision, versatility, and long-term reliability, ORSKOREA’s cylindrical grinders provide manufacturers with the performance needed to meet mission-critical requirements.

Screw external/internal thread grinding machine(SGTE .SGTI)

ORSKOREA

ORSKOREA’s thread grinding machines are designed for high-precision machining of both internal and external threads, covering a wide range of thread profiles and dimensions. These machines are critical for producing aerospace fasteners, defense system parts, precision ball screws, and other components where accuracy and durability are vital.

Key Advantages

• CNC Control: 4-axis (SGTE) and 5-axis (SGTI) for complex thread profiles

• High-rigidity structure minimizing vibration and thermal distortion

• Built-in dressing and balancing units for consistent quality

By shortening processes and improving efficiency, ORSKOREA’s thread grinders reduce costs while enabling high-value, high-accuracy production. They also serve as advanced domestic alternatives to imported machines, strengthening localization and export competitiveness.

Key Advantages

• CNC Control: 4-axis (SGTE) and 5-axis (SGTI) for complex thread profiles

• High-rigidity structure minimizing vibration and thermal distortion

• Built-in dressing and balancing units for consistent quality

By shortening processes and improving efficiency, ORSKOREA’s thread grinders reduce costs while enabling high-value, high-accuracy production. They also serve as advanced domestic alternatives to imported machines, strengthening localization and export competitiveness.

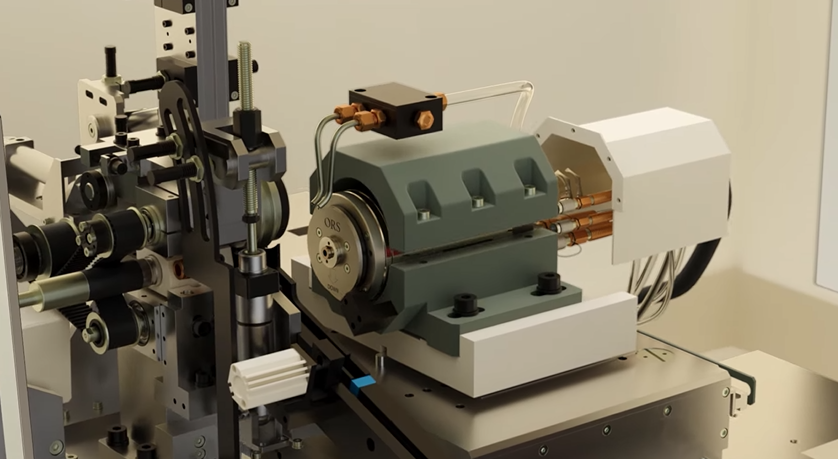

High Frequency Spindle

ORSKOREA

ORSKOREA’s high frequency grinding spindles, operating at speeds up to 120,000 rpm—the highest level in Korea—are engineered for ultra-precision and durability in critical defense and aerospace applications. In addition to belt-driven, built-in motor, hydrostatic, and hydrodynamic types widely used in semiconductor and precision equipment, our spindles are customized to deliver the exact speed and power output required by customers. With over 25 years of expertise in repairing and retrofitting leading Japanese, German, and Swiss brands such as TOYO, KOYO, OKUMA, GMN, and Fischer, and with multiple proprietary patents including joint developments with Schaeffler Korea, ORSKOREA ensures proven reliability. These spindles are ideal for machining high-value defense components such as armored vehicle gears, drone actuators, aircraft engine parts, multispectral sensor housings, and advanced optical or communication devices, supporting the competitiveness of both defense and civilian manufacturers.

People

Gyuhyun SHIM

ORSKOREA

Junior Mechanical Engineer

Irene(Jaemin) KIM

ORSKOREA

AI Specialist

Lidia (Soeyeong) SHIM

ORSKOREA

Strategic Business Manager

Seokbeom KANG

ORSKOREA

Junior Production Manager

Seonghyeon SON

ORSKOREA

Marketing Specialist

Yasin ÖZDEMIR

ORSKOREA

Global Sales Representative

Youjin SHIM

ORSKOREA

Marketing Specialist

News

What Makes a 120,000 rpm Spindle Stay Stable?

[The Rise of High-Frequency Spindles in Ultra-Precision Manufacturing]

As the demand for high-precision and high-speed machining continues to grow across industries such as aerospace, semiconductors, precision mold manufacturing, and medical devices, high-frequency spindles are emerging as a critical component in advanced machinery.

Because they must deliver both ultra-fast rotational speeds and exceptionally low vibration, high-frequency spindles are considered among the most precise parts within a machine — directly impacting the quality and productivity of the equipment itself.

[ORSKOREA’s SHS Series: Designed for Precision, Built for Trust]

With over 30 years of experience in spindle maintenance and in-house development, backed by patented technologies, ORSKOREA has designed the SHS Series of high-frequency spindles to meet the evolving demands of precision manufacturing.

The SHS Series offers the following key technical features:

- A minimal-component design for easier maintenance

- Patented thermal and vibration control technology

- Wide speed range from 30,000 rpm to 120,000 rpm

- Ultra-low vibration levels, ranging from 0.5mm to 0.8mm/sec

- Customizable configurations tailored to specific machining conditions

ORSKOREA’s high-frequency spindles deliver both high-speed rotation and ultra-precise machining, adapting seamlessly to a wide range of processes across domestic and global customer environments.

As the demand for high-precision and high-speed machining continues to grow across industries such as aerospace, semiconductors, precision mold manufacturing, and medical devices, high-frequency spindles are emerging as a critical component in advanced machinery.

Because they must deliver both ultra-fast rotational speeds and exceptionally low vibration, high-frequency spindles are considered among the most precise parts within a machine — directly impacting the quality and productivity of the equipment itself.

[ORSKOREA’s SHS Series: Designed for Precision, Built for Trust]

With over 30 years of experience in spindle maintenance and in-house development, backed by patented technologies, ORSKOREA has designed the SHS Series of high-frequency spindles to meet the evolving demands of precision manufacturing.

The SHS Series offers the following key technical features:

- A minimal-component design for easier maintenance

- Patented thermal and vibration control technology

- Wide speed range from 30,000 rpm to 120,000 rpm

- Ultra-low vibration levels, ranging from 0.5mm to 0.8mm/sec

- Customizable configurations tailored to specific machining conditions

ORSKOREA’s high-frequency spindles deliver both high-speed rotation and ultra-precise machining, adapting seamlessly to a wide range of processes across domestic and global customer environments.

18 Sep 2025

What is a Centerless Grindnig Machine?

[What is a Centerless Grindnig Machine?]

A centerless grinding machine, as the name implies, is a grinding method that operates without a center support. Instead of being fixed by a chuck or center, the workpiece rotates freely while the grinding wheel precisely refines its surface to achieve the desired shape. This process is highly effective in maintaining clean and uniform diameters and surfaces.

Centerless grinding machines are widely used for circular parts and are particularly optimized for machining the outer diameters of cylindrical components.

[Advantage of Centerless Grinding Machine]

- High Productivity

- Precise Grinding Performance

- Versatile Grinding for a Wide Range of Components

[Tailored to Your Manufacturing Needs :From Small to Large Parts]

The SGC series includes models designed for various workpiece sizes.

- SGC 200 and SGC 300 feature a relatively narrow regulating wheel, making them ideal for small to medium-sized parts.

- SGC 500, SGC 500K, and SGC 500C have a wider regulating wheel, allowing for efficient processing of large or heavy components.

A centerless grinding machine, as the name implies, is a grinding method that operates without a center support. Instead of being fixed by a chuck or center, the workpiece rotates freely while the grinding wheel precisely refines its surface to achieve the desired shape. This process is highly effective in maintaining clean and uniform diameters and surfaces.

Centerless grinding machines are widely used for circular parts and are particularly optimized for machining the outer diameters of cylindrical components.

[Advantage of Centerless Grinding Machine]

- High Productivity

- Precise Grinding Performance

- Versatile Grinding for a Wide Range of Components

[Tailored to Your Manufacturing Needs :From Small to Large Parts]

The SGC series includes models designed for various workpiece sizes.

- SGC 200 and SGC 300 feature a relatively narrow regulating wheel, making them ideal for small to medium-sized parts.

- SGC 500, SGC 500K, and SGC 500C have a wider regulating wheel, allowing for efficient processing of large or heavy components.

18 Sep 2025

What Is an Internal Thread Grinding Machine?

[What Is an Internal Thread Grinding Machine?]

An internal thread grinding machine is a specialized machine designed to precisely grind internal threads inside components. Compared to external thread grinding, internal thread grinding is far more demanding in terms of machining conditions and precision, requiring advanced technology and highly stable equipment.

Internal thread grinding Machines are mainly used for grinding fastener components in the aerospace and defense sectors, reducer components used in humanoid robots, and ball screws, which are experiencing growing demand in the automotive industry.

[ORSKOREA SGTI-80: A New Standard in Internal Thread Grinding]

The SGTI-80 is ORSKOREA’s independently developed high-precision internal thread grinding machine, designed as an optimal solution for domestic and global precision part manufacturers.

Key Features:

- 5-axis servo control system enabling precise grinding of complex thread profiles

- High-rigidity structure minimizing vibration and thermal distortion

- Built-in automated dressing and balancing units

- High-speed table feed system maximizing productivity

- Dual-process capability allowing two operations on a single machine, improving efficiency and reducing costs

An internal thread grinding machine is a specialized machine designed to precisely grind internal threads inside components. Compared to external thread grinding, internal thread grinding is far more demanding in terms of machining conditions and precision, requiring advanced technology and highly stable equipment.

Internal thread grinding Machines are mainly used for grinding fastener components in the aerospace and defense sectors, reducer components used in humanoid robots, and ball screws, which are experiencing growing demand in the automotive industry.

[ORSKOREA SGTI-80: A New Standard in Internal Thread Grinding]

The SGTI-80 is ORSKOREA’s independently developed high-precision internal thread grinding machine, designed as an optimal solution for domestic and global precision part manufacturers.

Key Features:

- 5-axis servo control system enabling precise grinding of complex thread profiles

- High-rigidity structure minimizing vibration and thermal distortion

- Built-in automated dressing and balancing units

- High-speed table feed system maximizing productivity

- Dual-process capability allowing two operations on a single machine, improving efficiency and reducing costs

17 Sep 2025

What is a Cylindrical Grinding Machine?

[What is a Cylindrical Grinding Machine?]

A cylindrical grinding machine is a specialized tool used to grind the outer or inner surfaces of cylindrical or conical components. The primary purpose of cylindrical grinding is to improve the surface quality of the circular workpiece and achieve precise tolerances.

Work pieces processed on lathes or CNC lathes often have insufficient surface roughness Ra values. Thus, a cylindrical grinding machine is needed in various industrial fields where precision and surface quality are critical.

[Applications of Cylindrical Grinding Machines]

Aerospace Industry :

Machining durable, high-precision parts such as turbine blades and landing gear.

Automotive Industry :

Grinding high-precision components like engine parts, gears, and bearings.

Electronics Industry :

Crafting high-precision parts for semiconductor manufacturing equipment.

[Advantages of Cylindrical Grinding Machines]

- Ideal for Diverse yet Small-Batch Productions

- High-precision Dimensional Capability

- Capability for Tapered and Curved Grinding

- Length Versatility

- Efficient Grinding Wheel Reuse

- Smooth Table Movement and Low Noise and Vibration

[Key Features of ORSKOREA Cylindrical Grinding Machine?]

- Swing Capacity Up To 350mm

- Hydrodynamic or Hydrostatic Spindle Options

- Mineral Casting Bed Options for Enhanced Stability

- Multi Workhead & Adjustable Tailstock for Flexibility

A cylindrical grinding machine is a specialized tool used to grind the outer or inner surfaces of cylindrical or conical components. The primary purpose of cylindrical grinding is to improve the surface quality of the circular workpiece and achieve precise tolerances.

Work pieces processed on lathes or CNC lathes often have insufficient surface roughness Ra values. Thus, a cylindrical grinding machine is needed in various industrial fields where precision and surface quality are critical.

[Applications of Cylindrical Grinding Machines]

Aerospace Industry :

Machining durable, high-precision parts such as turbine blades and landing gear.

Automotive Industry :

Grinding high-precision components like engine parts, gears, and bearings.

Electronics Industry :

Crafting high-precision parts for semiconductor manufacturing equipment.

[Advantages of Cylindrical Grinding Machines]

- Ideal for Diverse yet Small-Batch Productions

- High-precision Dimensional Capability

- Capability for Tapered and Curved Grinding

- Length Versatility

- Efficient Grinding Wheel Reuse

- Smooth Table Movement and Low Noise and Vibration

[Key Features of ORSKOREA Cylindrical Grinding Machine?]

- Swing Capacity Up To 350mm

- Hydrodynamic or Hydrostatic Spindle Options

- Mineral Casting Bed Options for Enhanced Stability

- Multi Workhead & Adjustable Tailstock for Flexibility

17 Sep 2025

About

[Company Profile]

ORSKOREA is a precision machine tool and spindle manufacturer with over 30 years of expertise, serving aerospace/defense, robotics, and future mobility industries.

We specialize in high-precision grinding machines such as centerless, thread, and special-purpose grinders, delivering ±2μm accuracy and stable reproducibility for critical defense and aerospace parts.

Our spindle lineup, including high-speed spindles up to 120,000 rpm, supports demanding applications from semiconductors to robotic joints.

With over 80% of sales from exports, we partner with leading global manufacturers to expand localization and enhance international competitiveness.

[Main Products and Services]

ORSKOREA manufactures precision grinding machines including centerless, double disc, internal/external thread, superfinishing, and cylindrical grinders. Our machines ensure machining accuracy and stable reproducibility, making them suitable for aerospace and defense components such as ball screws, gears, and bearings. Proprietary spindles operate from 30,000 to 120,000 RPM and cover high-frequency, ultra-precision, belt-driven, built-in motor, hydrostatic, and hydrodynamic types, addressing demanding applications in aerospace, defense, robotics, and semiconductor industries. In addition to new machines, ORSKOREA offers over 25 years of experience in spindle repair and retrofit for leading Japanese, German, and Swiss brands, providing solutions that extend equipment life, minimize downtime, and enhance productivity.

ORSKOREA is a precision machine tool and spindle manufacturer with over 30 years of expertise, serving aerospace/defense, robotics, and future mobility industries.

We specialize in high-precision grinding machines such as centerless, thread, and special-purpose grinders, delivering ±2μm accuracy and stable reproducibility for critical defense and aerospace parts.

Our spindle lineup, including high-speed spindles up to 120,000 rpm, supports demanding applications from semiconductors to robotic joints.

With over 80% of sales from exports, we partner with leading global manufacturers to expand localization and enhance international competitiveness.

[Main Products and Services]

ORSKOREA manufactures precision grinding machines including centerless, double disc, internal/external thread, superfinishing, and cylindrical grinders. Our machines ensure machining accuracy and stable reproducibility, making them suitable for aerospace and defense components such as ball screws, gears, and bearings. Proprietary spindles operate from 30,000 to 120,000 RPM and cover high-frequency, ultra-precision, belt-driven, built-in motor, hydrostatic, and hydrodynamic types, addressing demanding applications in aerospace, defense, robotics, and semiconductor industries. In addition to new machines, ORSKOREA offers over 25 years of experience in spindle repair and retrofit for leading Japanese, German, and Swiss brands, providing solutions that extend equipment life, minimize downtime, and enhance productivity.

Add Attachment

Share

Recent Chats

Share via email

Future: handle WhatsApp here

Future: handle LinkedIn here

Future: handle Twitter here

SUBMENU HERE

Share via Chat

Copy Link